Manufacture method for pneumatic tire and rigid core used for the method

A technology of pneumatic tires and rigid cores, applied in the field of rigid cores, can solve the problems of low storage management efficiency, increased storage space, and increased manufacturing costs of core sections c, and achieve the goal of suppressing the reduction in storage management efficiency and facilitating storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Next, embodiments of the present invention will be described in detail.

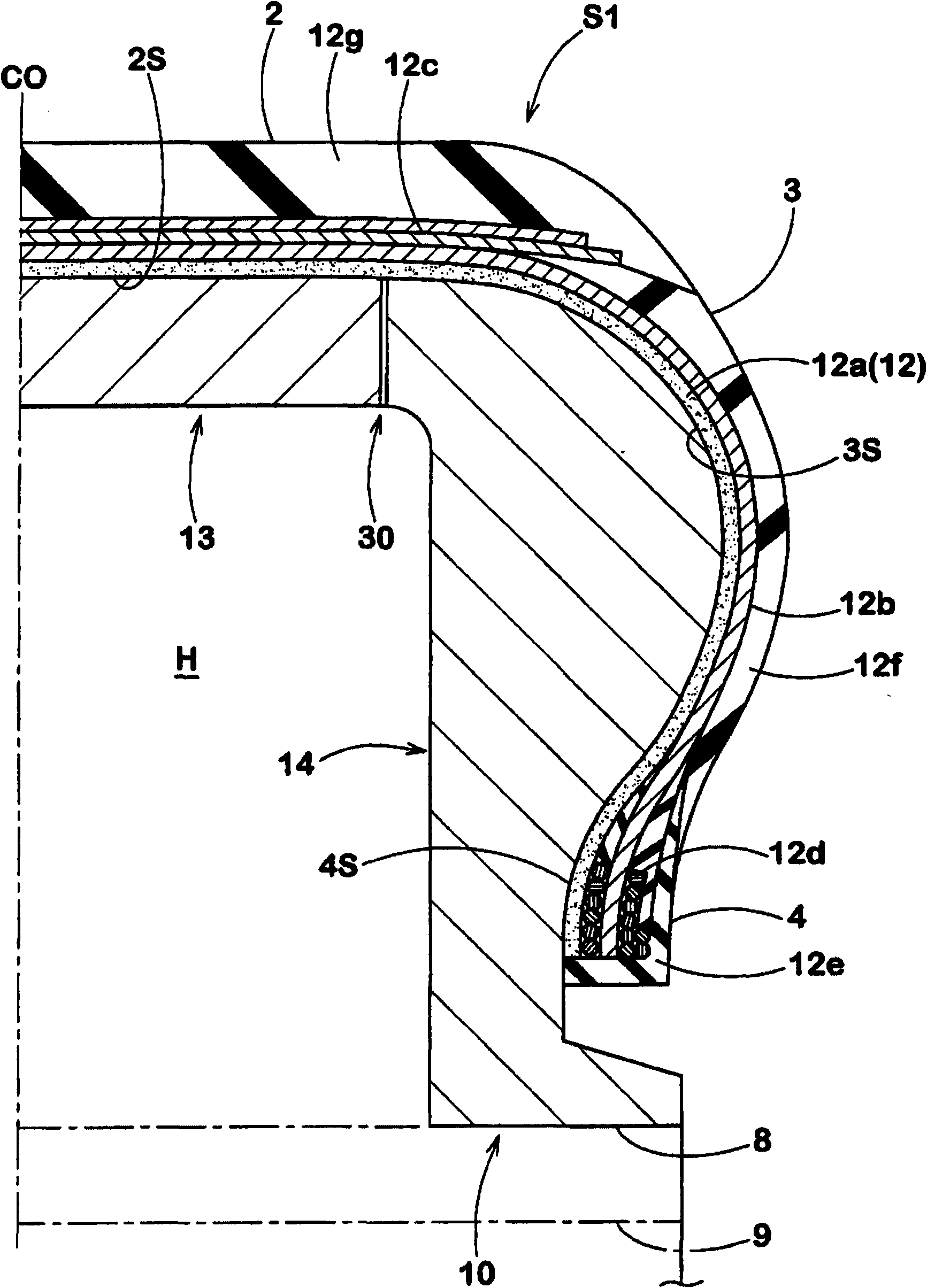

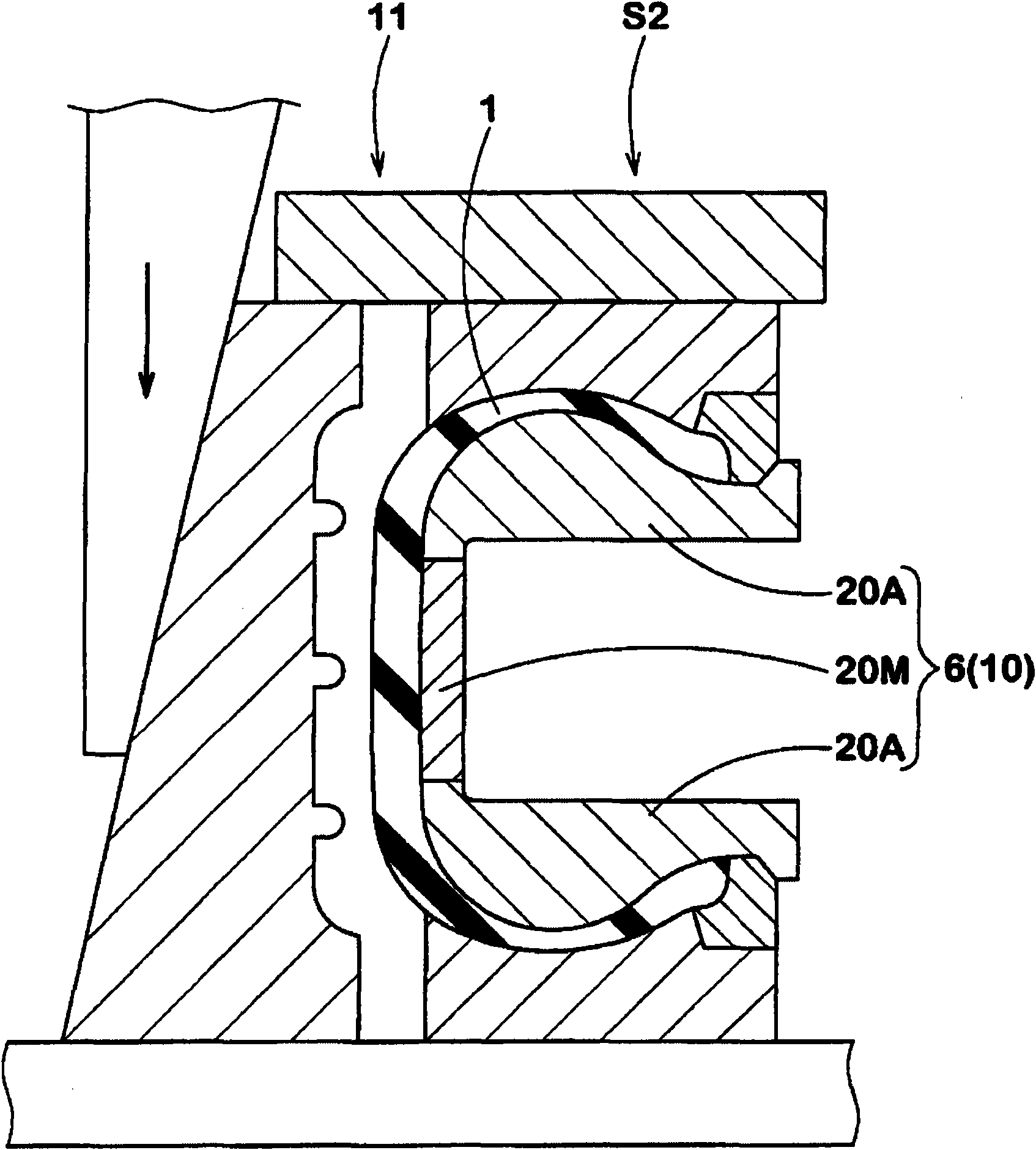

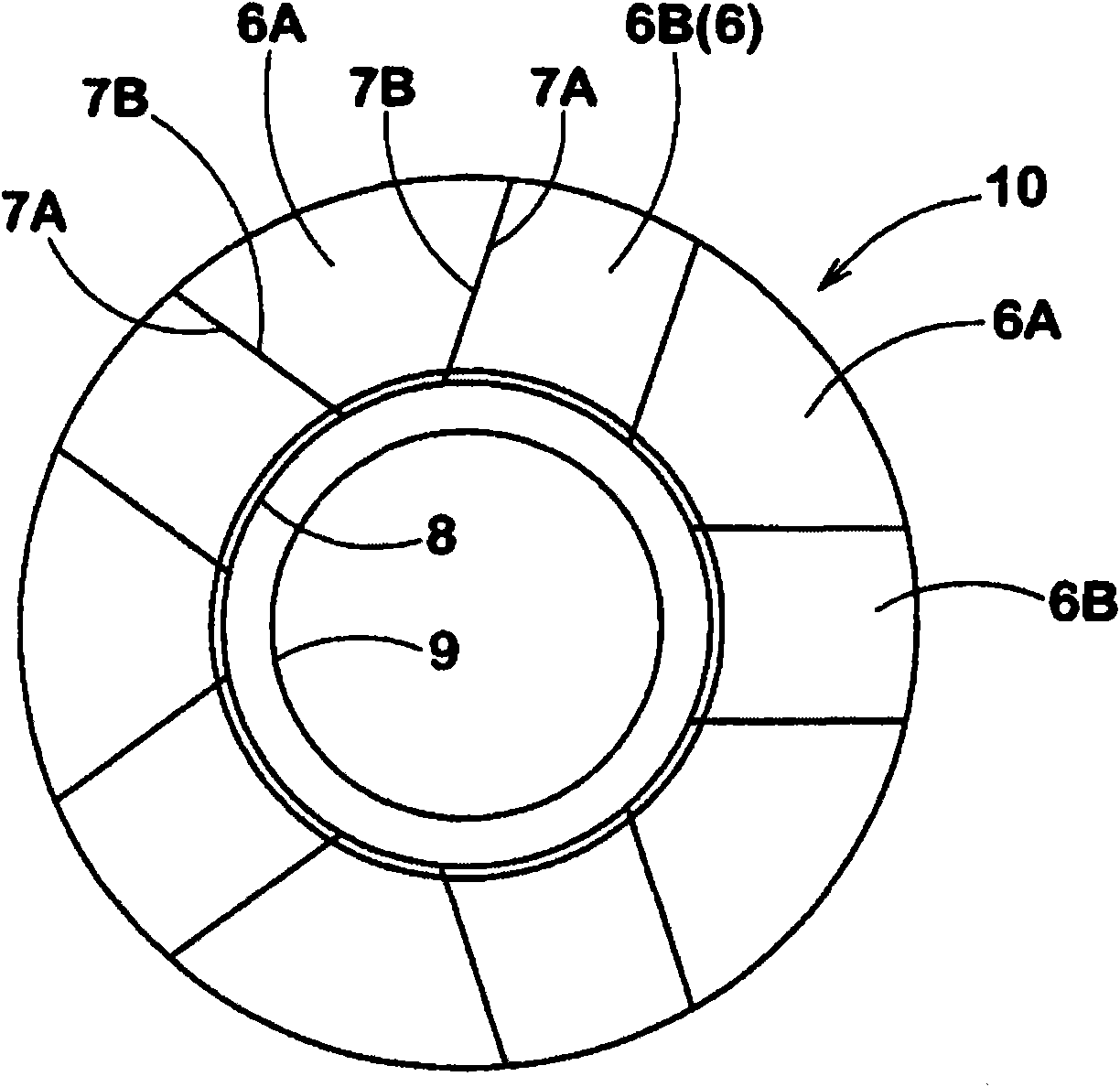

[0077] The manufacturing method of the pneumatic tire of the present invention is constituted to include: a green tire forming step S1, such as figure 1 As schematically shown, this process uses a ring-shaped hollow rigid core 10, and the raw tire 1 is formed by sequentially attaching unvulcanized tire components 12 on the outer surface of the rigid core 10; vulcanization process S2, such as figure 2 As schematically shown, in this process, the raw tire 1 and the rigid core 10 are put into the vulcanization mold 11 for vulcanization molding. Examples of the tire constituent member 12 include an innerliner 12a, a carcass cord 12b, a belt 12c, a bead core 12d, a lap rubber 12e, a sidewall rubber 12f, and a tread rubber 12g.

[0078] In addition, since various conventional green tire forming steps and vulcanizing steps using rigid cores can be appropriately adopted as the raw tire forming step S1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com