Film stripping and rewinding machine

A rewinding machine and film technology, which is applied in the direction of winding strips, thin material processing, and sending objects, can solve the problems of high cost and low stripping efficiency, and achieve the effect of low cost, high work efficiency, and easy stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in combination with specific embodiments.

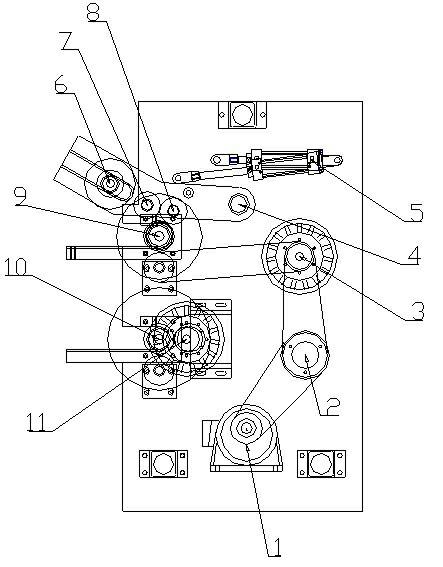

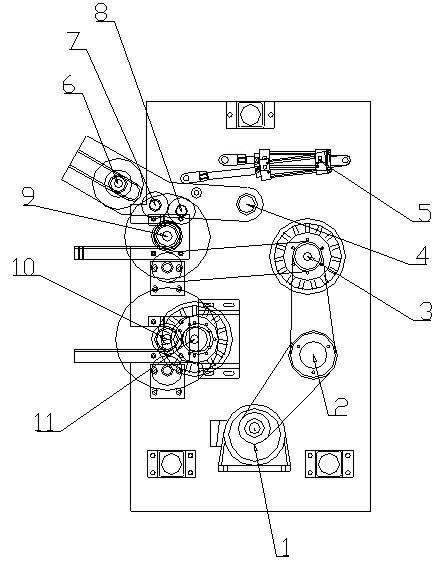

[0011] Referring to the accompanying drawings, the film peeling and rewinding machine of the present invention includes a main motor 1, an intermediate transmission shaft 2, a winding magnetic powder clutch 3, a pressing arm support shaft 4, a pressing cylinder 5, a winding shaft 6, and a cloth guide wheel 7. Rewinding transmission guide wheel 8, rewinding air shaft 9, unwinding air shaft 10 and unwinding magnetic powder brake controller 11, the raw material is packaged on the unwinding air shaft, and the raw material bypasses the rewinding air shaft to the cloth guide wheel and then respectively wound onto the winding shaft and the winding transmission guide wheel; the discharging magnetic powder brake controller is connected with the discharging air expansion shaft for separation and closing control; the main motor is sequentially connected with the intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com