Environment-friendly dual-curing vacuum coating primer special for automobile wheel hub

A dual-curing technology for automobile wheels, which is applied in the direction of epoxy resin coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of uncurable shadow parts and weak metal surface adhesion, and achieve strong adhesion and Good plating performance, good leveling and covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below with specific examples, which are only used for illustration and do not limit the scope of the invention.

[0028] Preparation of primer:

[0029] (1) put reactive diluent, aliphatic epoxy acrylate, aliphatic urethane diacrylate and phenolic epoxy acrylate into the reaction kettle, heat and stir at 45°C for 1 hour to dissolve;

[0030] (2) add the urethane acrylate containing isocyanate group and the photoinitiator to the reactor again, and stir for 0.5h;

[0031] (3) Finally, add the auxiliary agent into the reaction kettle, stir at a high speed for 0.5h, filter with a 500-mesh filter cloth, and finally pack it in a barrel.

[0032] The following examples were prepared as described above.

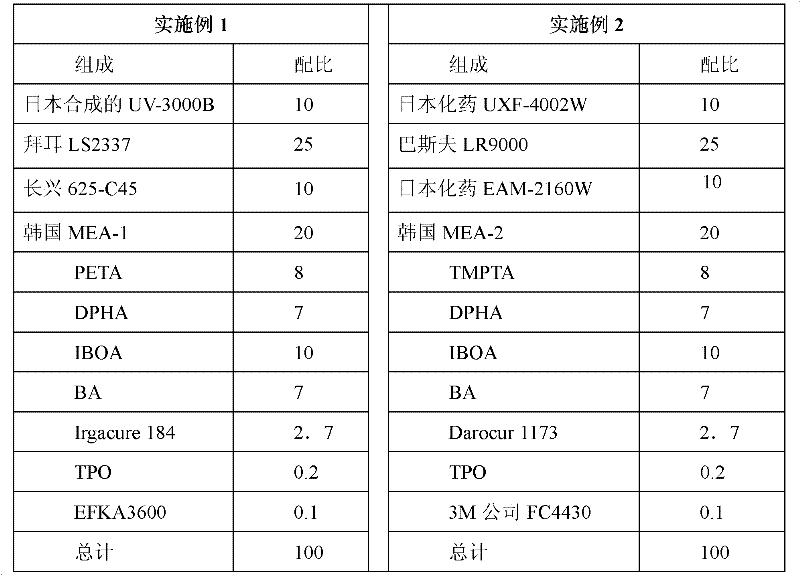

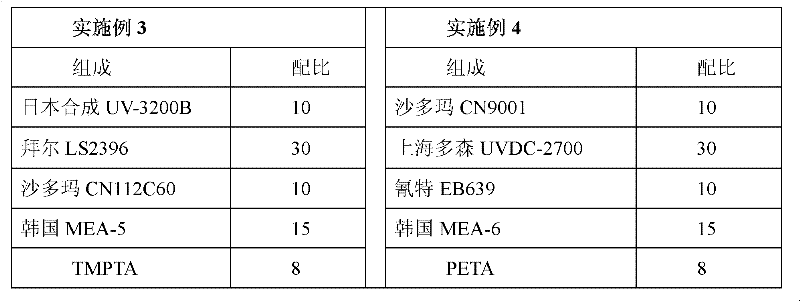

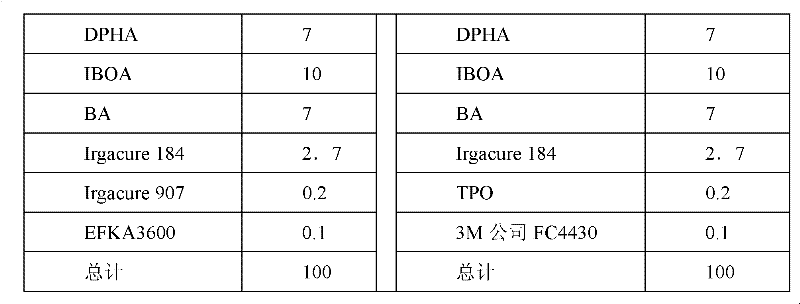

[0033] Recipe for primer:

[0034] Each embodiment is prepared according to the mass ratio in Table 1 and Table 2, and the special dual-curing vacuum coating primer of the present invention is prepared for the environment-friendly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com