Maintenance-free air cooler

An air cooler, maintenance-free technology, used in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of reliability decline of large motors, and achieve the effect of completely practical structure, improved reliability, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

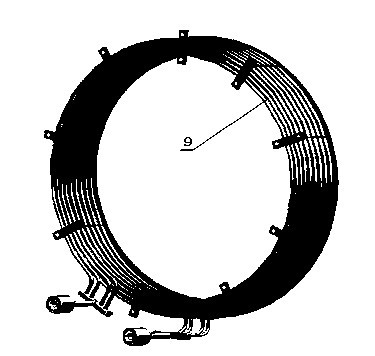

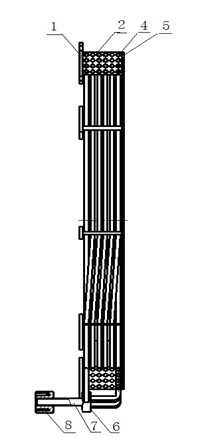

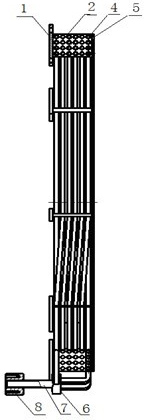

[0017] A maintenance-free air cooler, comprising a number of cooling pipes connected in series front and back to form a ring and then superimposed up and down to form four cooling elements 4 spirally wound and supporting plates 2 arranged on both sides of the cooling elements 4, the supporting plates 2 One end is fixed on the mounting plate 1 located at the upper end of the cooling element 4, and the other end is fixed on the end plate 5 located at the lower end of the cooling element 4. The outlet and the inlet end of the cooling element 4 are connected to the connecting pipe 7 through the water collecting pipe 6. The described A connecting flange 8 is also provided on the connecting pipe 7 .

[0018] The cooling parts can be stacked adjacently and sequentially. The inlets of the cooling parts are connected in parallel and connected to the water collecting pipes 6, and the outlets are connected in parallel and connected to the water collecting pipes 6; The inlet of the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com