Underground pipeline or culvert maintenance vehicle

A technology of underground pipelines and maintenance vehicles, which is applied in the repair of waterway systems, road bottom layers, and infrastructure structures. It can solve the problems of roads affecting traffic, long construction time, and neglect of maintenance, so as to reduce traffic congestion time and work. Difficulty, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

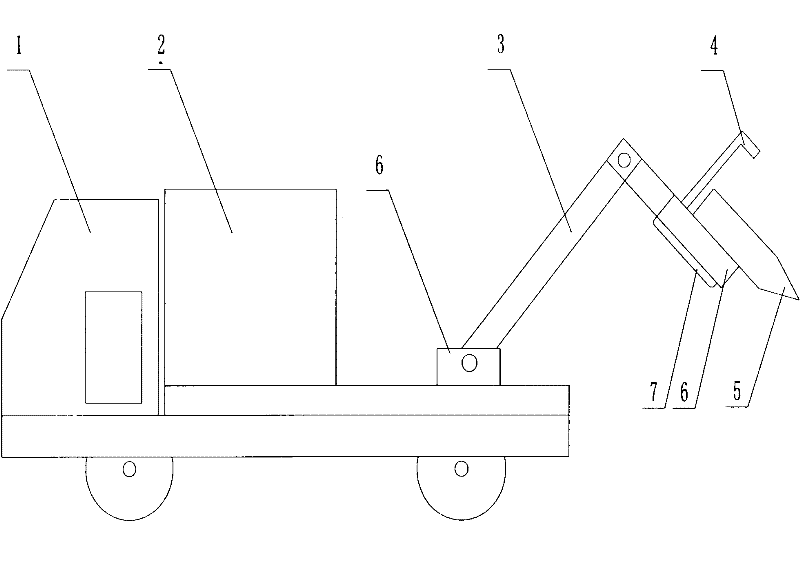

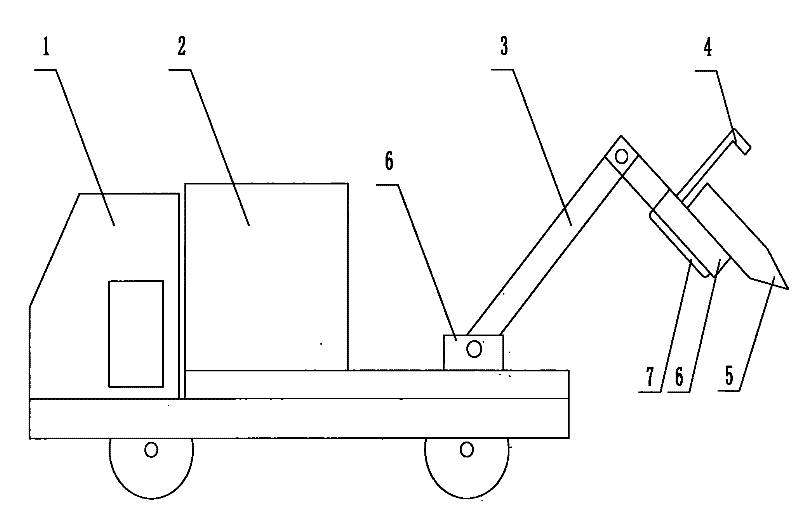

[0013] Such as figure 1 As shown, an underground pipeline or culvert maintenance vehicle includes a car body 1, the front part of the car body 1 is a driver's cab, and there is an operating room 2 behind the driver's cab, and there are operating components for the operator in the operating room 2 and the display screen, there is a retractable mechanical arm 3 behind the operating room 2 on the vehicle body 1, and the mechanical arm 3 is connected to the pan-tilt 6 on the vehicle body 1, and the connection between the pan-tilt 6 and the mechanical arm 3 There is a hinge. The front end of the mechanical arm 3 is a workbench, the power device of the workbench is set in the car body 1, and the controller of the workbench is set in the operating room 2; the workbench is divided into a crawler wheel 7, a loading platform 6 and a working head 5 , the crawler wheel 7 can deliver the workbench to the maintenance site in the pipeline or culvert by running on the inner wall of the pipe....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com