Image forming apparatus for preventing image deterioration caused by fallen conductive brush and scatter of developer

An image and latent image carrier technology, which is applied in corona discharge devices, electric recording technology using charge patterns, equipment for electric recording technology using charge patterns, etc., can solve problems such as difficult to meet, and prevent electrostatic potential like disordered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

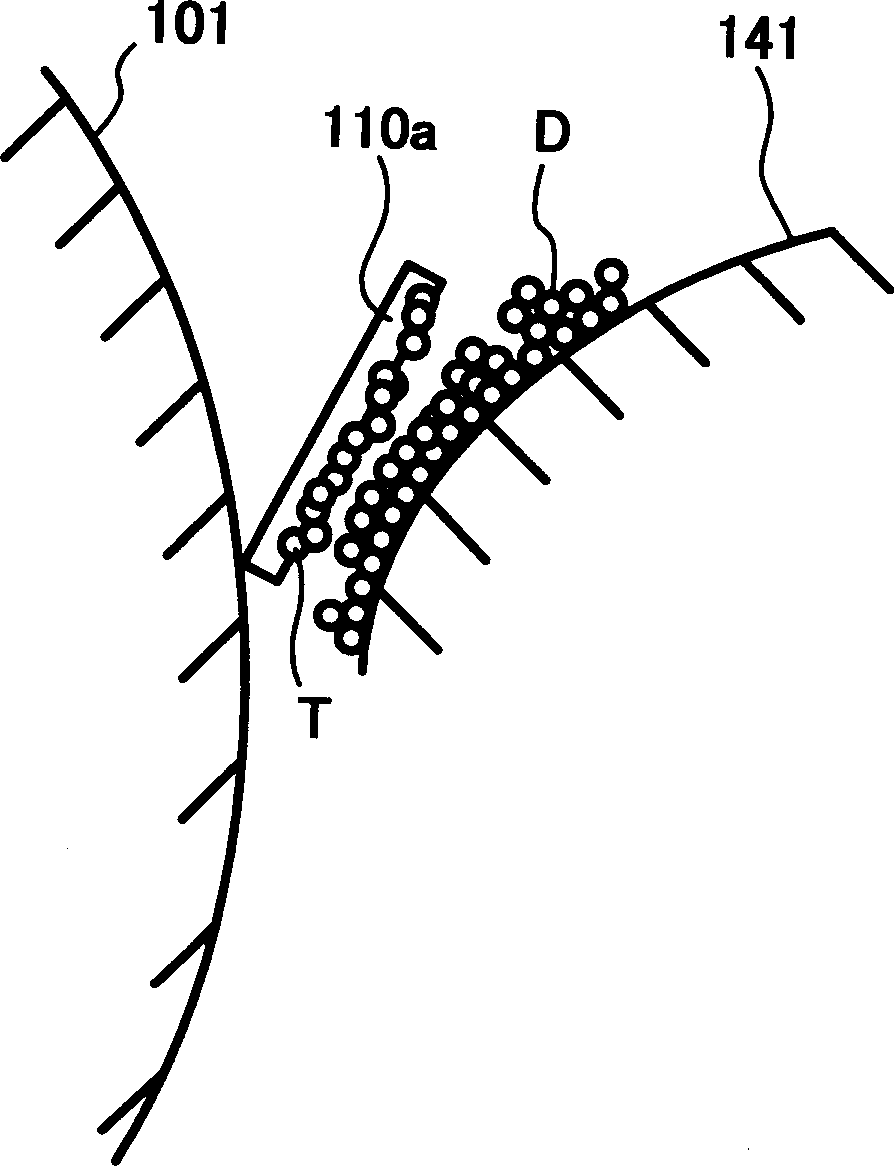

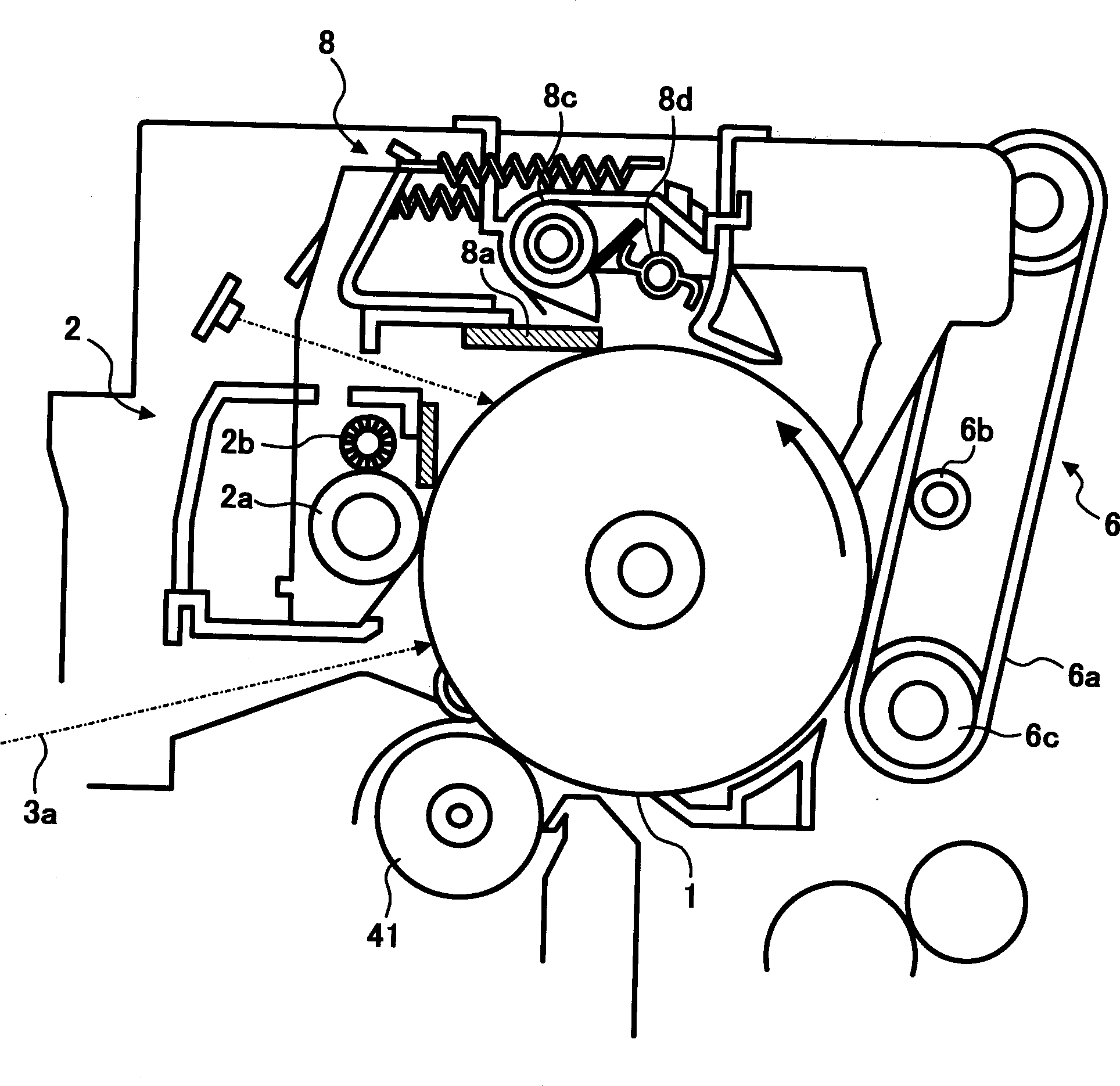

[0116] Figure 10 and Figure 11 It is an explanatory diagram of the installation position of the main development magnetic pole P1b of the magnetic roller 41, and the installation position of the main development magnetic pole P1b of the magnetic roller 41 is preferably 3° to 9° upstream in the developer conveying direction from the position closest to the development nip.

[0117] If the main pole angle is less than 3°, for example Figure 10 Among them, the main magnetic pole angle of the magnetic roller is 0°, the ends of the first inlet seal 10a and the second inlet seal 10b face the auxiliary magnetic pole P1a, and the magnetic ears of the magnetic brush caused by the auxiliary magnetic pole P1a stand up and contact the photoreceptor. Drum 1 is connected. Therefore, the magnetic brush due to the auxiliary magnetic pole P1 a and the magnetic brush due to the developing main magnetic pole P1 b rub the electrostatic latent image on the photoreceptor drum 1 , and the image...

no. 2 example

[0137] In order to confirm the effect of the structure of the present invention described above, an evaluation test was performed, and the thickness Y1 of the first inlet seal 10 a and the thickness Y2 of the second inlet seal 10 b were both set to 0.2 mm. In this evaluation test, cut off a quarter of the brush from the brush roller 2b, make it attached to a new brush roller 2b, carry out 500 copying tests each, and count the number of sheets with abnormal images. The results are listed in Table 2.

[0138] Developing roller condition

The number of images with abnormal black stripes

Conventional developing roller

500 / 500

This example

developing roller

Main pole angle 0°

186 / 500

Main Pole Angle 3°

3 / 500

Main Pole Angle 6°

0 / 500

Main Pole Angle 9°

3 / 500

Main Pole Angle 12°

256 / 500

[0139] In Table 2, "the developing roller of this example" means Figure 10 and Figure 11 The developing ...

no. 3 example

[0163] The test conditions are as follows:

[0164] Developing gap Gp: 0.4mm

[0165] Developer uptake ρ: 90mg / cm 2

[0166] Toner particle size: 6.5μm

[0167] Carrier particle size: 50μm

[0168] Linear speed Vs of photosensitive drum 1: 330 mm / sec

[0169] Diameter φ of photoreceptor drum 1: 100mm

[0170] Linear velocity ratio of the developing roller 41 to the photoreceptor drum 1: 2.0

[0171] Diameter φ of developing roller 41: 25 mm

[0172] When the linear velocity of the developing roller 41 is equal to or less than 250 mm / sec, it can be confirmed that developer scattering does not occur near the developing area, but when the linear velocity of the developing roller 41 exceeds 250 mm / sec, developer scattering occurs, and the first inlet is sealed. Item 10a becomes necessary.

[0173] Here, the inventors of the present invention conducted experiments using the above copier, and the image quality deteriorated over a long period of use. As a result of research ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com