Vibration reducing control device

A control device and soil technology, applied in the field of plate compaction, can solve the problems of brittleness, high price, and failure to achieve vibration reduction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

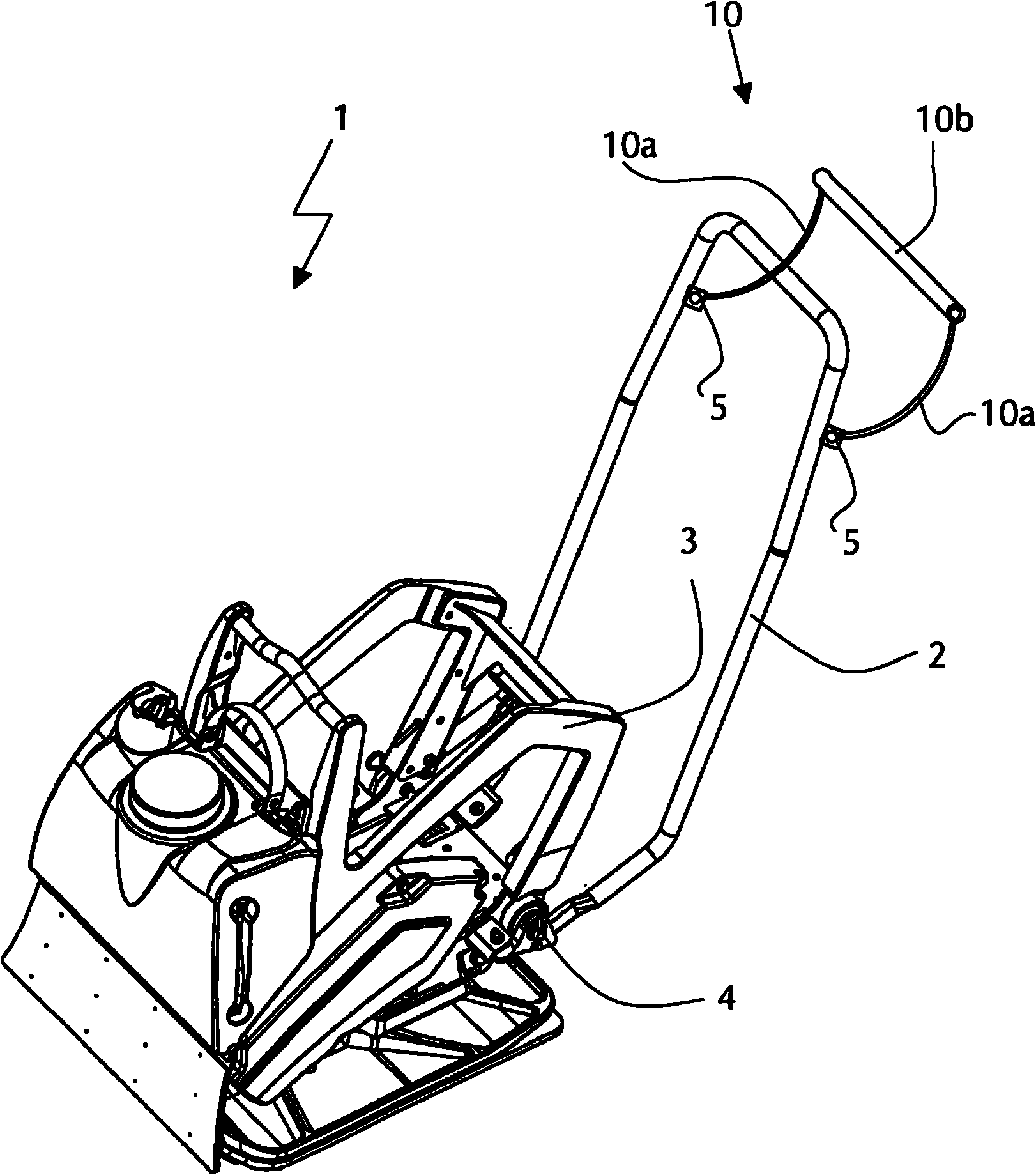

[0048] figure 1 It is a plate compactor 1 with a base 3 . The control armrest frame 2 of the plate compactor 1 is connected with the base 3 at the connection point 4 . For vibration reduction, an elastomer shock absorber (not shown) is installed between the base 3 and the control armrest frame 2 . In principle, the control armrest frame 2 can also be used as the control device of the plate compactor 1, but it cannot effectively reduce the handle transmitted from the vibrator to the control armrest frame 2 (that is, the horizontal connection between the two vertical bars of the control armrest frame 2) Vibration, vibration reduction can not achieve satisfactory results. Therefore, the control device of the present invention is fixedly installed at the connection point 5 .

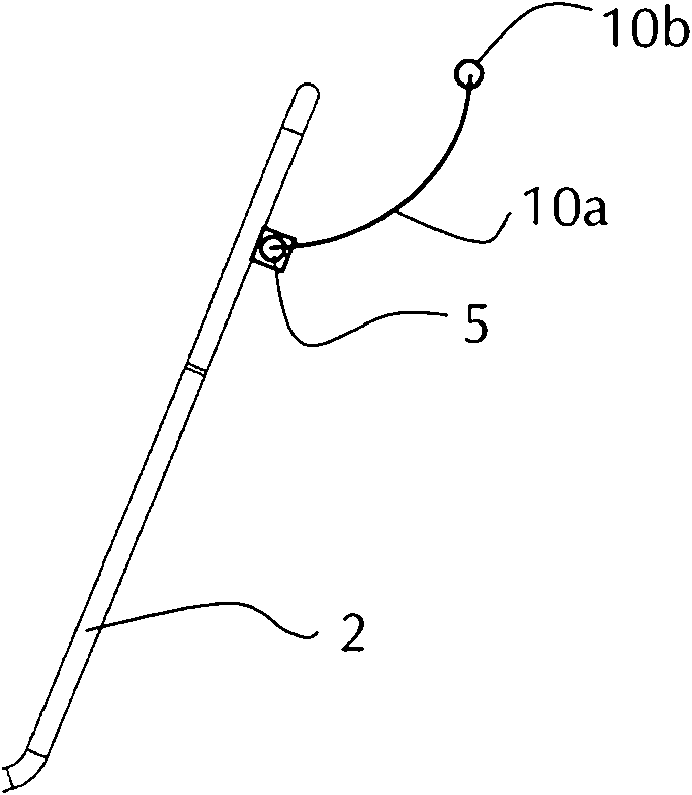

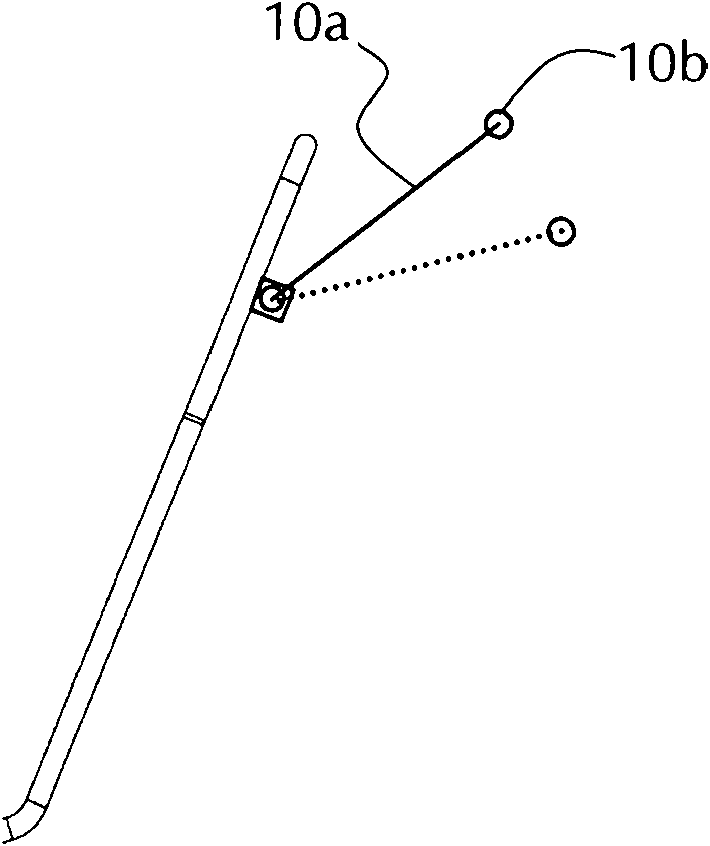

[0049] according to Figure 1 In the example shown, the control device 10 of the present invention includes a plastic handle 10b and two sections of bendable plastic rope 10a. The handle 10b is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com