Chemical fiber filament flattening web former

A flattening roller and flattening device technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of uneven thickness, poor transverse tension, small entanglement and weaving amplitude, and achieve the effect of flattening and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

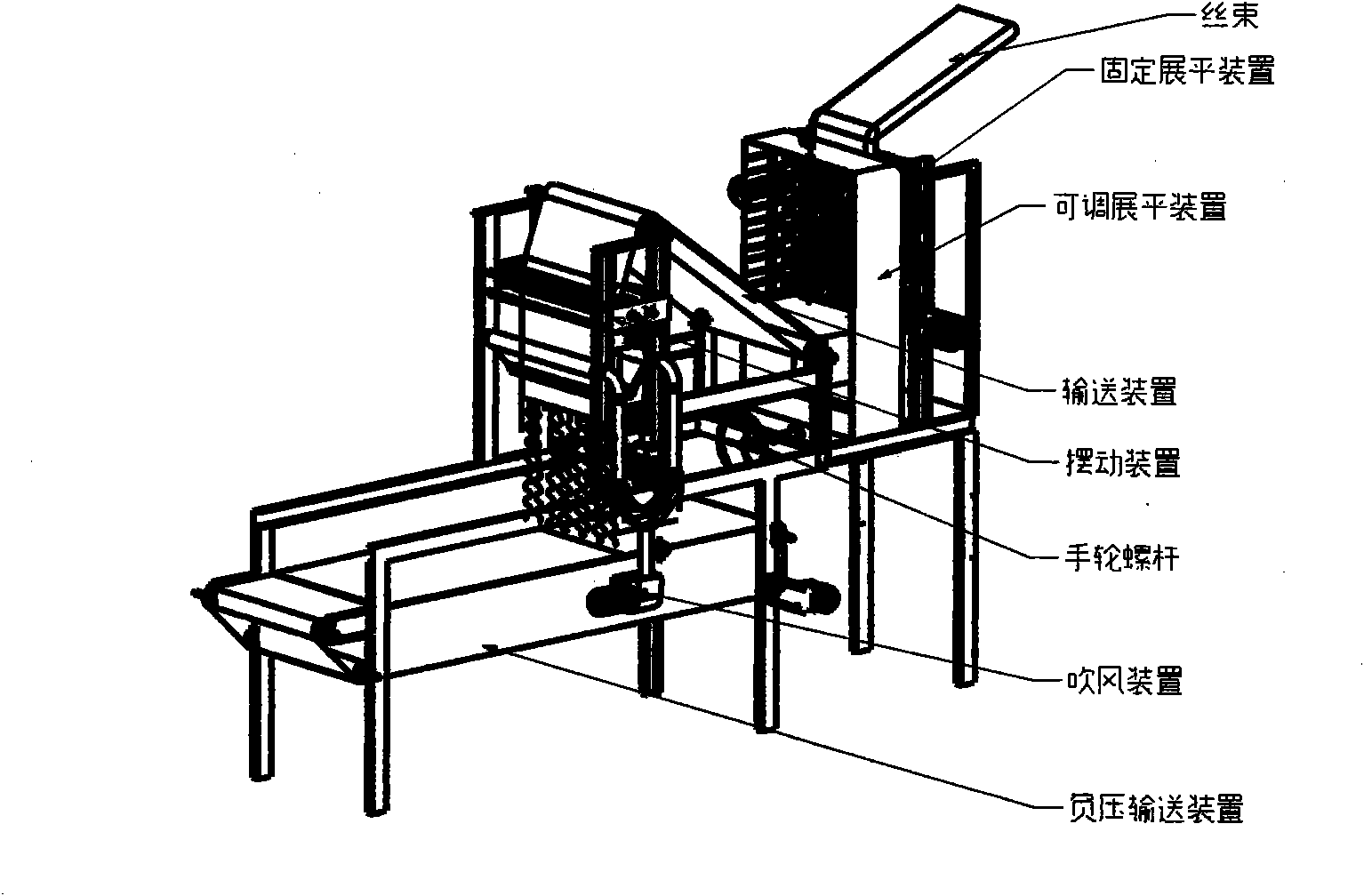

[0013] in figure 1 In the process, the tow (1) is flattened by the fixed flattening device (2) and the adjustable flattening device (3), the handwheel screw (4) is used to adjust the counter-rolling gap, and it is sent by the conveying device (5). Enter the swing device (6) to close. The filaments that are swung into the blowing device (7) through the nip roll and blown into a tangled and braided state are adsorbed on the negative pressure conveying device (8) and enter the next process.

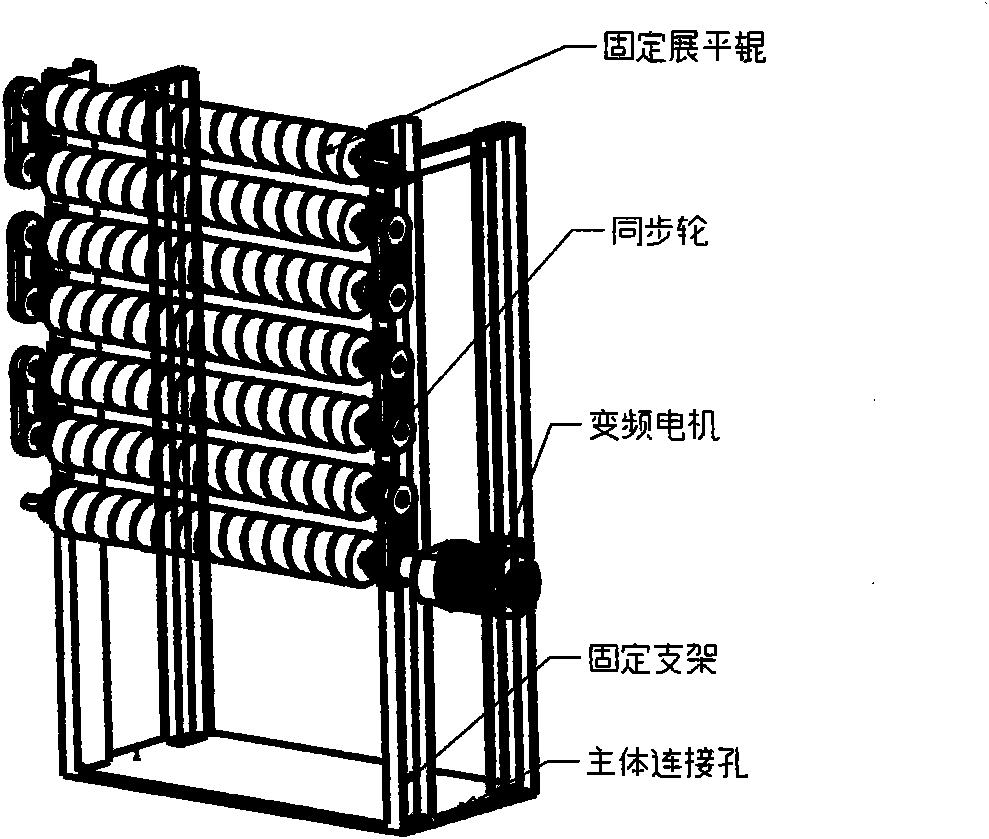

[0014] in figure 2 In the combination of a plurality of fixed flattening rollers (9), a plurality of synchronous wheels (10), a frequency conversion motor (11) and a fixed bracket (12), the main body connecting holes (13) and Image 6 The fixing bracket connection holes (34) distributed in the middle are connected and fixed.

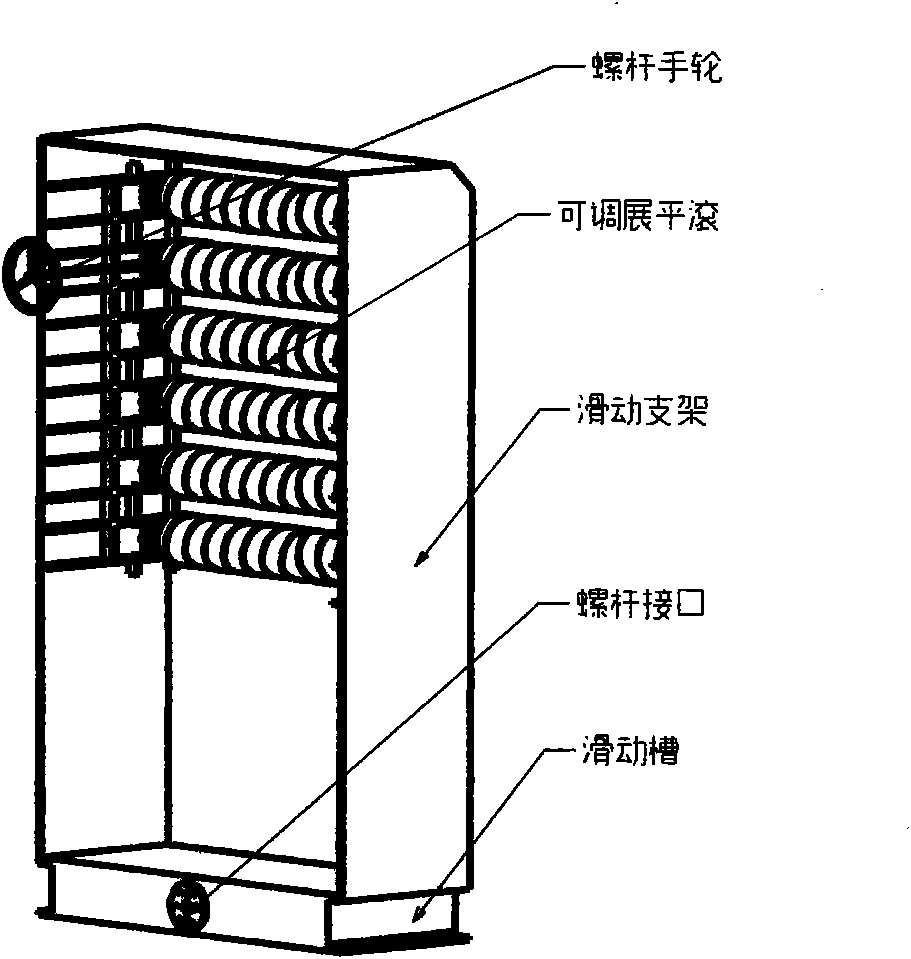

[0015] in image 3 In the process, the screw handwheel (14) is used to adjust the gap between each adjustable flattening roller (15) and the fixed flattening roller (9). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com