Method for processing diamond-shaped hexagonal honeycombs of honeycomb steam seal

A technology of regular hexagon and processing method, which is applied in the field of honeycomb steam seal diamond-shaped regular hexagon honeycomb processing, can solve the problems of reducing the sealing effect of honeycomb steam seal, and achieve the effect of reducing mechanical vibration and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] This embodiment will be further described below in conjunction with the drawings:

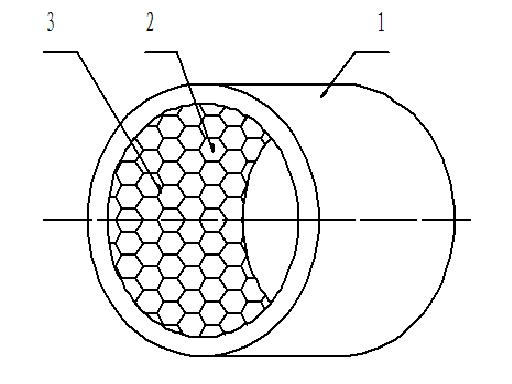

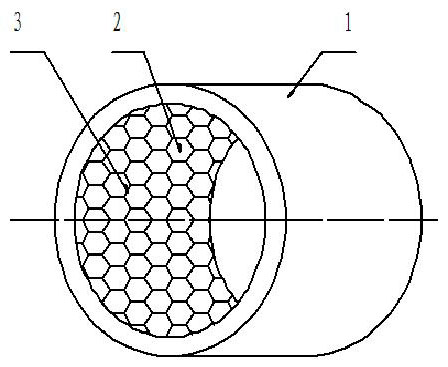

[0009] by figure 1 It can be seen that the honeycomb type steam seal diamond-shaped regular hexagonal honeycomb 1, aluminum honeycomb sealing body, 2, CNC drilling and milling honeycomb blind holes, 3, CNC drilling and milling honeycomb grid.

[0010] The specific implementation steps of the processing method: 1. First, CNC lathe the aluminum seal ring body blank workpiece according to the design drawing size; 2. Install the rotating disc on the worktable of the CNC boring and milling machining center, install the mold on the rotating disc, and place the tire on the The seal ring body workpiece after clamping and turning; 3. Use a dial indicator to align the tire and seal ring body workpiece, and use the pressure plate and screw to tighten the seal ring body workpiece; 4. Install on the spindle of the CNC boring and milling machining center Clamp the drill bit with a right-angle turning too...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com