Coupler buffer device with cutting type energy-absorbing bumper

A buffer device and bumper technology, which is applied to traction devices, transportation and packaging, railway car body parts, etc., can solve the problems of limited energy absorption and energy absorption travel, easy failure, large volume, etc. Good energy absorption effect, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

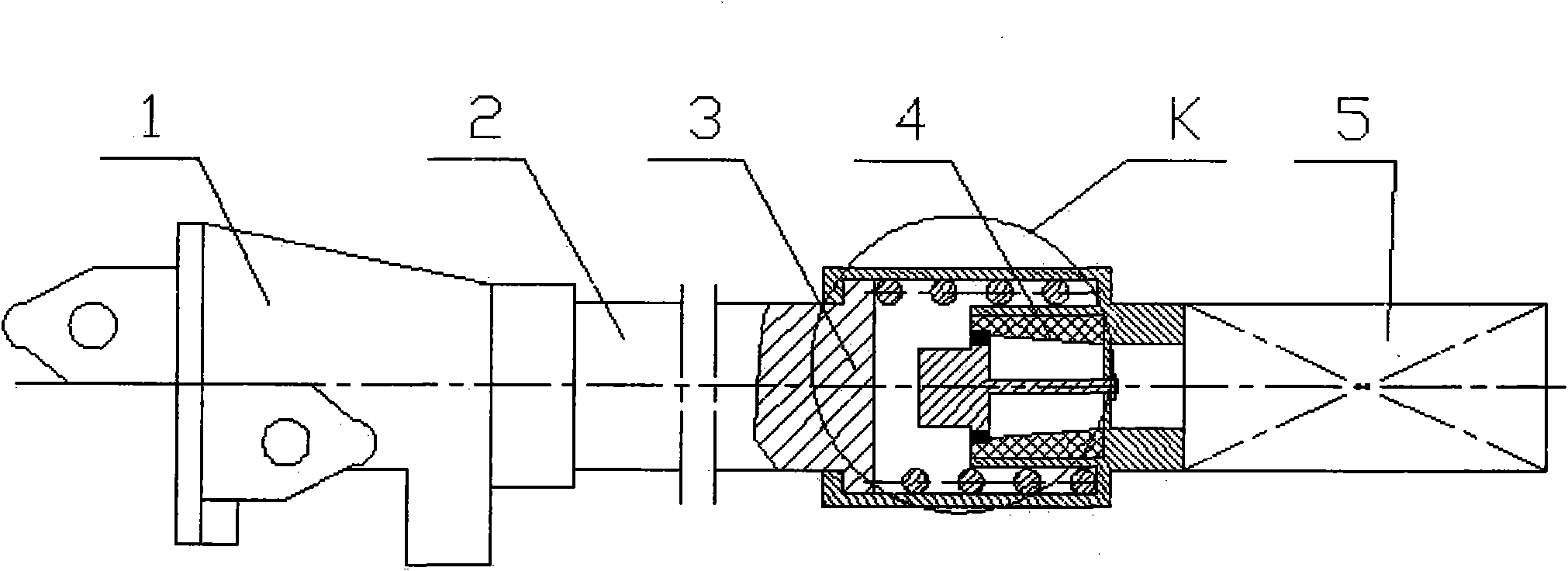

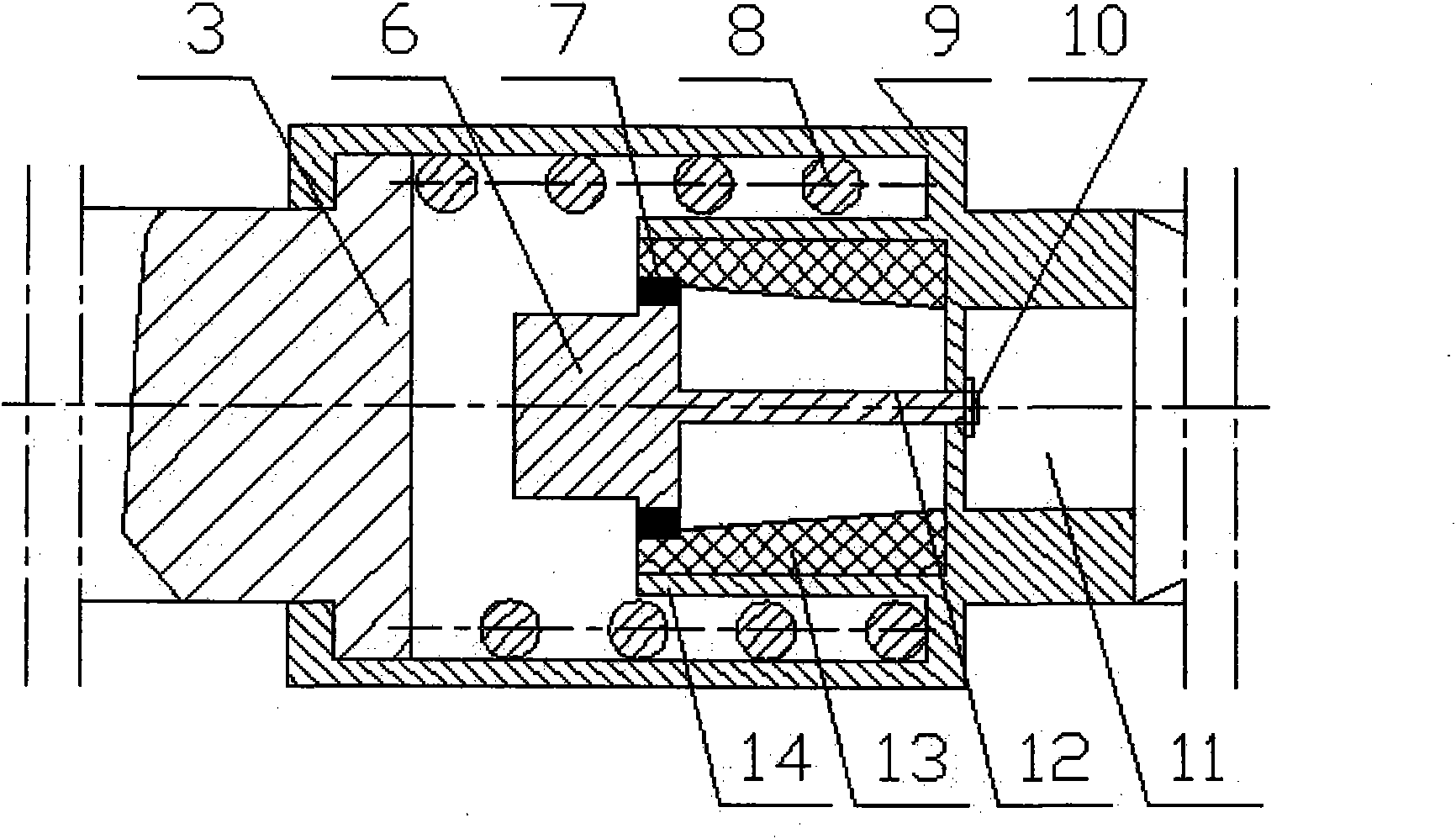

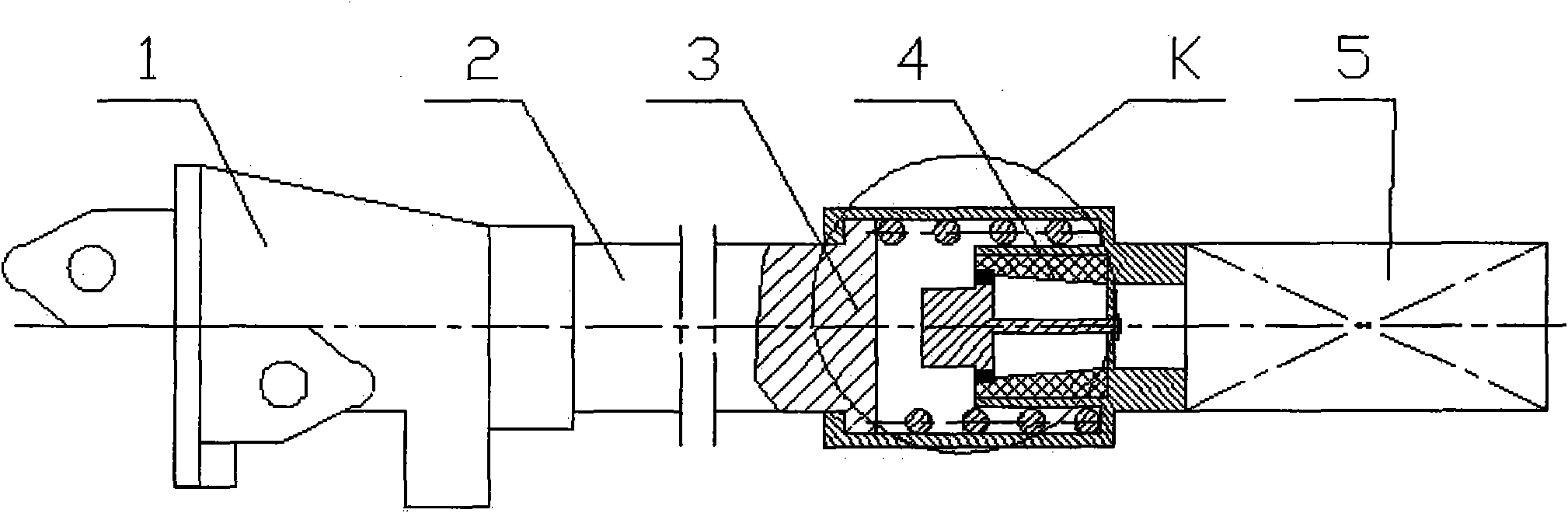

[0027] The hook head 1, the hook body 2, the energy absorber 4, and the buffer 5 are connected in sequence; the energy absorber 4 is a cutting-type energy-absorbing and anti-collision structure, and includes a jacket 9, a knife bar 6, a blade 7, and an energy-absorbing element 13; The outer sleeve 9 is a cylindrical structure with a bottom, in which the energy absorbing element 13 of the cylindrical structure is installed; the open end of the outer sleeve 9 is provided with a stop ring to incorporate the boss of the hook body tail 3 into it, which is a sleeve Type connection; the blade 7 is installed at one end of the knife shaft 6, and its blade is in contact with the energy absorbing element 13; the free end of the knife shaft 6 is in contact with the end of the boss of the hook body tail 3. When the blades 7 are in a group, the cutting edges are evenly distributed on the same circumference. The cutting edges of the blade 7 are arranged in a spiral shape. The energy absorbin...

Embodiment 2

[0030] The hook head 1, the hook body 2, the energy absorber 4, and the buffer 5 are connected in sequence; the energy absorber 4 is a cutting-type energy-absorbing and anti-collision structure, including a jacket 9, a knife bar 6, a blade 7, a threshold spring 8, and a suction The energy element 13 and the inner sleeve 14; the outer sleeve 9 and the inner sleeve 14 constitute a sandwich cylinder structure with a low inner and a high outer sleeve, and the inner sleeve 14 is equipped with the energy-absorbing element 13 of the cylinder structure; the open end of the outer sleeve 9 is provided with a stop The retaining ring incorporates the boss of the hook body tail 3, a threshold spring 8 is installed between the outer sleeve 9 and the inner sleeve 14. The free end of the threshold spring 8 is in contact with the boss end of the hook body tail 3; the inner wall of the inner sleeve 14 is set A guide plate with a through hole, the guide plate forms the inner cavity of the inner sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com