Hydraulic low-speed walking transmission system

A transmission system and low-speed technology, applied in the field of transmission system, can solve the problems of damaged diesel engine and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

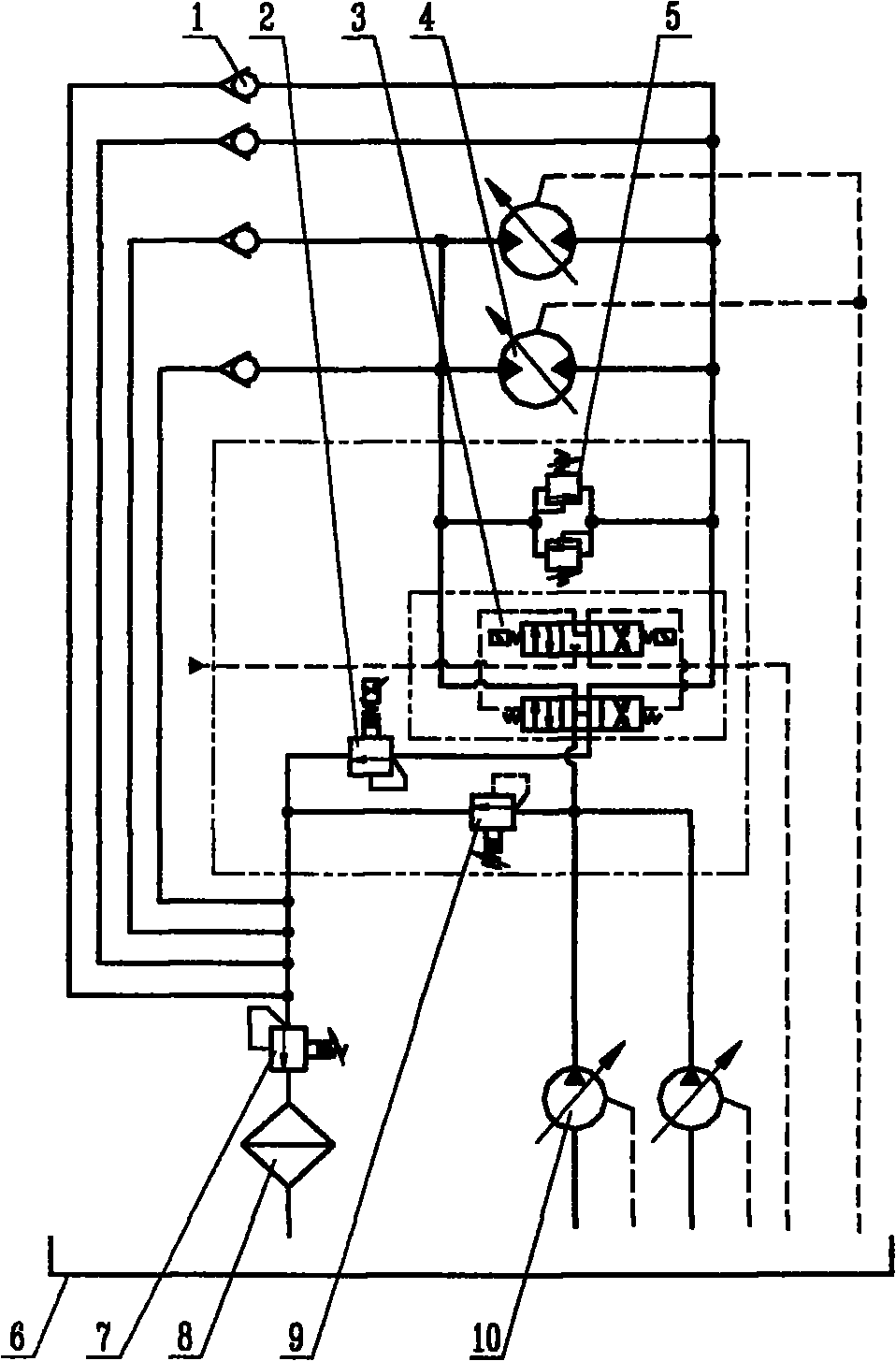

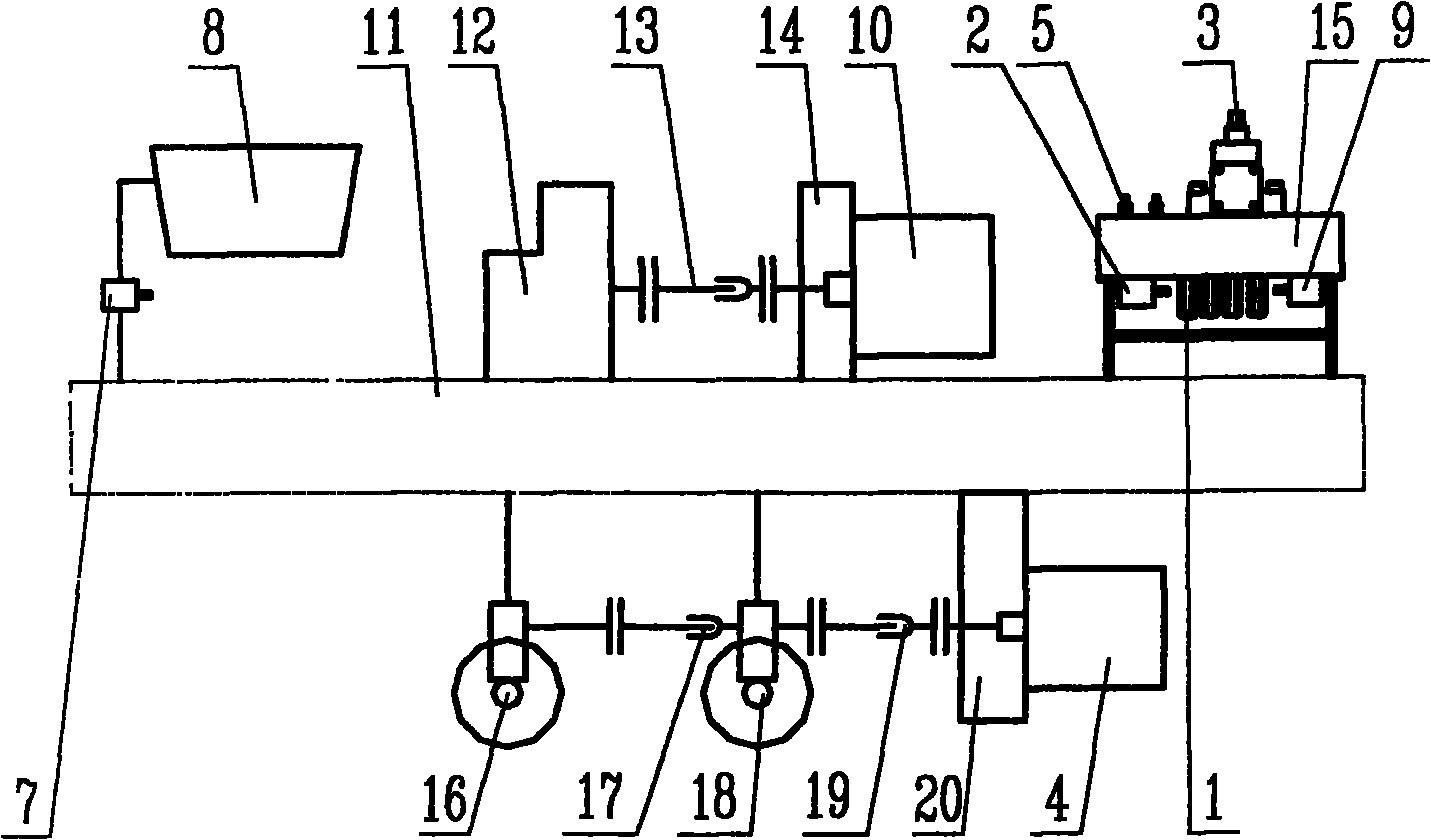

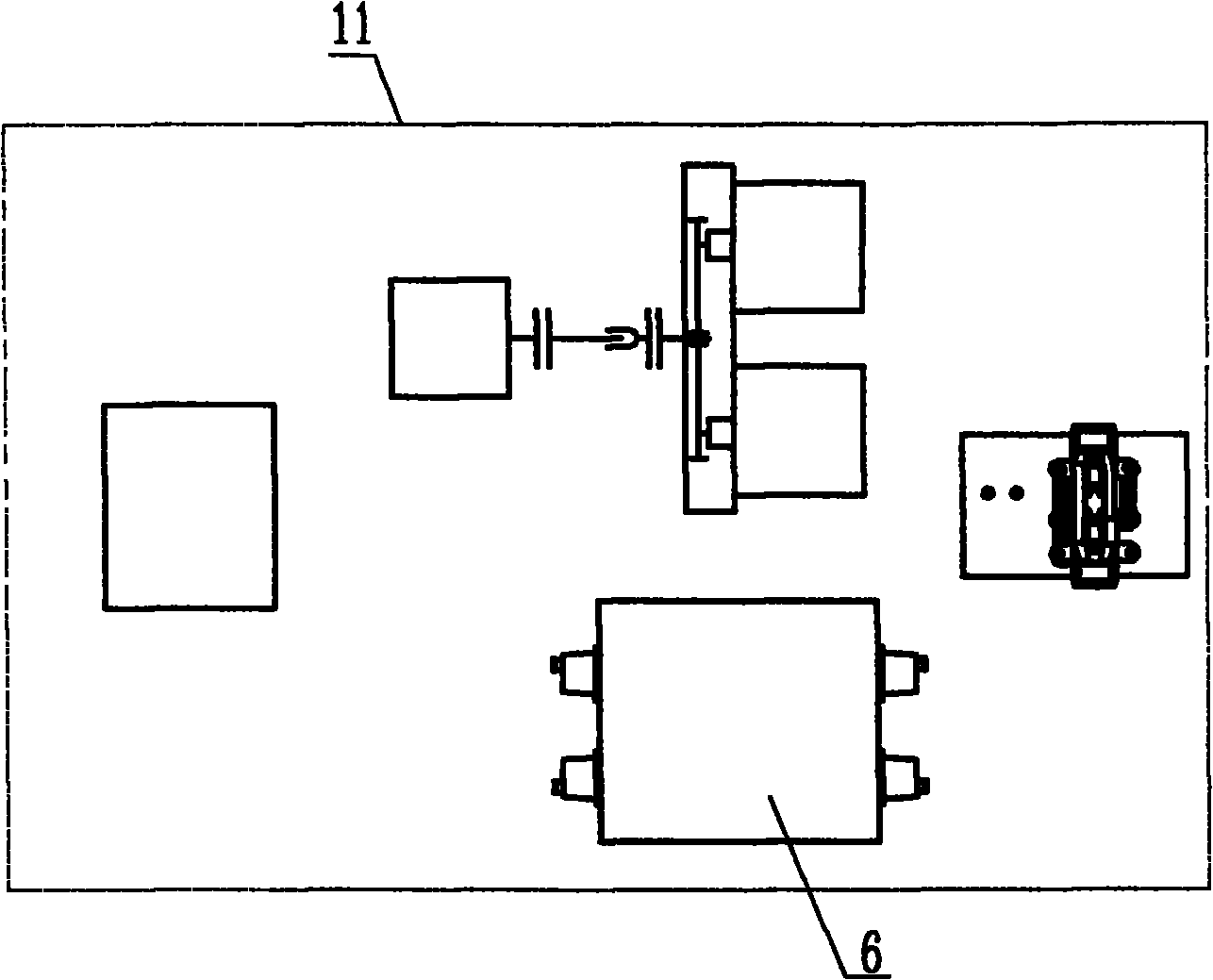

[0014] figure 1 Among them, hydraulic oil pump 10, pilot-operated second relief valve 9 (pilot-operated relief valve), electro-hydraulic reversing valve 3, electric proportional relief valve 2, check valve 1, The hydraulic motor 4, the cooling device 8, the oil tank 6, and the direct-acting third overflow valve 5 that can drive the vehicle to run under the action of pressure oil form an open hydraulic system circuit. The electro-hydraulic reversing valve 3 has two working oil ports, any one of which is used for the high-pressure working oil port, and the other is used for the low-pressure working oil port, the two oil ports of the hydraulic motor, the oil inlet and the electro-hydraulic reversing valve The high-pressure working oil port is connected, and the oil outlet is connected with the low-pressure working oil port of the electro-hydraulic reversing valve. After the two oil pumps 10 merge, they are connected to the inlet P of the electro-hydraulic reversing valve 3 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com