Ventilating mechanism of transmission

A transmission and air vent technology, which is applied to mechanical equipment, geared components, transmission parts, etc., can solve the problems that oil and air cannot be completely separated, shape, capacity, configuration constraints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

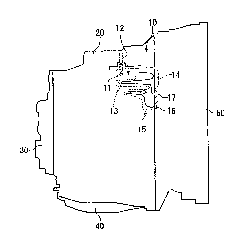

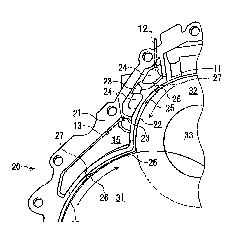

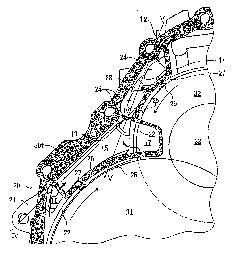

[0028] figure 1 An automatic transmission including the breather mechanism 10 of the present invention is shown. The automatic transmission includes a transmission case 20 , a side cover 30 fastened to the transmission case 20 by bolts, an oil pan 40 , and a shifter case 50 . Shafts, gears, clutches, brakes, and a hydraulic control circuit are arranged in the transmission case 20 , and a torque converter is arranged in the converter case 50 .

[0029] A vent hole 11 for releasing the pressure inside the transmission is formed in an upper portion of the transmission case 20 , and a vent pipe 12 is inserted into the vent hole 11 .

[0030] The transmission case 20 and the converter case 50 are respectively formed with grooves 13, 14 in the vicinity of their joint surfaces, and by making these grooves 13, 14 face each other, a breather chamber 15 is formed throughout the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap