Process for preparing low-basis-weight corrugated paper

A preparation process, corrugated paper technology, applied in the field of papermaking, can solve the problems of not being able to provide economic benefits to enterprises, and high quantitative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

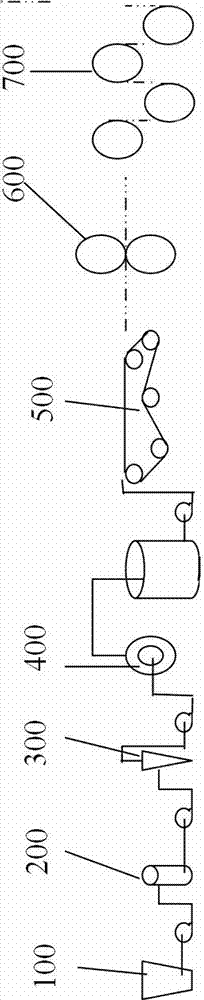

[0037] A preparation process of low weight corrugated paper, adopting such as figure 1 The shown processing equipment carries out production, including the following steps.

[0038] a. Put American waste and European waste as waste paper into the pulper 100 to shred to form pulp. The ratio of American waste to European waste is 1:2~1:4.

[0039] b. The pulp passes through the pressure screen 200 and the slag remover 300 in sequence to remove impurities.

[0040] c. The pulp after impurity removal is input to the grinding disc 400 for beating treatment to obtain pulp.

[0041] d. Add auxiliary materials to the slurry. The auxiliary materials include strengthening agent, sizing agent and aluminum sulfate. The adding amount of strengthening agent is 25~35 Kg / T waste paper, and the adding amount of sizing agent is 10~15 Kg / T waste paper , the amount of aluminum sulfate added is 15~20 Kg / T waste paper.

[0042] e. Pump the slurry to the wire section 500 for molding and dehydrati...

Embodiment 2

[0047] A preparation process of low weight corrugated paper, adopting such as figure 1 The shown processing equipment carries out production, including the following steps.

[0048] a. Put American waste and European waste as waste paper into the pulper 100 to shred to form pulp. The ratio of American waste and European waste is 1:3, that is, the content of American waste is 25%, and the content of European waste is 75%.

[0049] b. The pulp passes through the pressure screen 200 and the slag remover 300 in sequence to remove impurities.

[0050] c. The pulp after impurity removal is input to the grinding disc 400 for beating treatment to obtain pulp. That is, the fibers are divided into filaments through the friction between the grinding teeth of the grinding disc 400 and the fibers, so that the slurry is processed.

[0051] d, Add auxiliary materials to the slurry, auxiliary materials include strengthening agent, sizing agent and aluminum sulfate, the addition of strengthe...

Embodiment 3

[0057] A preparation process of low weight corrugated paper, adopting such as figure 1 The shown processing equipment carries out production, including the following steps.

[0058] a. Add American waste and European waste as waste paper into the pulper 100 to shred to form pulp. The ratio of American waste to European waste is 1:2.

[0059] b. The pulp passes through the pressure screen 200 and the slag remover 300 in sequence to remove impurities.

[0060] c. The pulp after impurity removal is input to the grinding disc 400 for beating treatment to obtain pulp. That is, the fibers are divided into filaments through the friction between the grinding teeth of the grinding disc 400 and the fibers, so that the slurry is processed.

[0061] d, Add auxiliary materials to the slurry, auxiliary materials include strengthening agent, sizing agent and aluminum sulfate, the addition of strengthening agent is 25 Kg / T waste paper, the addition of sizing agent is 15 Kg / T waste paper, alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com