UAV tour inspection system and implementation method for electrical equipment of photovoltaic power station

A photovoltaic power station and electrical equipment technology, applied in control/regulation systems, non-electric variable control, instruments, etc., can solve the problems of insufficient personnel, untimely patrol inspection, untimely equipment failure treatment, etc., to improve work efficiency, The effect of improving inspection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

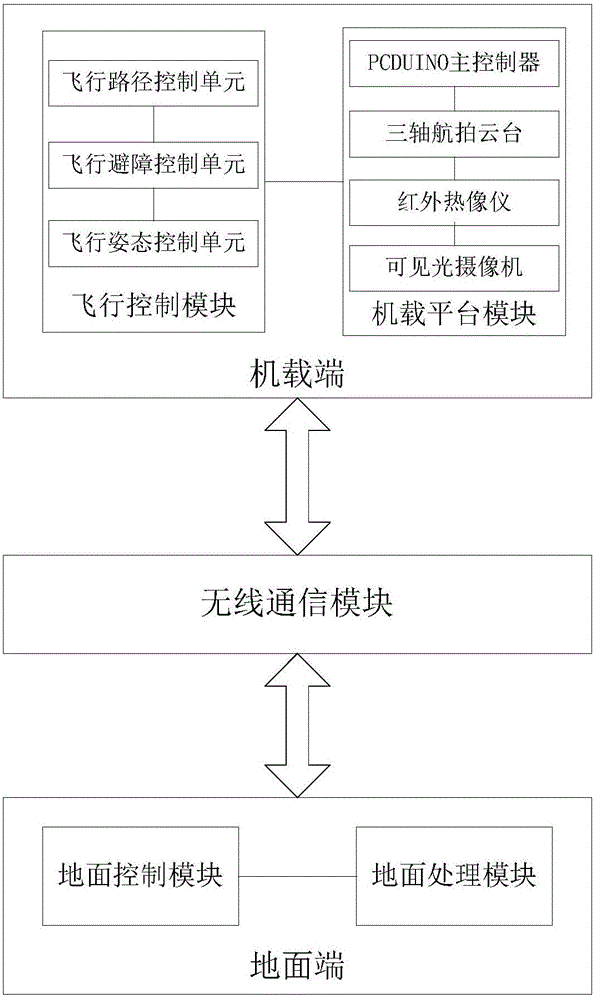

[0043] This embodiment discloses a drone inspection system for photovoltaic power plant electrical equipment, its structural composition block diagram can refer to the attached figure 1 As shown, it mainly includes three parts: airborne terminal, ground terminal, and wireless communication module.

[0044] The airborne terminal is used to control camera or other monitoring equipment to collect image data of electrical equipment of photovoltaic power station. At the same time, it receives the control commands sent from the ground terminal to the airborne terminal, controls the acquisition parameters of the camera or other monitoring equipment, and performs capture control, or controls the zoom zoom to obtain a clearer video image.

[0045] The ground terminal is used to process the data collected and sent back by the airborne terminal, so as to realize the flight and shooting operations of the unmanned aerial vehicle on the ground.

[0046]The wireless communication module is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com