Double-layer dust collection device of tabletting machine

A technology of a dust collector and a tablet press, which is applied to presses, material forming presses, manufacturing tools, etc., can solve the problems of difficulty in removing powder, reducing production efficiency, sticking and punching under punching, etc., and achieve uniform gap size. , The effect of powder agglomeration is convenient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

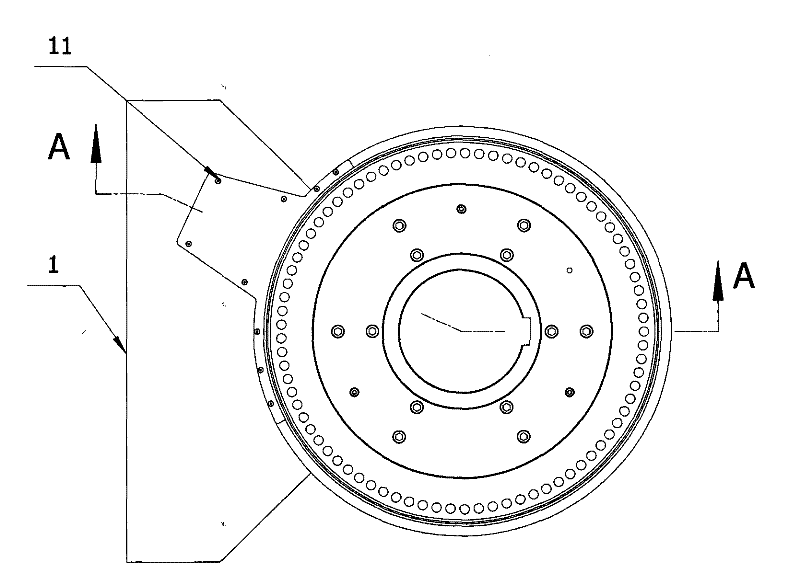

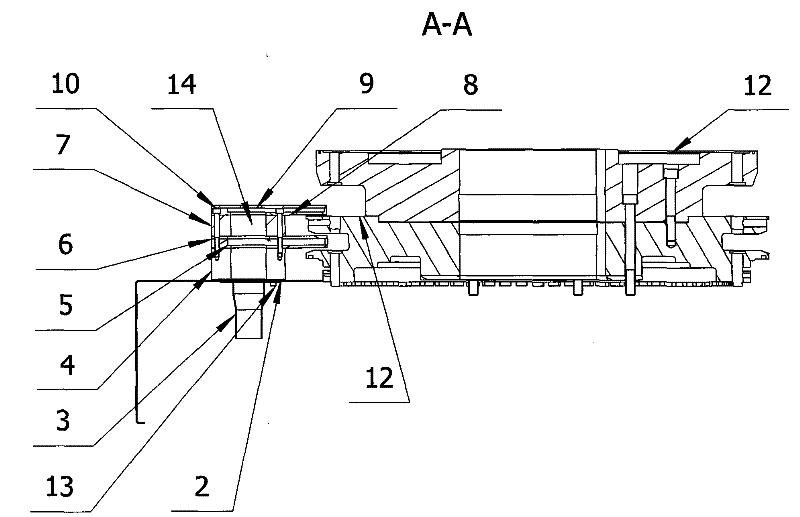

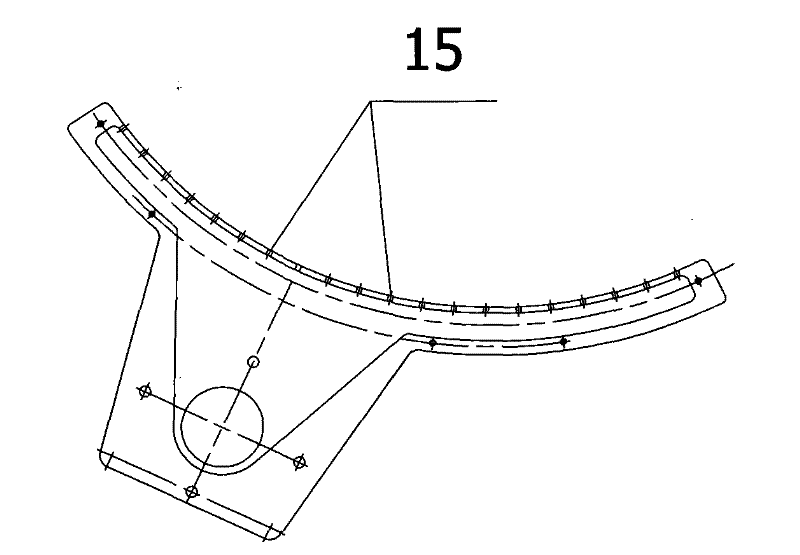

[0020] Figure 1~2 It is a cross-sectional view and a top view of the double-layer dust collection device involved in the present invention. The double-layer vacuum device includes a table cover 1, a gasket 2, a suction pipe joint 3, a lower pad 4, a lower suction plate 5, a lower suction cover 6, an upper pad 7, an upper suction plate 8, Upper suction cover 9, hexagon socket head cap screw 10, countersunk head screw 11, turntable 12, hexagon socket cap screw 13. Among them, the suction pipe joint 3 is installed on the lower surface of the table cover 1, the sealing gasket 2 is installed on the upper surface of the table cover 1, and the lower pad 4 is installed on the top of the sealing gasket 2, and the table cover 1 and the table cover 1 are sealed with socket head cap screws 13. The pad 2, the suction pipe joint 3, and the lower pad 4 are connected and fastened, and then the lower suction plate 5, the lower suction cover 6, the upper pad 7, and the upper powder suction pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com