Parallel dislocation type parallel mechanism capable of three-dimensional translational motion and one-dimensional rotation

A staggered and parallel technology, applied in the field of robotics, can solve the problems of large size of the moving platform, poor force transmission effect, unfavorable mechanism efficiency, etc., achieving good rigidity and stability, satisfying complex pick-and-place operations, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

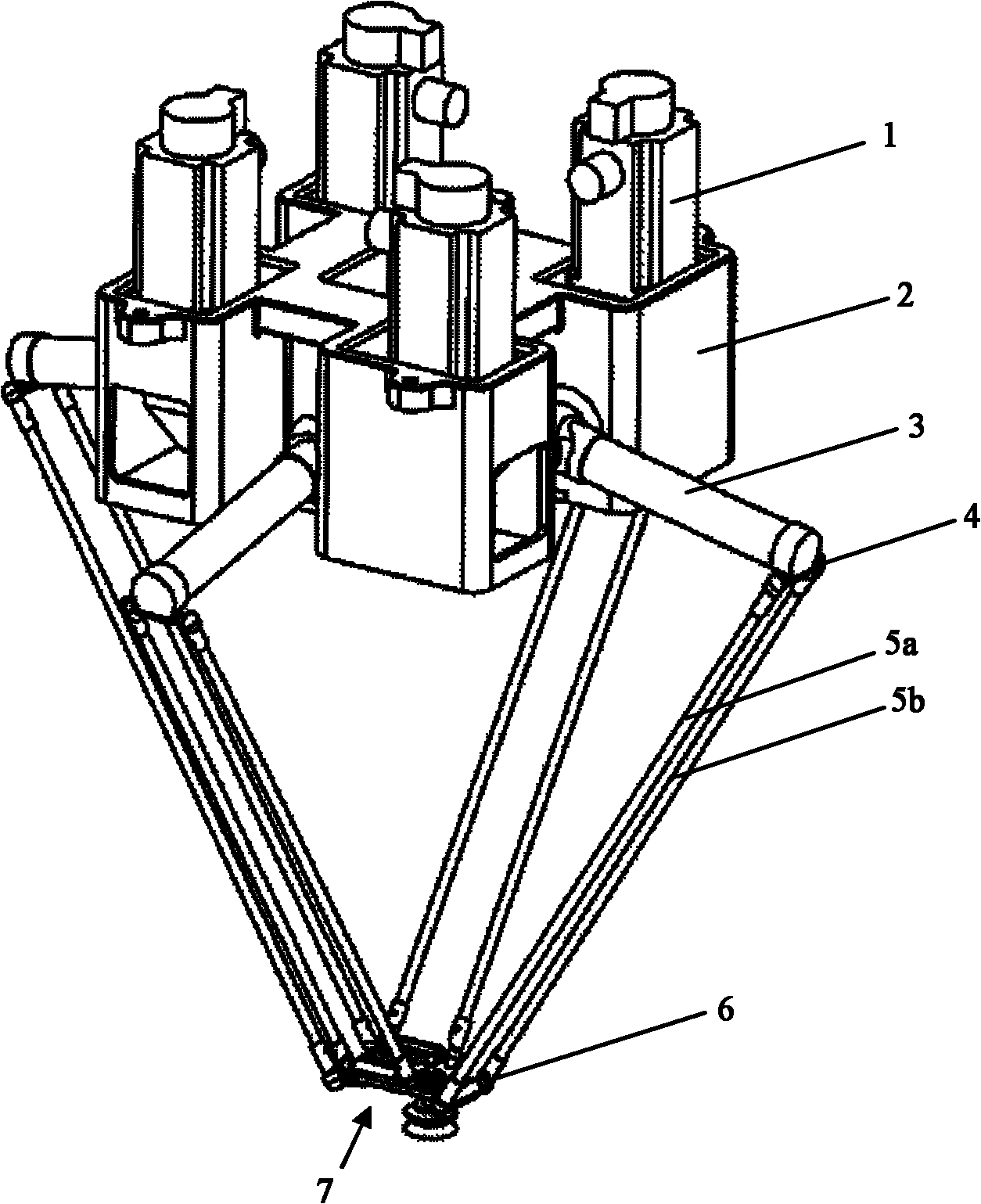

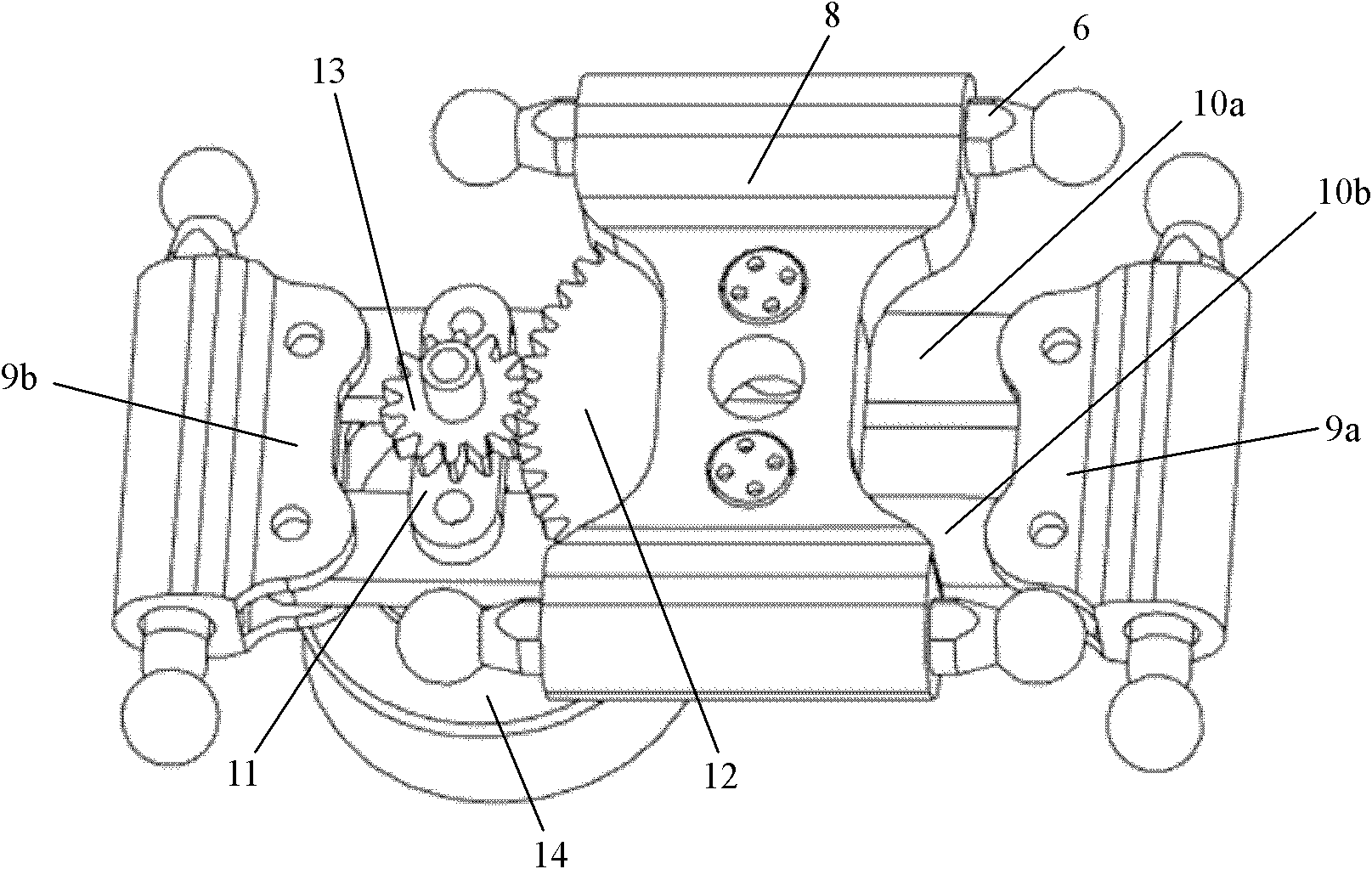

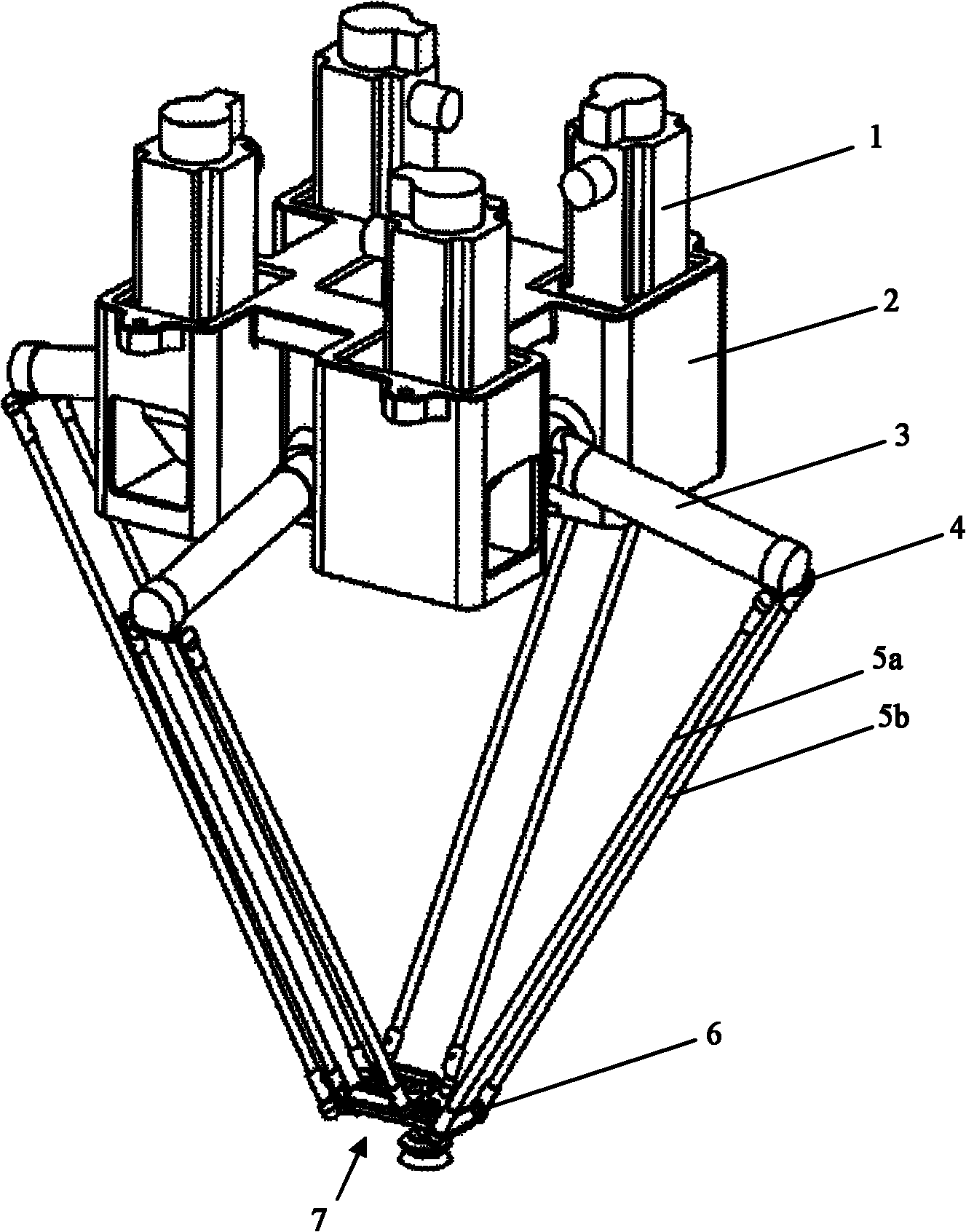

[0011] see figure 1 , a parallel staggered three-level one-rotation parallel mechanism of the present invention, comprising a fixed frame 2, a moving platform 7, and four branch chains with the same structure symmetrically arranged between the fixed frame 2 and the moving platform 7; each branch chain It is composed of a near frame rod 3 , an upper connecting shaft 4 , two mutually parallel and equal-length far frame rods 5 a, 5 b and a lower connecting shaft 6 . One end of the near frame rod 3 is affixed to the output end of the drive device 1 fixed on the fixed frame 2, and the other end of the near frame rod 3 is affixed to the upper connecting shaft 4; one end of the far frame rod 5a, 5b The ball hinges are respectively connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com