OLED (Organic Light Emitting Diode) display screen packaging equipment and compression packaging method

A technology for packaging equipment and display screens, which is applied in electrical components, electric solid-state devices, circuits, etc., and can solve problems such as cumbersomeness, reduced production efficiency, and complex OLED display production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

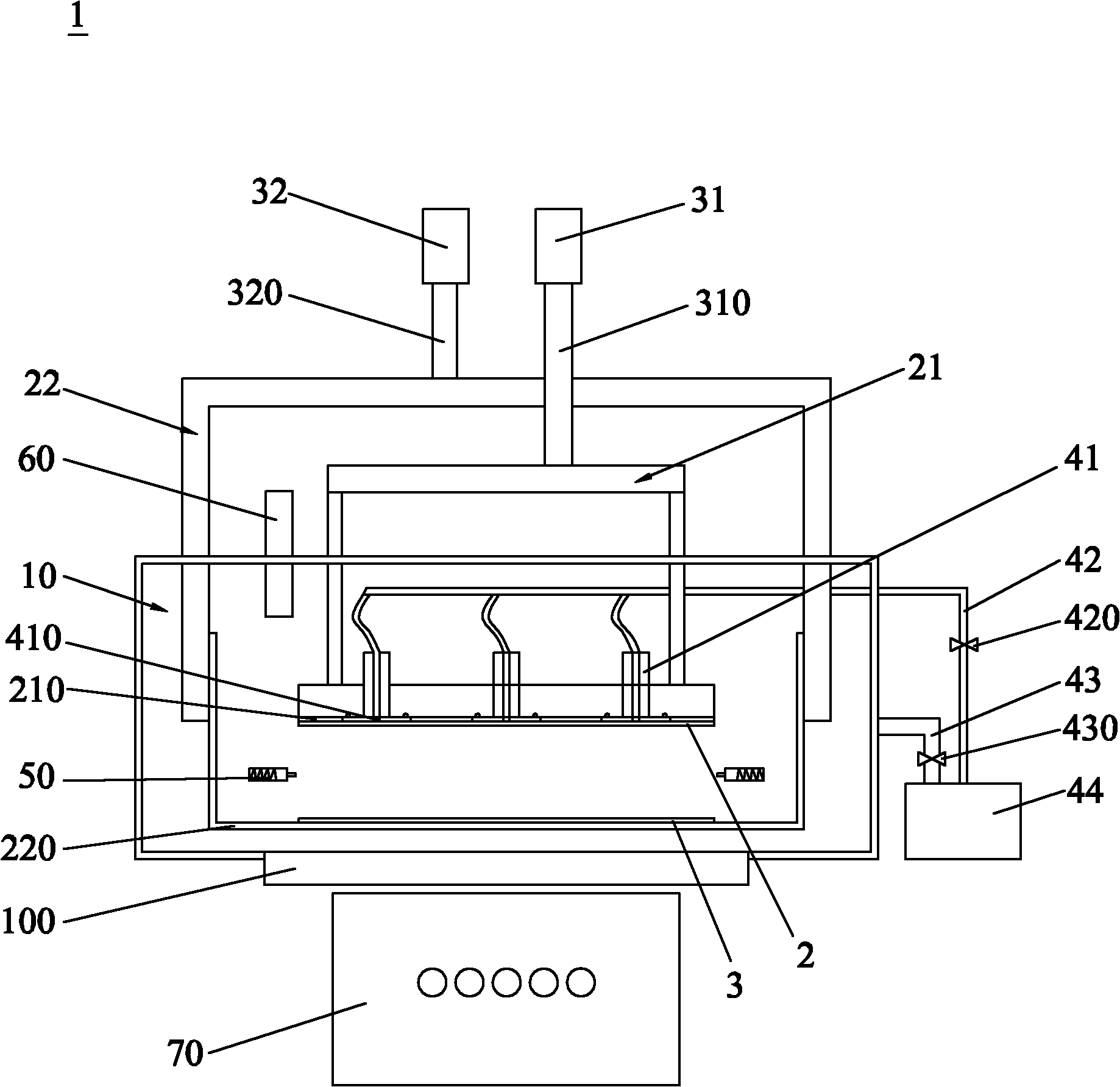

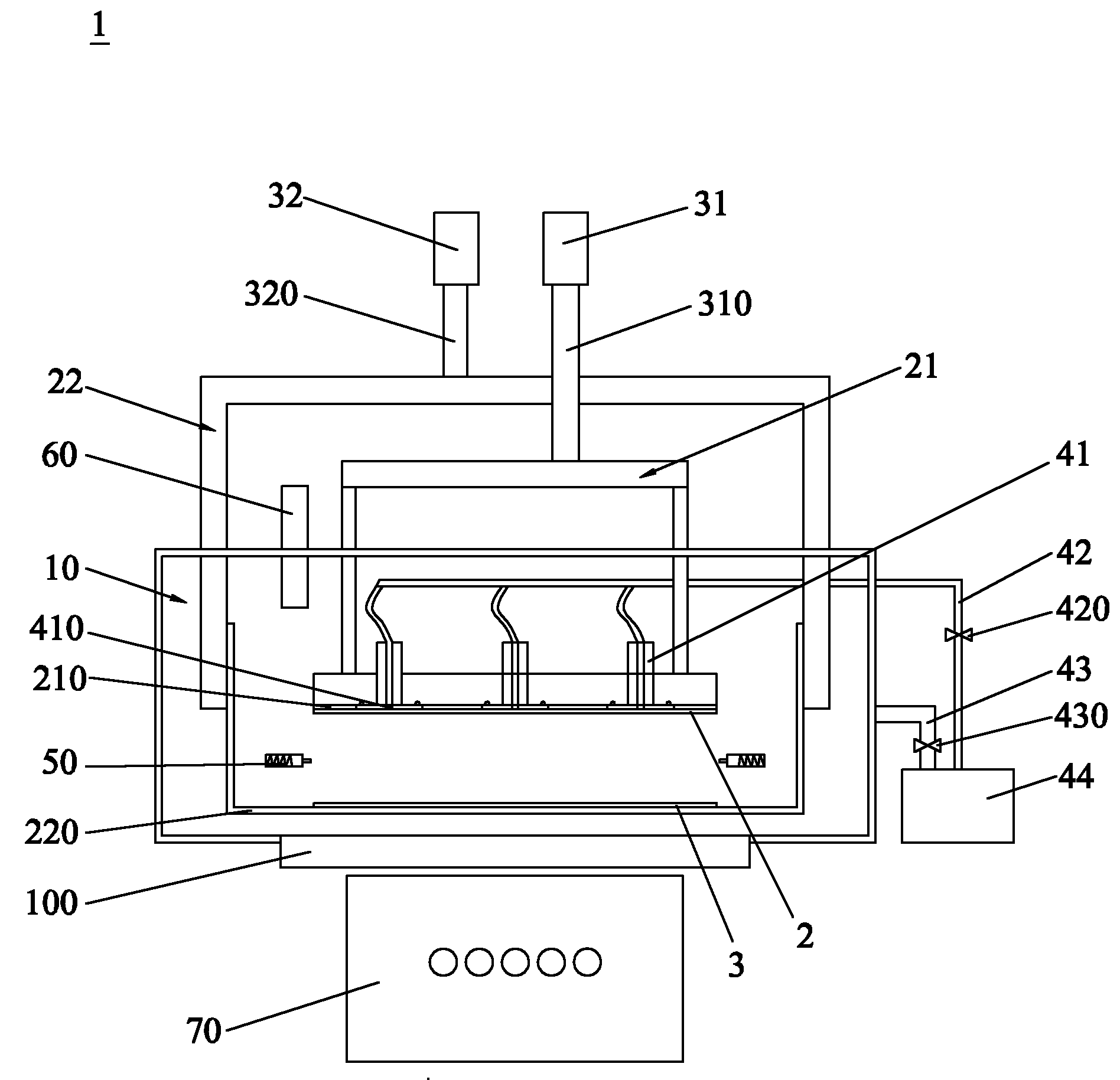

[0028] refer to figure 1 , the OLED display packaging device 1 of the present invention comprises a sealed chamber 10, a first press-fit mechanism 21, a second press-fit mechanism 22, a first motor 31, a second motor 32, an air pump assembly and a pump for vacuuming. device 44. The first motor 31 has a first transmission rod 310, one end of the first transmission rod 310 is telescopically connected to the first motor 31, and the other end is fixedly connected to the first pressing mechanism 21, the first The motor 31 drives the first transmission rod 310 to expand and contract up and down, thereby driving the first pressing mechanism 21 to move up and down; the second motor 32 has a second transmission rod 320, and one end of the second transmission rod 320 is retractable The other end is fixedly connected to the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com