Bearing cage for rolling-element bearing

A technology for bearing cages and rolling elements, applied in rolling contact bearings, rotating bearings, bearings, etc., can solve problems such as inapplicability, increased friction of rolling elements, loss of radial and axial retention of cages, etc., to achieve Low weight, high RPM, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

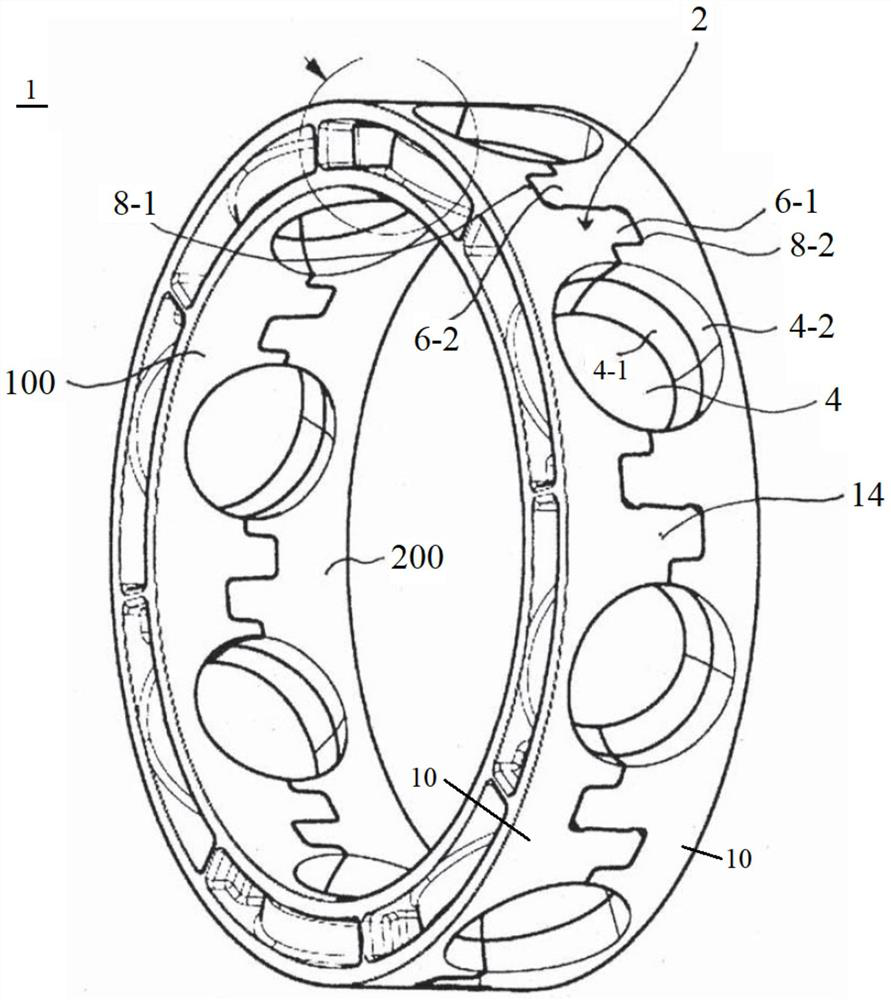

[0071] figure 1 A schematic spatial illustration of a bearing cage 1 for a ball bearing comprising a first bearing cage half 100 and a second bearing cage half 200 is shown. In this case, the bearing cage halves 100 and 200 are designed identically. if possible from figure 1 It is further seen that the bearing cage 1 comprises bridges 2 between which are formed cage pockets 4 in which rolling elements (not shown) can be received. Here, the cage cavity 4 has a circular ring shape; this means that the cage cavity 4 is formed spherically on its radial inside 4-1, while the cage cavity 4 is formed on its radial outside 4-2 as Cylindrical. This annular design enables the rolling elements (i.e. balls) to be well guided on the radially inner side 4-1 and completely enclosed in the cavity 4, while on their radially outer area 4-2 , The rolling elements and the bearing cage 1 have a certain distance, so that the lubricant can penetrate into the gap between the rolling elements and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com