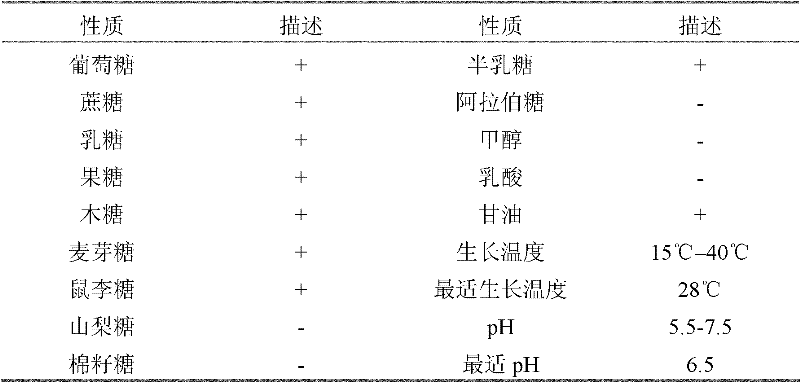

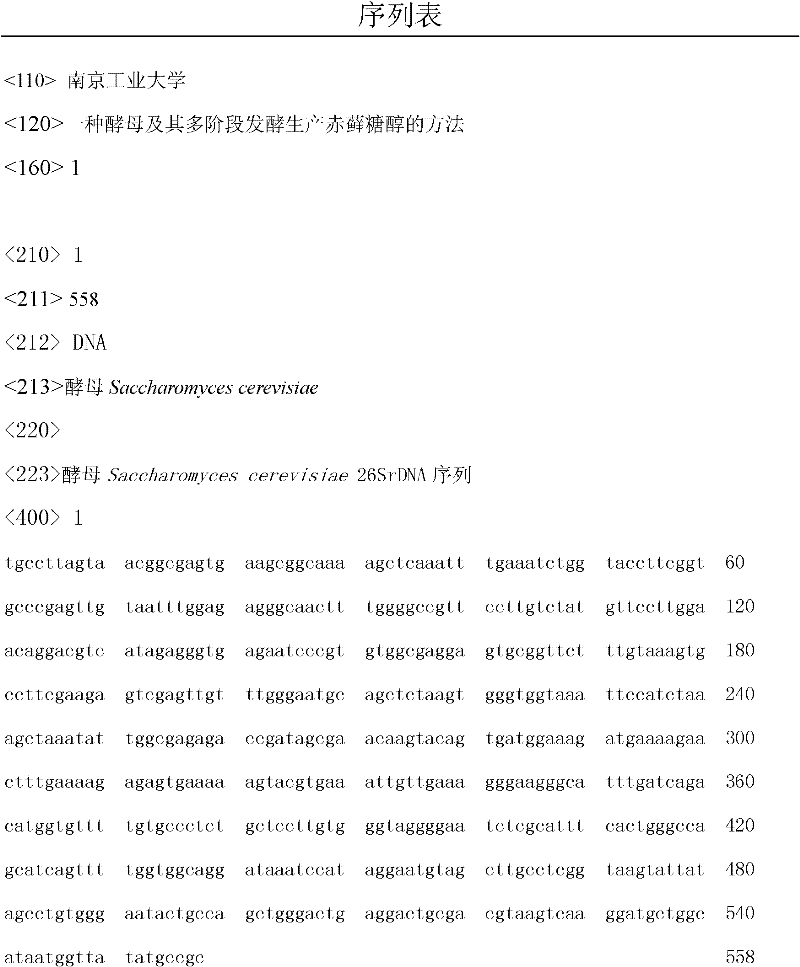

Yeast and method for producing erythritol by multistage yeast fermentation

An erythritol, multi-stage technology, applied in the field of high-yielding erythritol-producing yeasts, can solve the problems of long fermentation cycle, many extraction and separation steps, inhibition, etc., and achieve low cost, high yield and improved yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] ①Cultivation of seeds

[0043] Pick 1 yeast Saccharomyces cerevisiae NJWGYH30566 (CGMCCNo.4349) colony from the PDA plate into a 500mL Erlenmeyer flask filled with 25mL of seed medium, and cultivate it in a shaking table with a temperature of 25°C, a pH of 5.5, and a rotation speed of 150rpm for 40h. Obtain seed culture fluid;

[0044] The composition of the above seed medium is (g / L): 150 glucose, 10 yeast extract, and 3 corn steep liquor.

[0045] ② Preparation before inoculation

[0046] Clean the fermenter, assemble the thermometer, pH meter (corrected) and foam sensor, dissolve the fermentation medium in water, stir evenly, pour it into the fermenter, put in cooling water, sterilize, and correct the dissolved oxygen before sterilization DO is 0%, connect the air filter, and connect other ancillary equipment after cooling.

[0047] The composition of its fermentation medium is (g / L): glucose 200, yeast extract 20, corn steep liquor 10, MgSO 4 ·7H 2 O0.3, MnCl ...

example 2

[0056] ①Cultivation of seeds

[0057] Pick 1 yeast Saccharomyces cerevisiae NJWGYH30566 (CGMCCNo.4349) colony from the PDA plate, put it in a 500mL Erlenmeyer flask filled with 40mL of seed medium, and cultivate it in a shaker with a temperature of 30°C, a pH of 6.5, and a rotation speed of 180rpm for 36h. Obtain seed culture fluid;

[0058] The composition of the above seed medium is (g / L): 200 glucose, 16 yeast extract, and 4 corn steep liquor.

[0059] ② Preparation before inoculation

[0060] Clean the fermenter, assemble the thermometer, pH meter (corrected) and foam sensor, dissolve the fermentation medium in water, stir evenly, pour it into the fermenter, put in cooling water, sterilize, and correct the dissolved oxygen before sterilization DO is 0%, connect the air filter, and connect other ancillary equipment after cooling.

[0061] The composition of its fermentation medium is (g / L): glucose 250, yeast extract 25, corn steep liquor 15, MgSO 4 ·7H 2 O0.4, MnCl 2...

example 3

[0070] ①Cultivation of seeds

[0071] Pick 2 yeast Saccharomyces cerevisiae NJWGYH30566 (CGMCCNo.4349) colonies from the PDA plate and put them in a 500mL Erlenmeyer flask filled with 50mL of seed medium, and cultivate them in a shaker with a temperature of 35°C, a pH of 7.5, and a rotation speed of 200rpm for 30h. Obtain seed culture fluid;

[0072] The composition of the above-mentioned seed medium is (g / L): 250 glucose, 20 yeast extract, and 5 corn steep liquor.

[0073] ② Preparation before inoculation

[0074] Clean the fermenter, assemble the thermometer, pH meter (corrected) and foam sensor, dissolve the fermentation medium in water, stir evenly, pour it into the fermenter, put in cooling water, sterilize, and correct the dissolved oxygen before sterilization DO is 0%, connect the air filter, and connect other ancillary equipment after cooling.

[0075] The composition of its fermentation medium is (g / L): glucose 300, yeast extract 30, corn steep liquor 20, MgSO 4 ·...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com