Passenger conveying device

A technology of passenger conveying equipment and steps, used in transportation and packaging, escalators, etc., can solve the problems of loss of balance, fall, and high friction coefficient of shoe surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

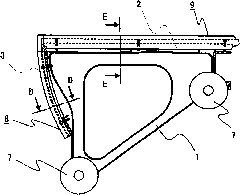

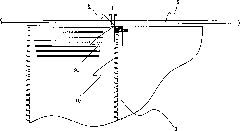

[0086] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings. An escalator as an example of a passenger conveying device according to the present invention has: a frame, which is provided on a building structure; an entrance and exit floor, which is respectively provided at both ends in the longitudinal direction of the frame; a step chain, The step chain is circularly connected to move circularly between the entrance and exit floors; a plurality of steps 1, the plurality of steps 1 are connected to the step chain; railings, the railings are vertically arranged on the frame on both sides of the plurality of steps and skirt guards 5, the skirt guards 5 are respectively arranged at two sides of the steps at intervals at the lower part of the railing. Since each structure of the above-mentioned escalator is a known technology, the illustration of most of the structures in the structure is omitted.

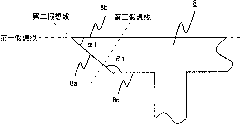

[0087] The steps 1 according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com