Continuous or instrumented indentation device with convex bearing surface and use thereof, particularly for metal sheet indentation

A measurement and continuous technology, applied in the direction of measuring devices, testing material hardness, analyzing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

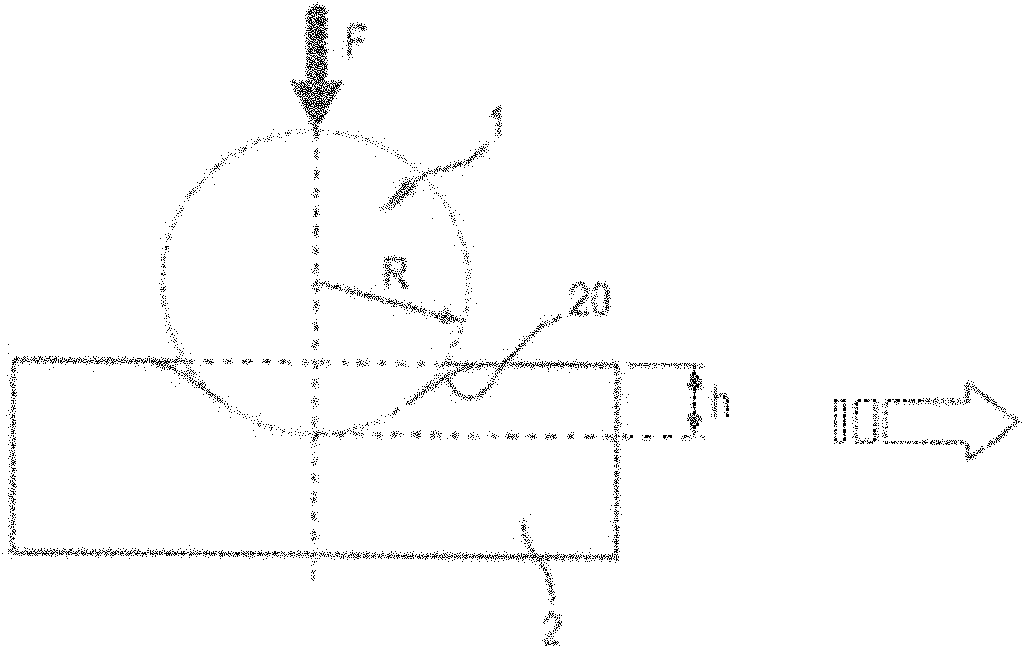

[0074] Let's now refer to Figure 6A , which partially demonstrates the case of a continuous indentation device according to the invention.

[0075] The reason why the installation is only partially displayed is to focus only on the innovative aspects of the installation.

[0076] Among them, we can note that there is an indenter 10 of known type, perpendicular to the XX' axis.

[0077] In order to simplify the drawings, the mechanism that can vertically displace the pressure head from top to bottom or vice versa is not shown here.

[0078] The device is equipped with a platen 40 on which the material to be tested is placed. The platen 40 is placed on the force sensor mechanism 41 which is supported by the frame 4 in the device.

[0079] According to the present invention, on the extension line of the longitudinal axis XX' of the indenter 10, the support for the material 2 to be tested comprises a convex surface on which the material 2 is placed, facing the indenter.

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap