Rapid temperature variation testing machine

A temperature change, testing machine technology, applied in laboratory utensils, chemical instruments and methods, heating or cooling equipment, etc., can solve the problems of uneven air flow, unevenness, influence, etc., to achieve the effect of balanced flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

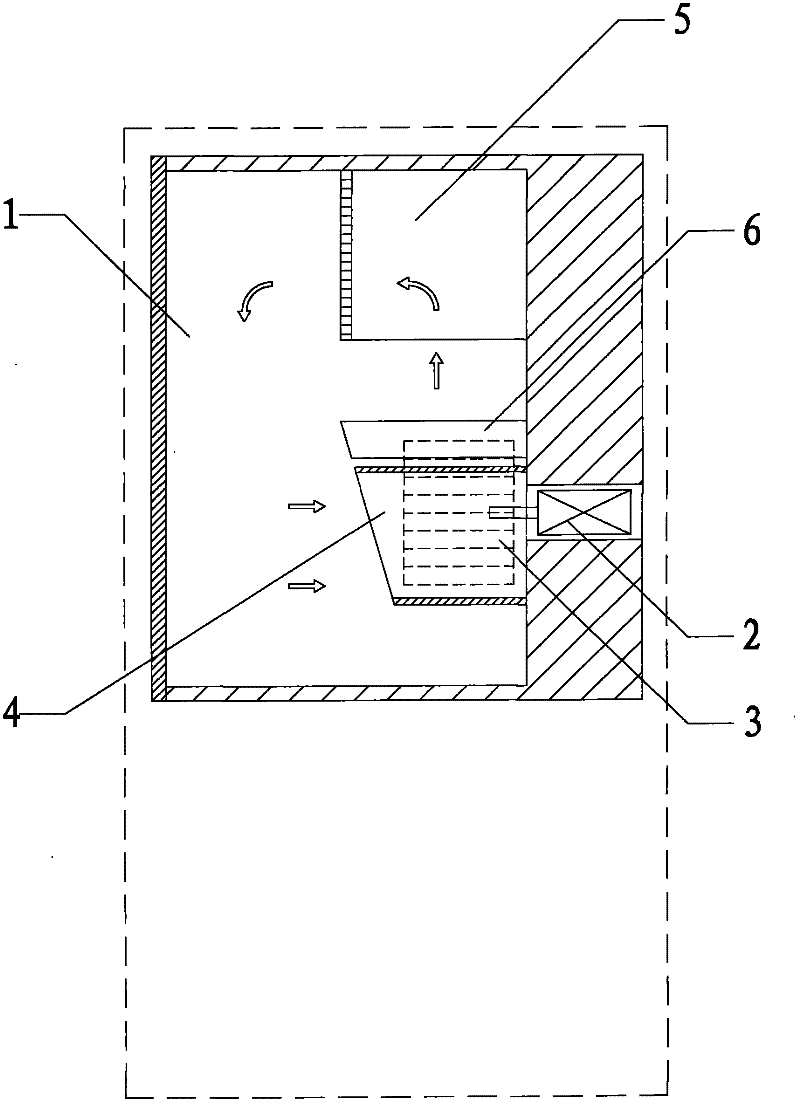

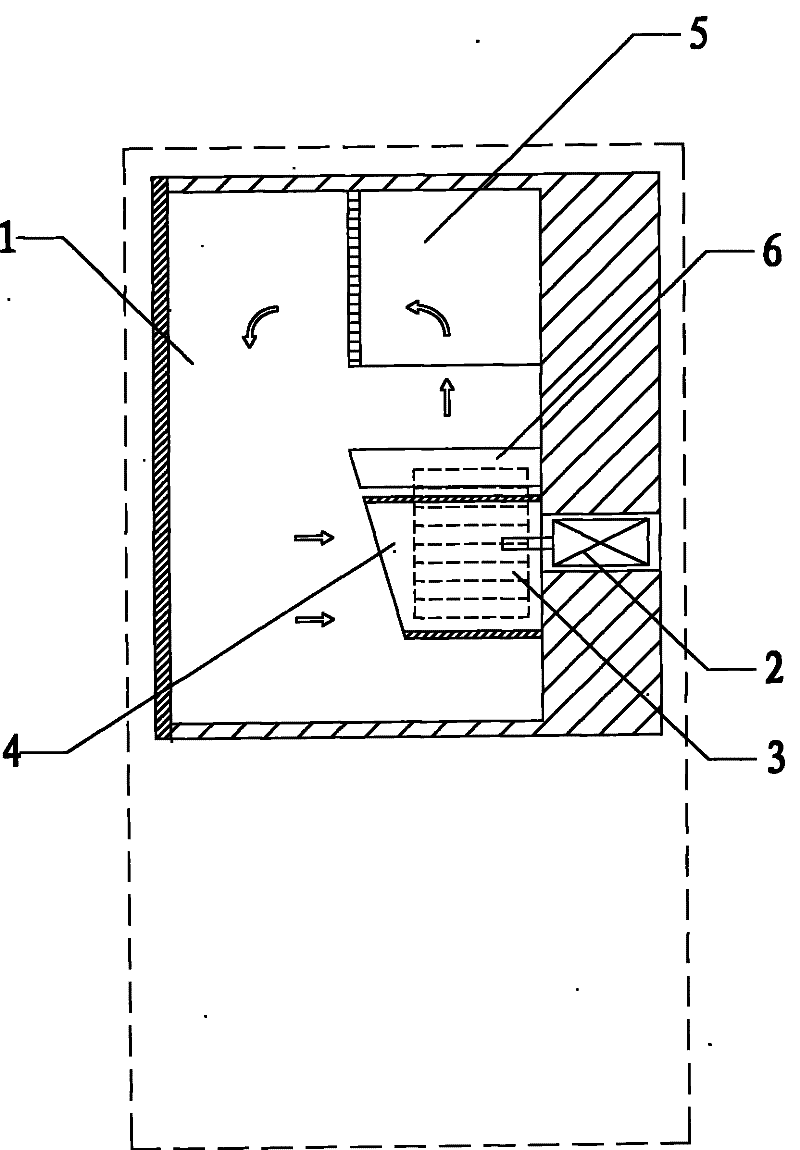

[0011] refer to figure 1 As shown, the rapid temperature change testing machine includes a body and an experimental area 1 located in the body. A motor 2 is arranged on the wall of the experimental area 1. A fan 3 is connected to the motor 2. A cover 4 is arranged outside the fan 3. The cover 4 The upper side is provided with a convection area 5, the convection area 5 is provided with a grid, and the cover body 4 is provided with an air groove, and an air deflector 6 is arranged above the air groove, and the air deflector 6 has two pieces, interlaced with each other It is provided that the cross section of the wind deflector 6 is arc-shaped.

[0012] When the motor 2 drives the fan 3 to rotate, the air circulates in the experimental area 1, and after being sucked into the cover 4, it is discharged from the gap between the two walls of the air deflector 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com