Composite edible salt anti-caking agent and preparation method thereof

An anti-caking agent and edible salt technology, applied in the field of food additives, can solve problems such as psychological panic, and achieve the effect of lasting anti-caking effect, strengthening anti-caking effect and increasing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

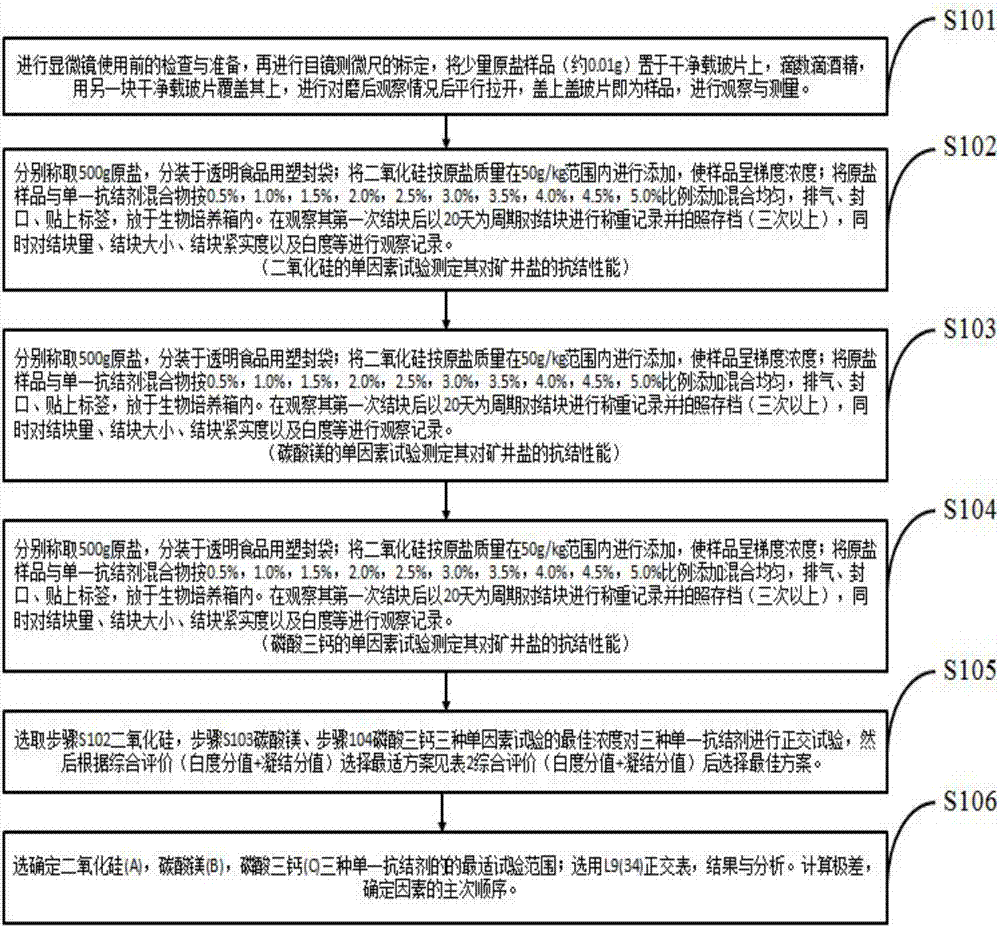

[0018] The preparation method of the composite edible salt anticaking agent provided by the embodiment of the present invention comprises the following steps:

[0019] Step 1. Measuring the particle size of edible salt respectively by microscope method: after the eyepiece micrometer is calibrated, measure the original salt slide of the prepared sample with a microscope respectively, and calculate the particle size;

[0020] Step 2. Selection of an anticaking agent that matches the particle size of table salt. The whiteness is close to that of table salt, and the particle size is close to that of salt crystals. Therefore, silicon dioxide, magnesium carbonate, and tricalcium phosphate with a particle size of 0.01-3.00 mesh are selected as the compound Type edible salt anticaking agent component;

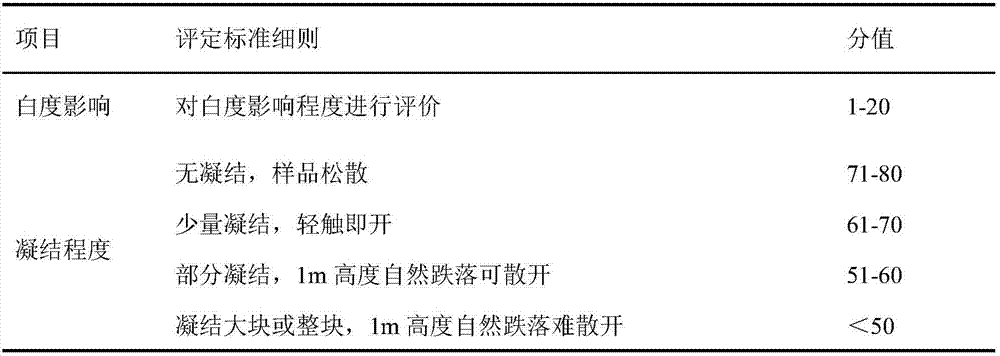

[0021] Step 3. Single factor test: take 500g of raw salt as the unit sample, add the three anti-caking agents in equal gradients within the maximum usage range, mix evenly, pack the ba...

Embodiment 1

[0025] Embodiment 1: Microscopic measurement, well salt salt crystal grain size.

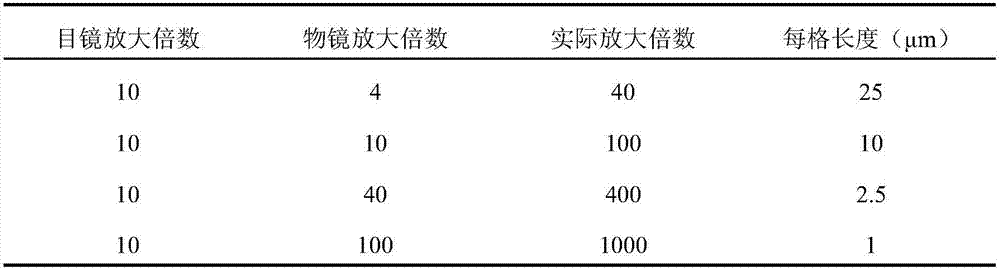

[0026]The first step: inspection and preparation before using the microscope. Put the eyepiece micrometer into the selected eyepiece, install the eyepiece and objective lens on the microscope, put the standard micrometer (10 μm per grid) on the stage, and adjust the focal length by rotating the public drop screw to calibrate the eyepiece micrometer The length represented by one grid ratio (μm);

[0027] Step 2: Calibration of the eyepiece micrometer. First observe with a low power lens, align the focal length, see the scale of the objective lens micrometer clearly, then turn the eyepiece so that the scale of the eyepiece micrometer is parallel to the scale of the objective lens micrometer, and coincide with the first line on the left side of two feet, Then look for another coincidence line two feet to the right, and record the number of divisions of the eyepiece micrometer and the number of di...

Embodiment 2

[0033] Example 2: Single factor test of silicon dioxide Determination of its anti-caking performance to mine salt.

[0034] Step 1: Weigh 500g of raw salt one by one with an electronic balance, and pack them in transparent food plastic bags;

[0035] The second step: use an analytical balance to add silicon dioxide according to the mass of the original salt within the maximum usage range of 50g / kg, so that the sample has a gradient concentration;

[0036] The third step: Add the original salt sample and the single anticaking agent mixture according to the ratio of 0.5%, 1.0%, 1.5%, 2.0%, 2.5%, 3.0%, 3.5%, 4.0%, 4.5%, 5.0%, and mix evenly, exhaust Finally, the plastic bag is sealed and labeled, and placed in a biological incubator (simulated environment, but the humidity is greater than the ambient humidity) with temperature, humidity and pressure stable at room temperature and local atmospheric pressure conditions;

[0037] Step 4: After observing the first agglomeration, wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com