Method for evaluating minimum area of line profile error of cross section of skirt part of variable-ellipse piston

A cross-section line and minimum area technology, applied in precision metrology and computer application fields, can solve the problems of not guaranteeing the minimum area, not suitable for precision, ultra-precision parts evaluation, evaluation of geometric shape accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

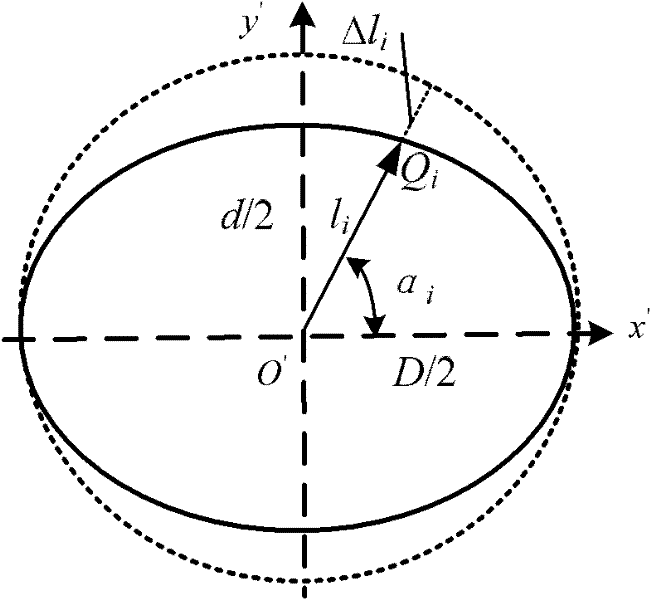

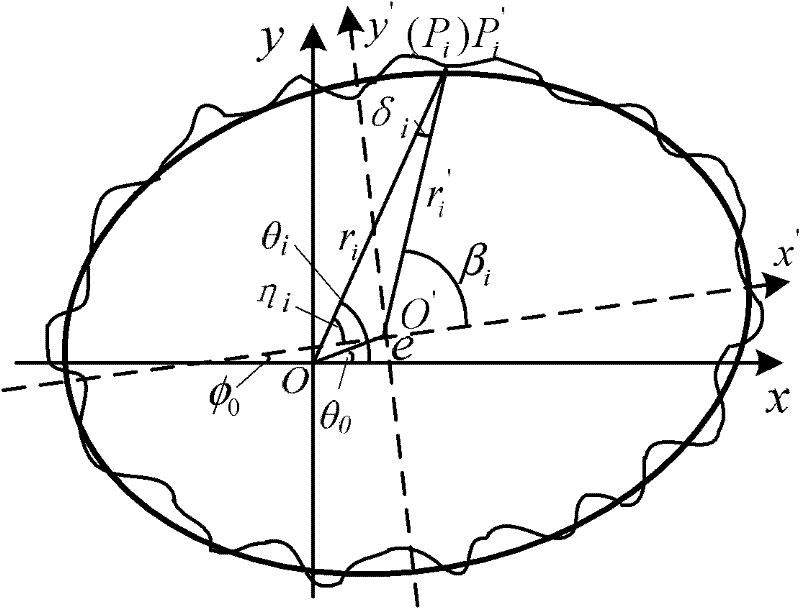

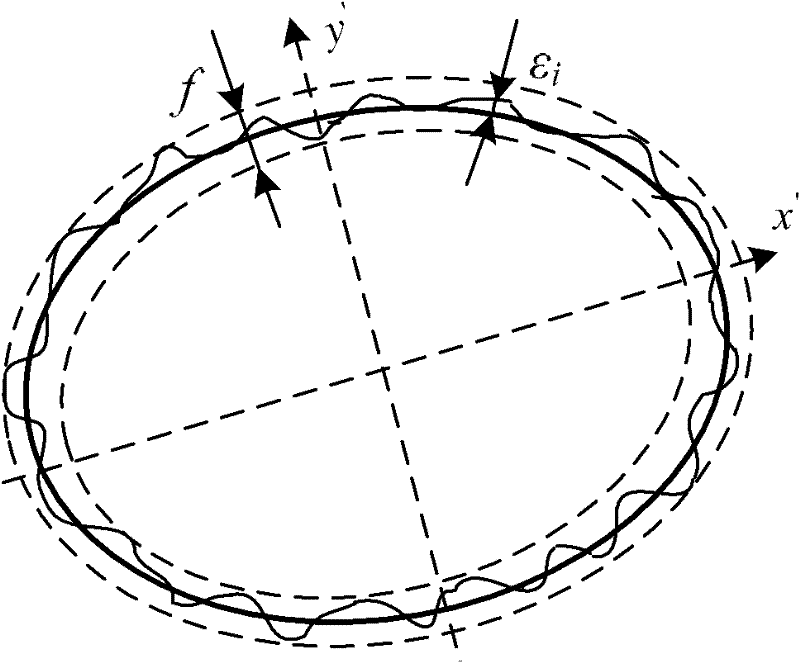

[0038] Step 1. Establish the measurement rectangular coordinate system xoy with the center of rotation o of the measurement platform as the center of the measurement coordinate system xoy, place the cross-sectional line profile of the measured variable ellipse piston skirt in the measurement rectangular coordinate system xoy and the measured variable ellipse piston skirt The angle φ between the major axis of the cross-sectional line profile and the ox axis 0 -10°≤φ 0 ≤10°, measure and obtain the point P on the cross-section line profile of the variable ellipse piston skirt i (x i ,y i ) and the measured point P i (x i ,y i ) coordinates are transformed into polar coordinates P by formula (1) i (r i , θ i ), i=1, 2,..., n, n is the number of measuring points and n is a positive integer, x i and y i are measuring point P i The coordinate value under the measurement Cartesian coordinate system xoy, r i and θ i for measuring point P i Relative to the radius and polar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com