Ball maintenance chain, its preparation method and linear movement mechanism

A technology for retaining chains and balls, which is applied in the field of linear motion mechanisms and ball retaining chains, and can solve the problems of easy generation of burrs, unsmooth operation, and difficult demoulding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

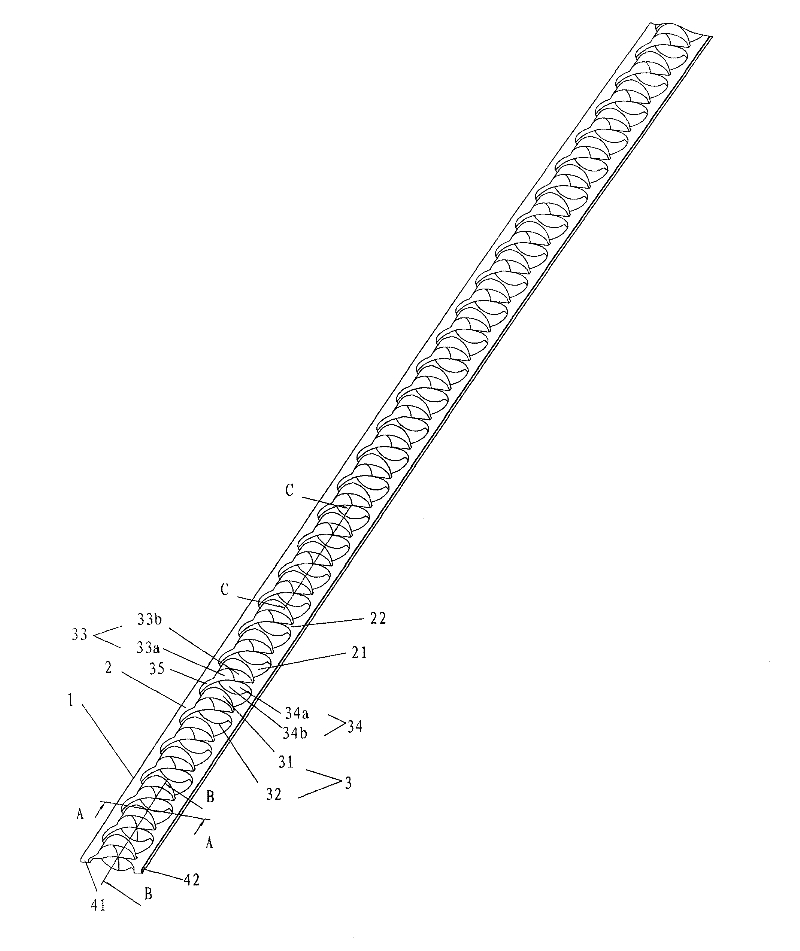

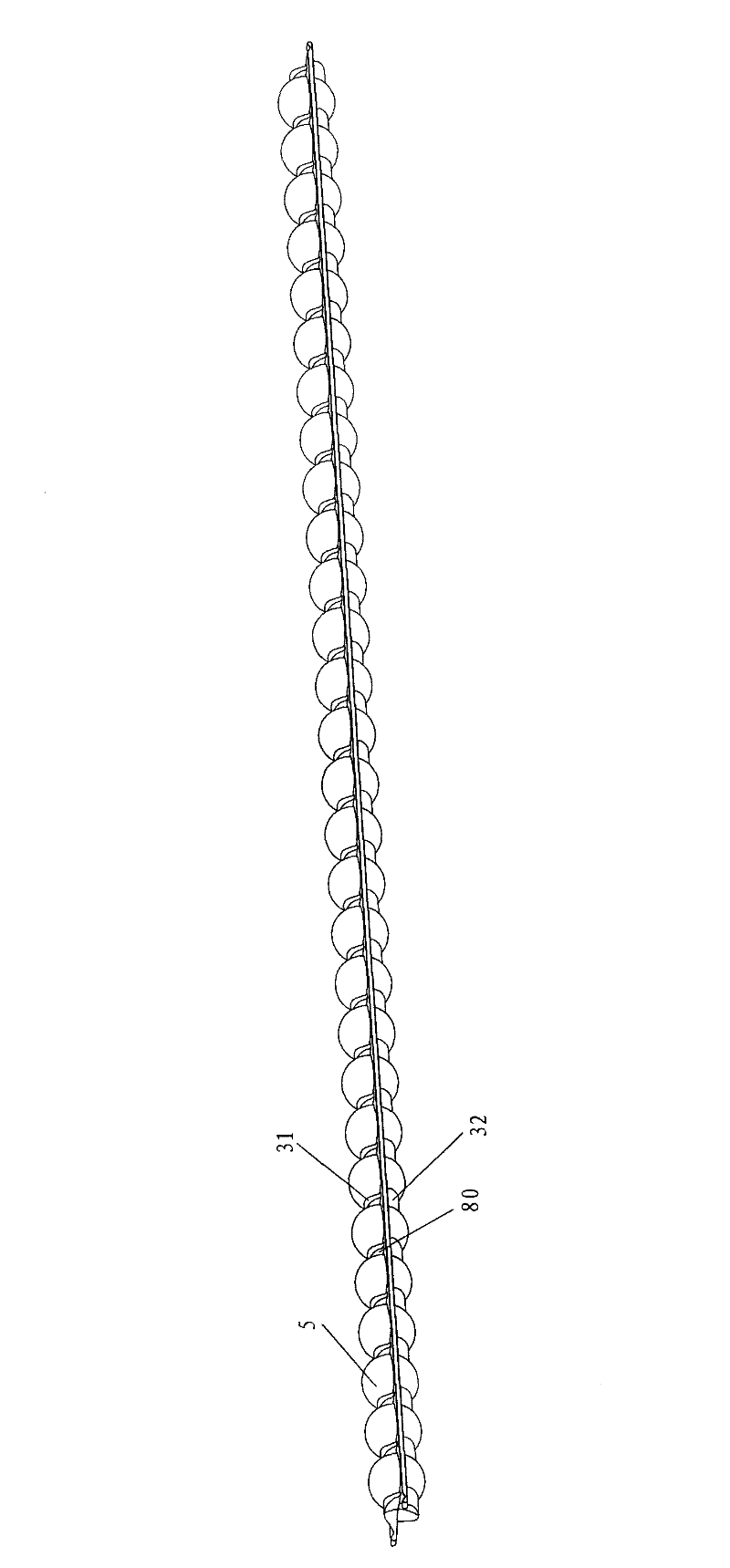

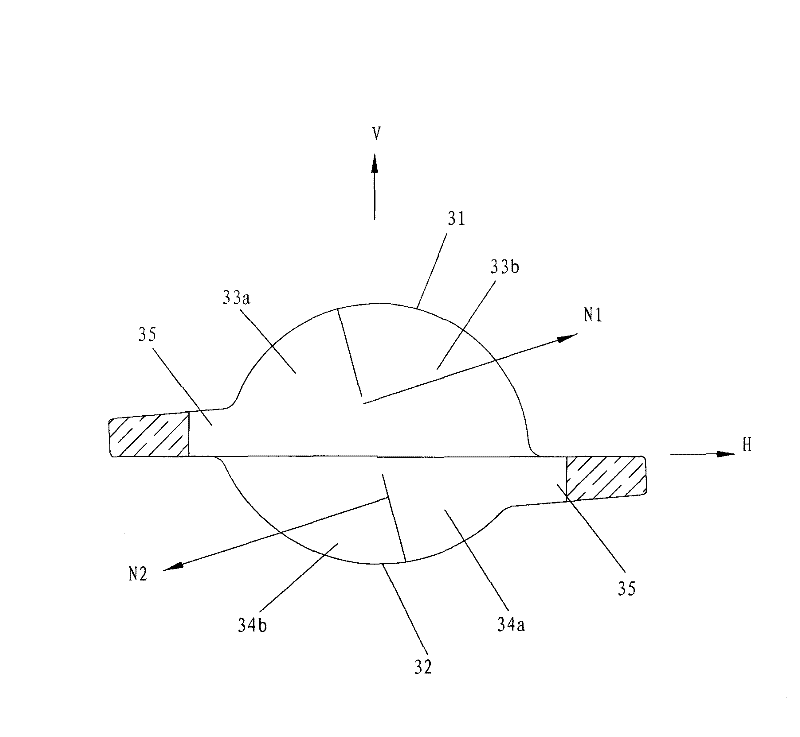

[0039] See figure 1 As shown, the present invention is a ball retaining chain. The ball retaining chain 1 is composed of a flat strip 2 and a plurality of spacer blocks 3. The flat strip 2 has axially arranged holes 21, and a spacer is formed between the holes 21 The sheet 22 separates two holes 21 on which the spacer block 3 is combined. The spacer block 3 is divided into an upper spacer block 31 and a lower spacer block 32. The hole 21 forms a hole in the vertical direction of the flat strip 2 and the two spacer blocks 3 Face 35; such as figure 2 As shown, a row of balls 5 are separated by spacers 3 and held in holes 21, such as figure 1 As shown, the surfaces corresponding to the holes 21 of the upper spacer block 31 and the lower spacer block 32 are a smooth surface 33, 34, and a part of the smooth surface 33, 34 is a spherical covering surface 33a, 34a slightly larger than the ball 5. And smoothly connect with the hole surface 35 on the flat strip 2, and then smoothly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com