Screw conveyor

A screw conveying device and screw blade technology, applied in packaging and other directions, can solve problems such as material blockage, improve conveying capacity, reduce the number of shutdowns for cleaning, and improve the effect of material blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is used to illustrate the screw conveying device provided by the present invention.

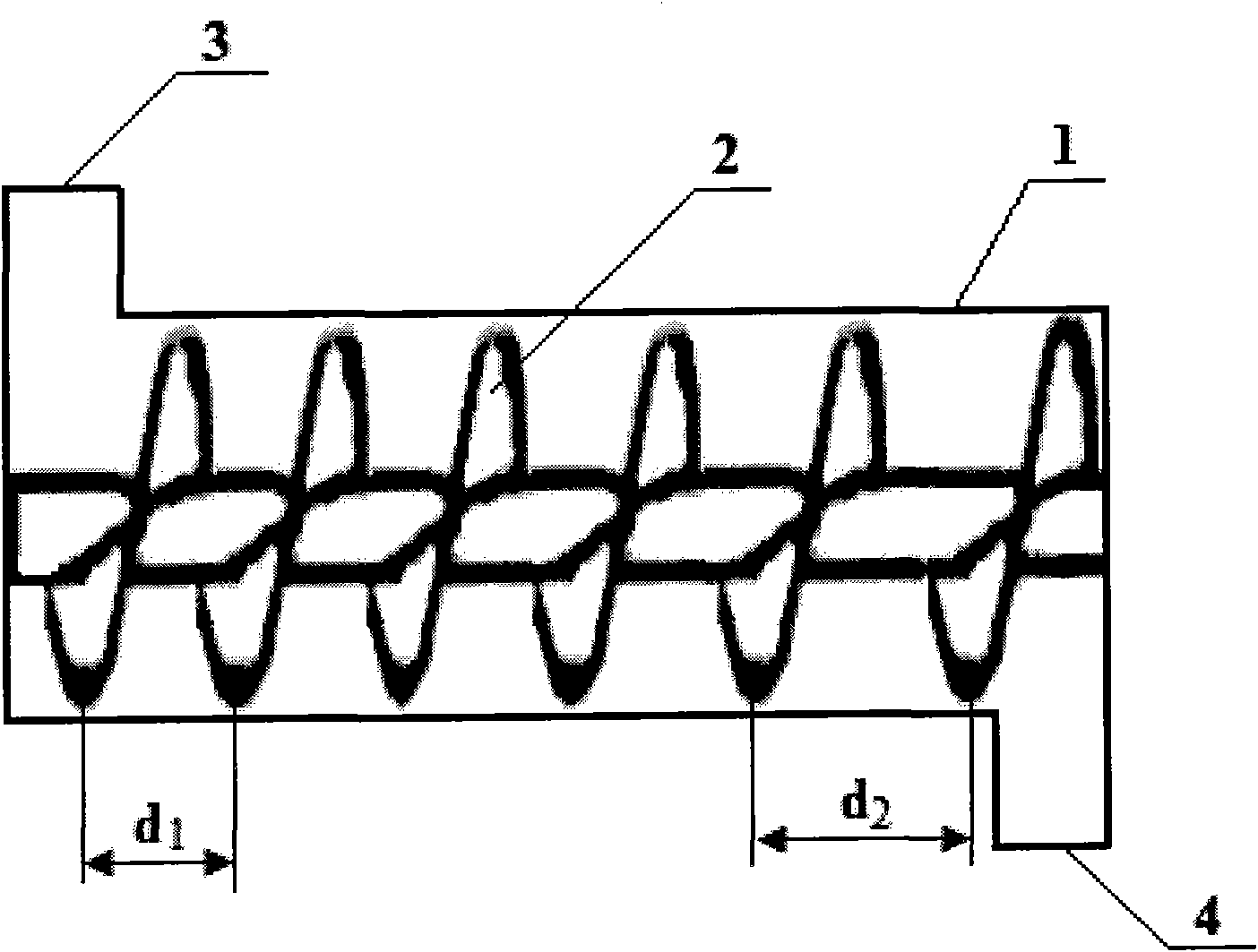

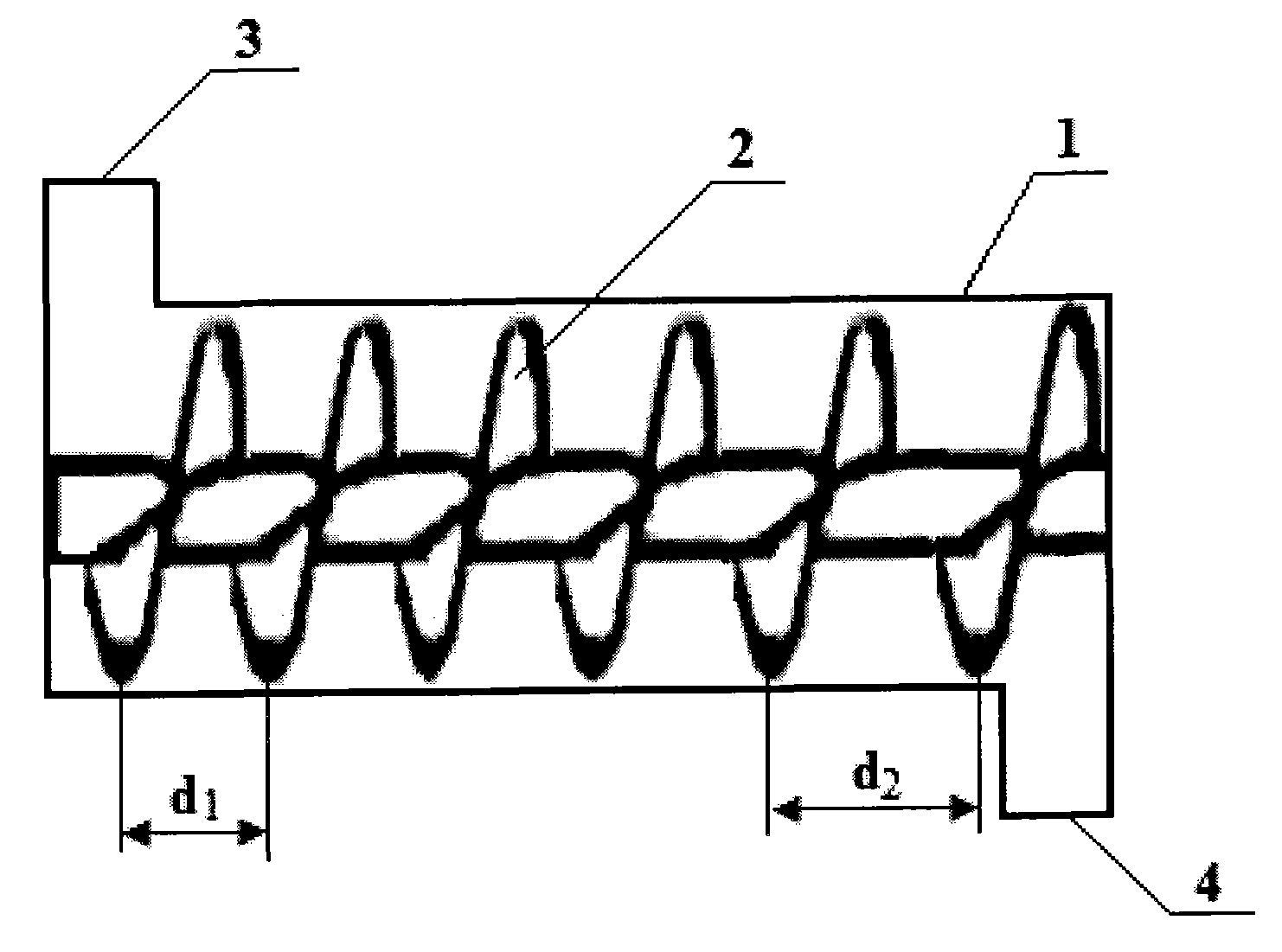

[0027]The LS500 screw conveying device purchased from Botou City Meite Cement Machinery Co., Ltd. is improved. The screw conveying device includes a shell, a screw propeller, a driving device, a feeding port and a discharging port. In the improved screw conveying device, the screw propeller is composed of a central shaft and 7 helical blades, the axial length of the central shaft is 3.07 meters, and the diameter of the outer edge of the screw blades of the screw propeller is both 500 mm, the distance between the outer edge of the screw blade and the casing is 20 mm, along the advancing direction of the material in the screw conveying device, the pitch between the first screw blade and the second screw blade is 400 mm mm, and the pitch between the subsequent helical blades is successively increased by 35 mm.

[0028] Using the above-mentioned improved screw conveying de...

Embodiment 2

[0030] This embodiment is used to illustrate the screw conveying device provided by the present invention.

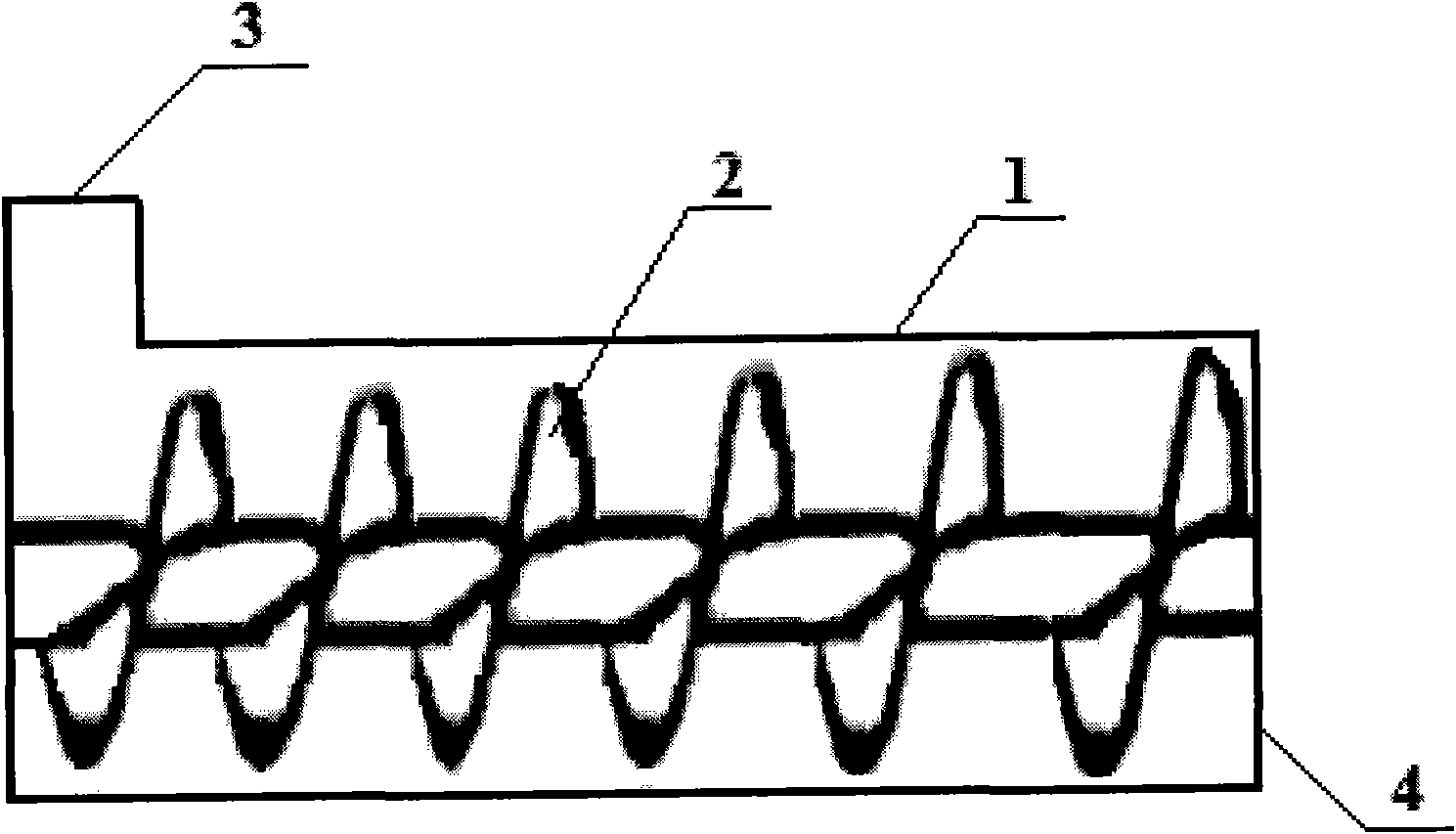

[0031] The LS500 screw conveying device purchased from Botou City Meite Cement Machinery Co., Ltd. is improved. The screw conveying device includes a shell, a screw propeller, a driving device, a feeding port and a discharging port. In the improved screw conveying device, the screw propeller consists of a central shaft and 7 helical blades, the shaft length of the central shaft is 3.07 meters, and the diameter of the inner wall of the casing is 550 mm. In the advancing direction of the screw conveying device, the diameter of the outer edge of the first screw blade is 450 mm, and the diameter of the outer edge of the subsequent screw blades is successively increased by 10 mm; the diameter between the first screw blade and the second screw blade is The pitch between the helical blades is 400 mm, and the pitch between the subsequent helical blades increases by 35 mm.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com