Improved drum and drum hub for a heat exchange brake, particularly for an automobile, and thus-fitted vehicle

A motor vehicle and brake drum technology, applied in the field of vehicles, can solve the problems of poor rigidity, quality and cooling effect, and achieve the effects of reducing quality, balancing processing enhancement, increasing rigidity and heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

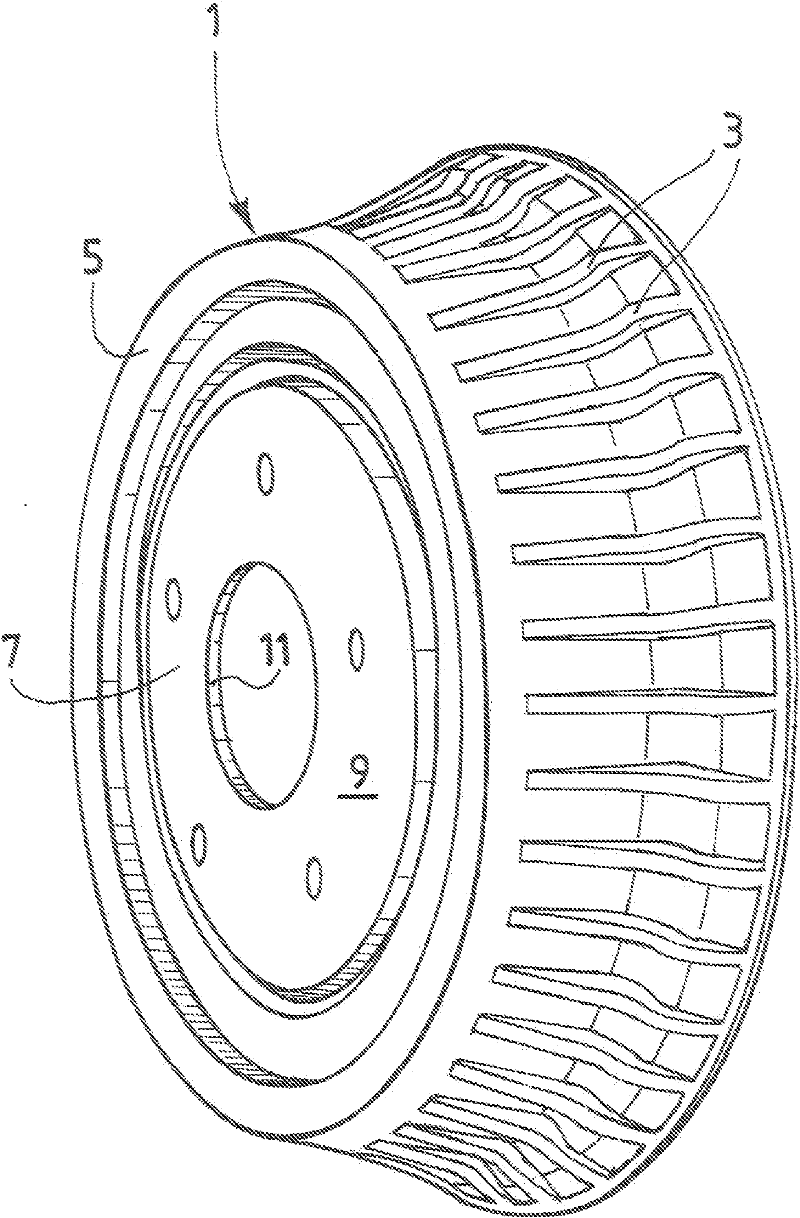

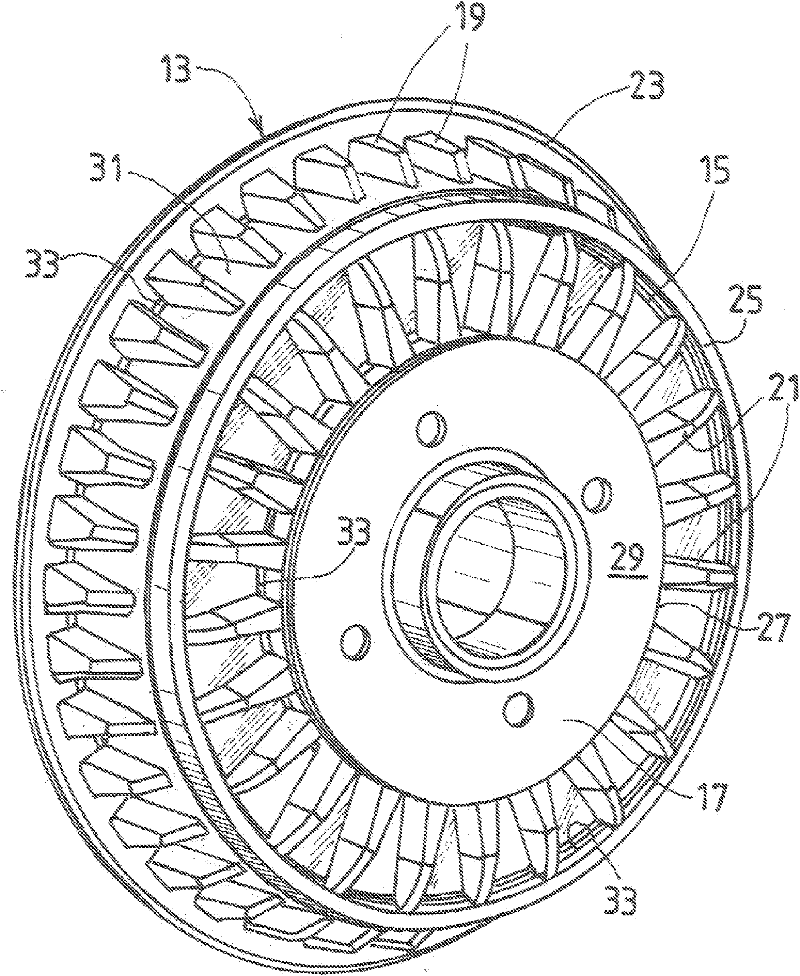

[0022] In FIG. 1 , a known brake drum hub 1 with peripheral ribs 3 is shown. The drum part 5 in the strict sense is incorporated into the hub part 7 of the vehicle and the entire assembly or drum hub 1 is constructed as an axially symmetrical single component. The drum part 5 has a cylindrical detent track (not shown) and an outer peripheral rib 3 extending across its width on the outer periphery opposite the detent track. The hub part 7 is coaxial with the drum part 5 and comprises a disc 9 which receives the axle (not shown) through its central circular opening 11 . In addition to the fact that they increase the rigidity of the drum part 5, the peripheral ribs 3 also contribute to the dissipation of the thermal energy generated during braking of the drum part. However, this energy dissipation can be achieved by, for example, figure 2 The illustrated drum hub 13 according to the invention is reinforced.

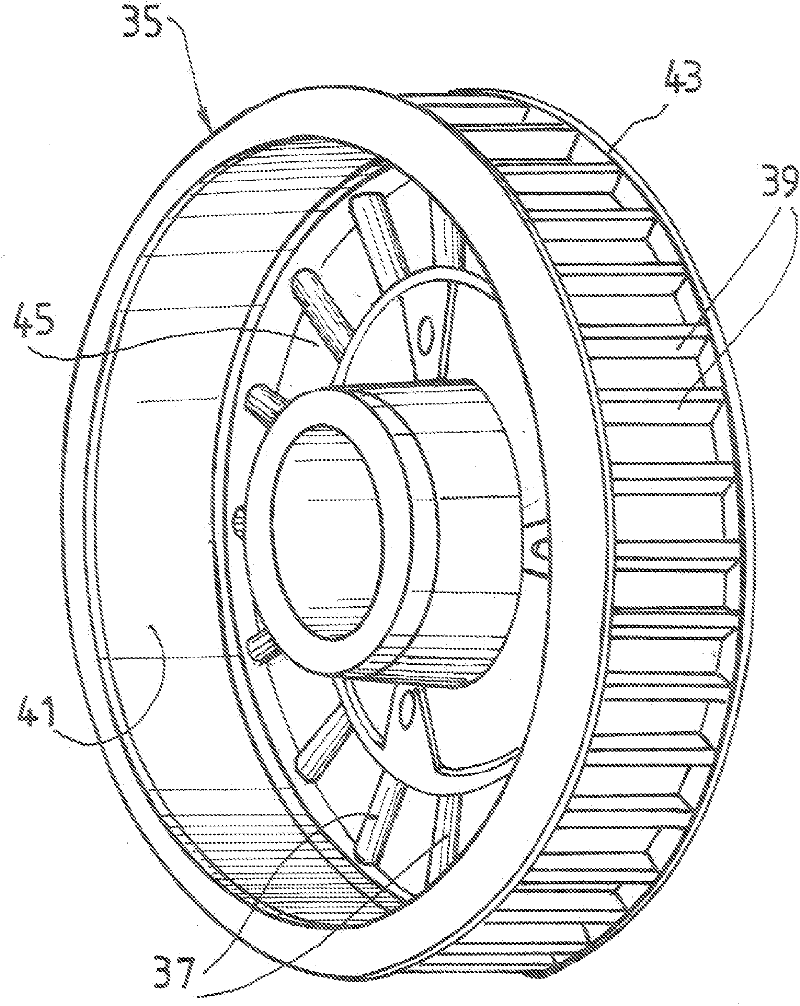

[0023] As shown in FIG. 1 , the drum part 15 is incorporated into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com