A power supply system and method for controlling a mechanically commutated electric motor

A technology of mechanical commutation and power supply system, which is applied in the direction of control system, AC motor control, excitation or armature current control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

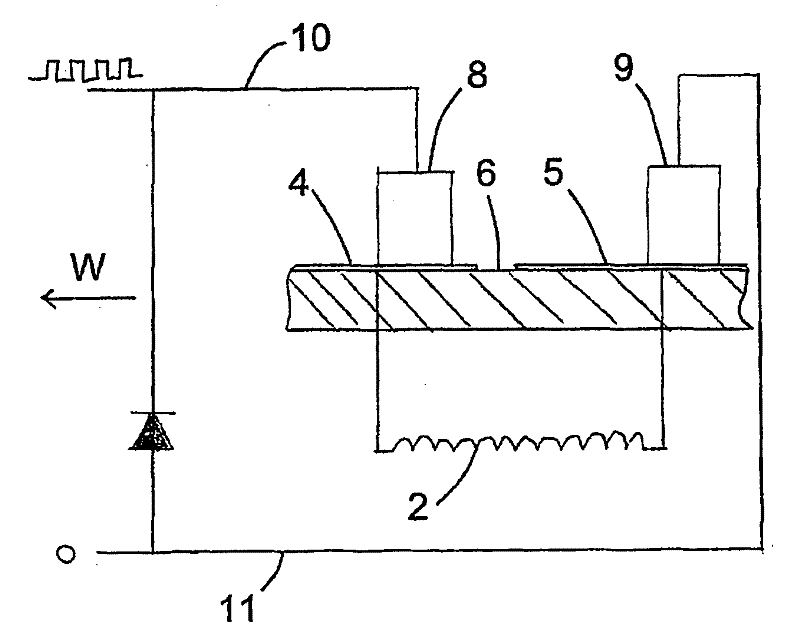

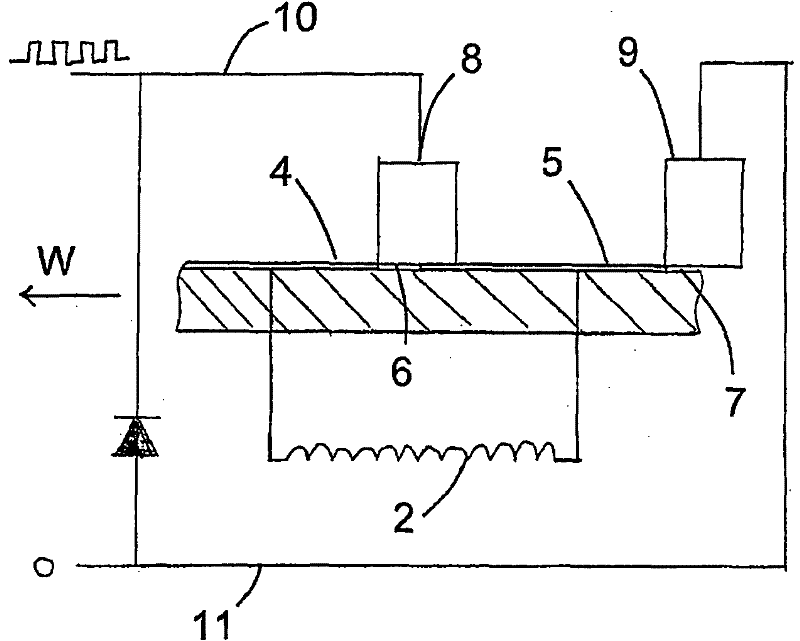

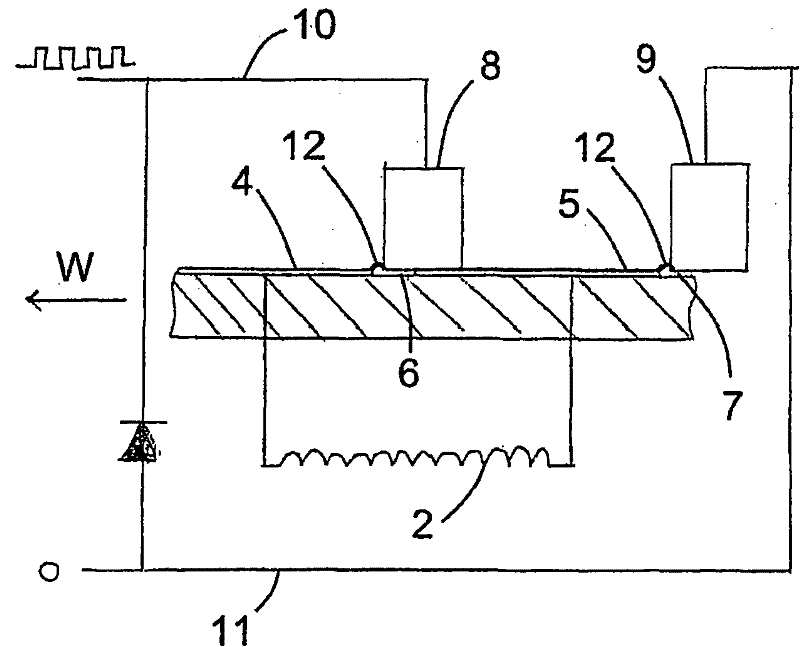

[0037] figure 1 drawn in image 3 and 4A very simplified diagram of the commutator equipment used in a mechanically commutated motor 1. A commutator is a rotary switch that changes the polarity of the current supplied to the magnetizing winding 2 of the electromagnet and thus the polarity of the electromagnet. Because the commutator rotates, it is usually cylindrical, but for illustration purposes it is drawn here as a straight line. The schematically drawn commutator includes a substrate 3 that rotates with the motor rotor in the direction indicated by arrow W. A plurality of contact pads 4, 5 separated by gaps 6, 7 are positioned on the substrate surface. For illustration purposes only two contact pads 4, 5 are drawn. The contact pads 4,5 are engaged by two brushes 8,9 so that current flows to the contact pads 4 via the brushes 8 from a power source (not shown) connected to the current supply lead 10. Current flows from contact pad 4 through magnetizing winding 2 to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com