Method for measuring two-dimensional partial micro-defect group damage of toughed material

A technology of ductile materials and measurement methods, which is applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve problems such as incorrect calculation parameters of ductile materials, and achieve overcoming configuration dependencies and measuring high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

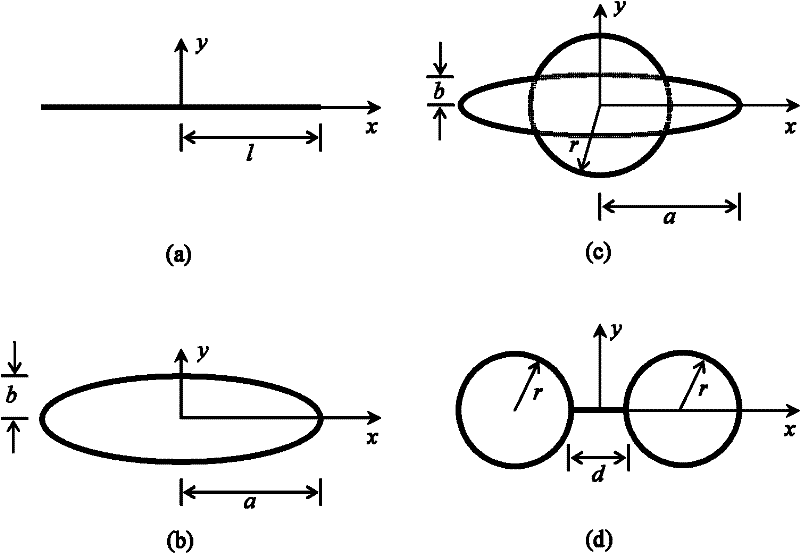

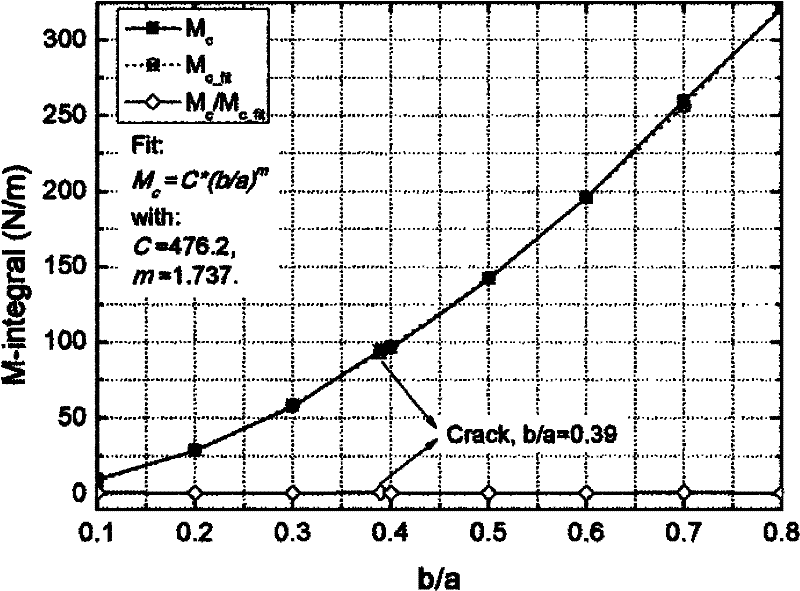

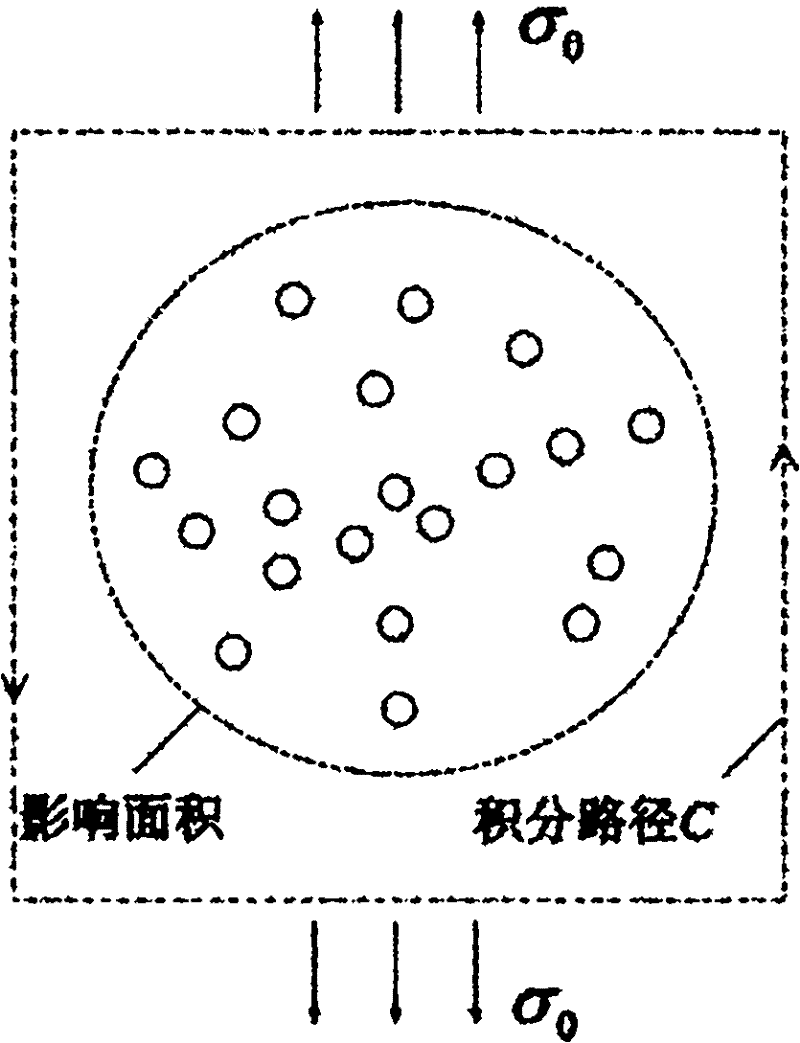

[0034] A method for measuring the damage of two-dimensional local micro-defect groups in ductile materials, comprising the following steps: (1) known elastic modulus E and yield stress σ of ductile materials (such as aluminum alloys, nickel alloys, stainless steel, etc.) Y , strength limit σ b >σ Y , power hardening exponent n>1, power hardening coefficient and fracture toughness K IC . Such as figure 1 As shown, the single hole with radius R in the planar plate of ductile material is calculated by finite element ( figure 1 b), a single elliptical hole (the long axis is a, the short axis is b; respectively take b / a=0.8, 0.7, 0.6, 0.5, 0.4, 0.3, 0.2, 0.1) and a single centrosymmetric crack with a half-crack length of a ( figure 1 a, take the radius of the hole equal to the half-crack length, R=a) respectively reach the critical state under the tensile load in the vertical direction (that is, the boundary material of the circular hole or the elliptical hole has been subject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com