Fabricated rotor rare-earth permanent magnet torque motor

A permanent magnet force, assembled technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the difficulty in realizing the application of rare earth permanent magnet torque motor, restricting the development of rare earth permanent magnet torque motor, magnetic leakage and Permanent demagnetization has no problems such as more improvement, and achieves the effect of improving oil production efficiency and economic benefits of oil wells, improving manufacturing and assembly process, and improving structural safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

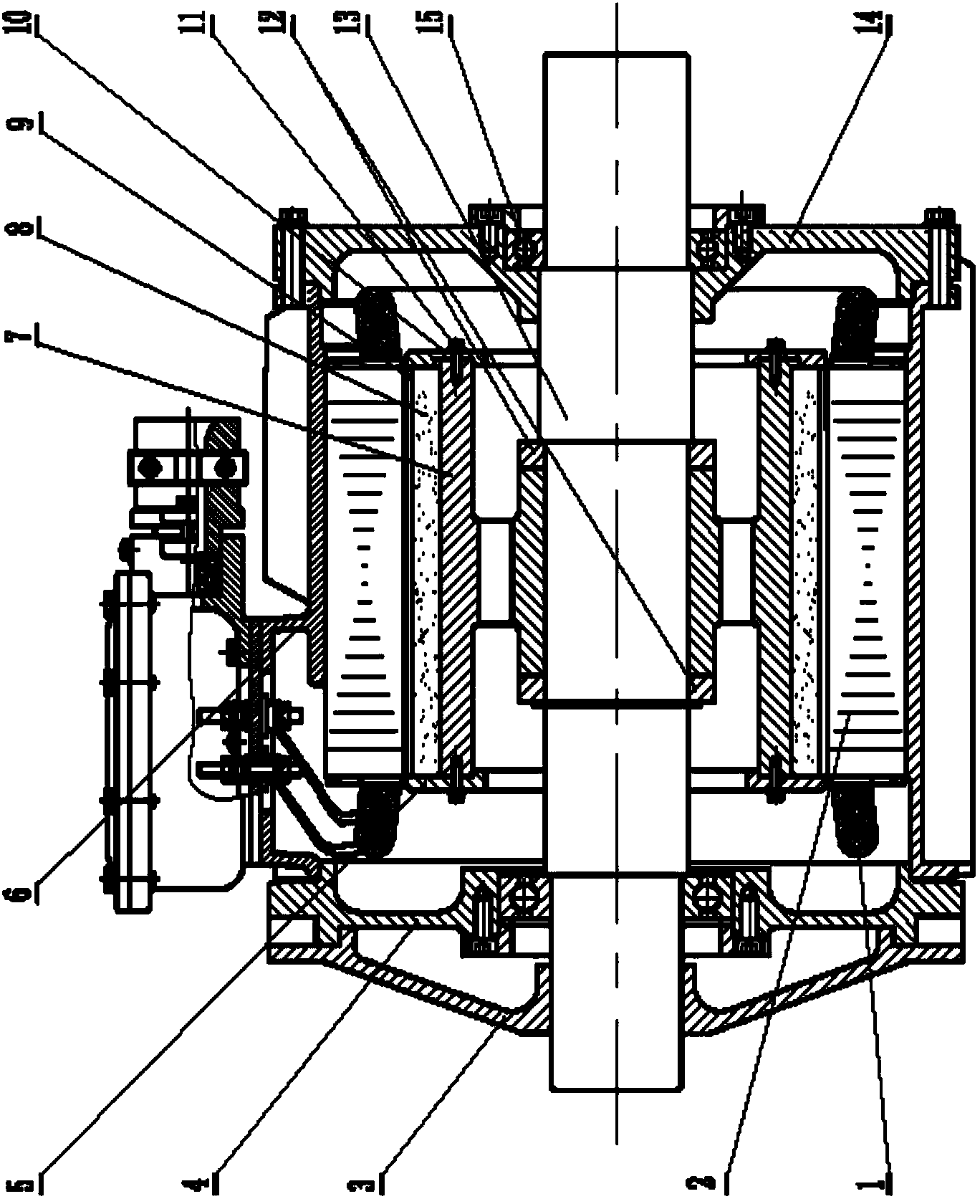

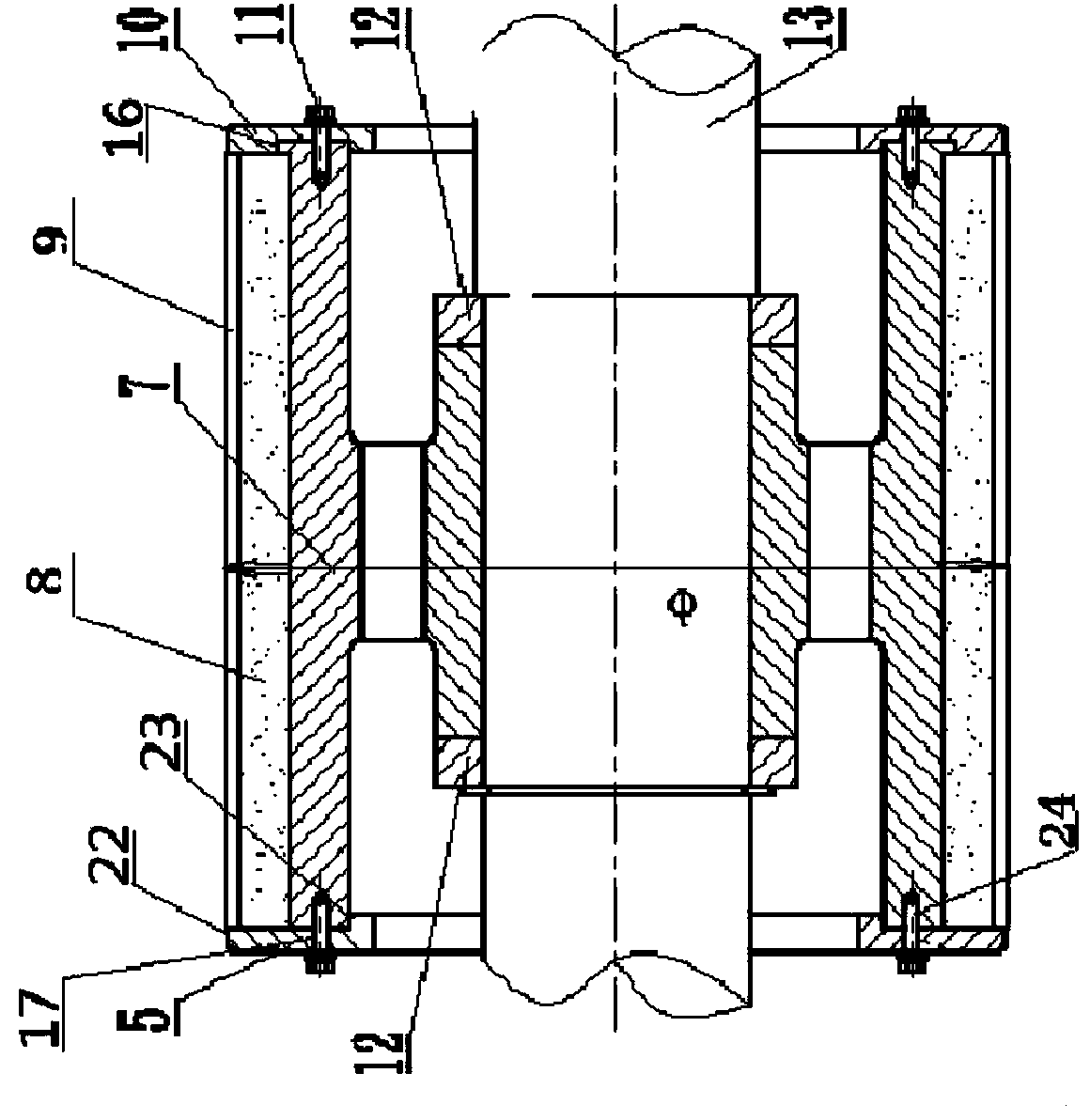

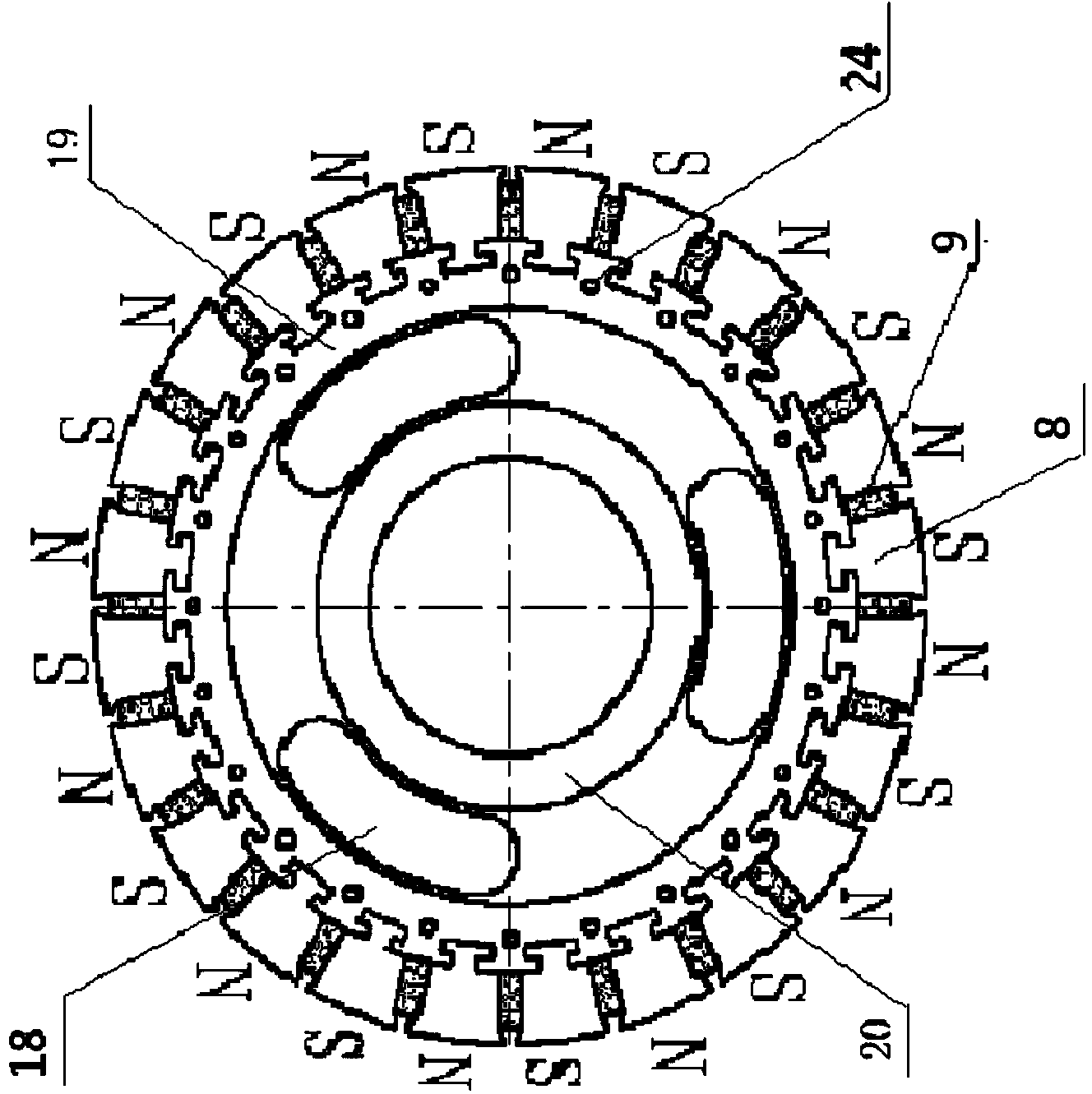

[0011] The embodiment of the present invention is a vertical single-screw oil well pump assembled rotor rare-earth permanent magnet high-efficiency / high-power-density direct-drive torque motor. The composition of this motor comprises machine base 6, the motor stator that is made of stator iron core 2 and armature winding 1, motor rotor, upper end cover 4, upper explosion-proof sealing cover 3, lower explosion-proof end cover flange 14. The motor rotor consists of a hollow shaft 13, a non-magnetic aluminum alloy double-tube rotor bracket 7 composed of a large sleeve and a small tube structure, and a rotor upper end plate 5 and a rotor lower end cast by non-magnetic aluminum alloy materials at both ends of the rotor bracket 7. Plate 10, and 24 magnetically conductive pole pieces 9 and 24 rectangular rare earth permanent magnets 8 that are spaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com