Cambered surface cutting device for aluminum alloy frame

A technology of cutting device and aluminum alloy frame, which is applied to sawing machine devices, metal sawing equipment, attachment devices of sawing machines, etc., can solve the problems of affecting the cutting process, difficult to remove dregs, and unable to meet the needs of enterprises, so as to meet the needs of use. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

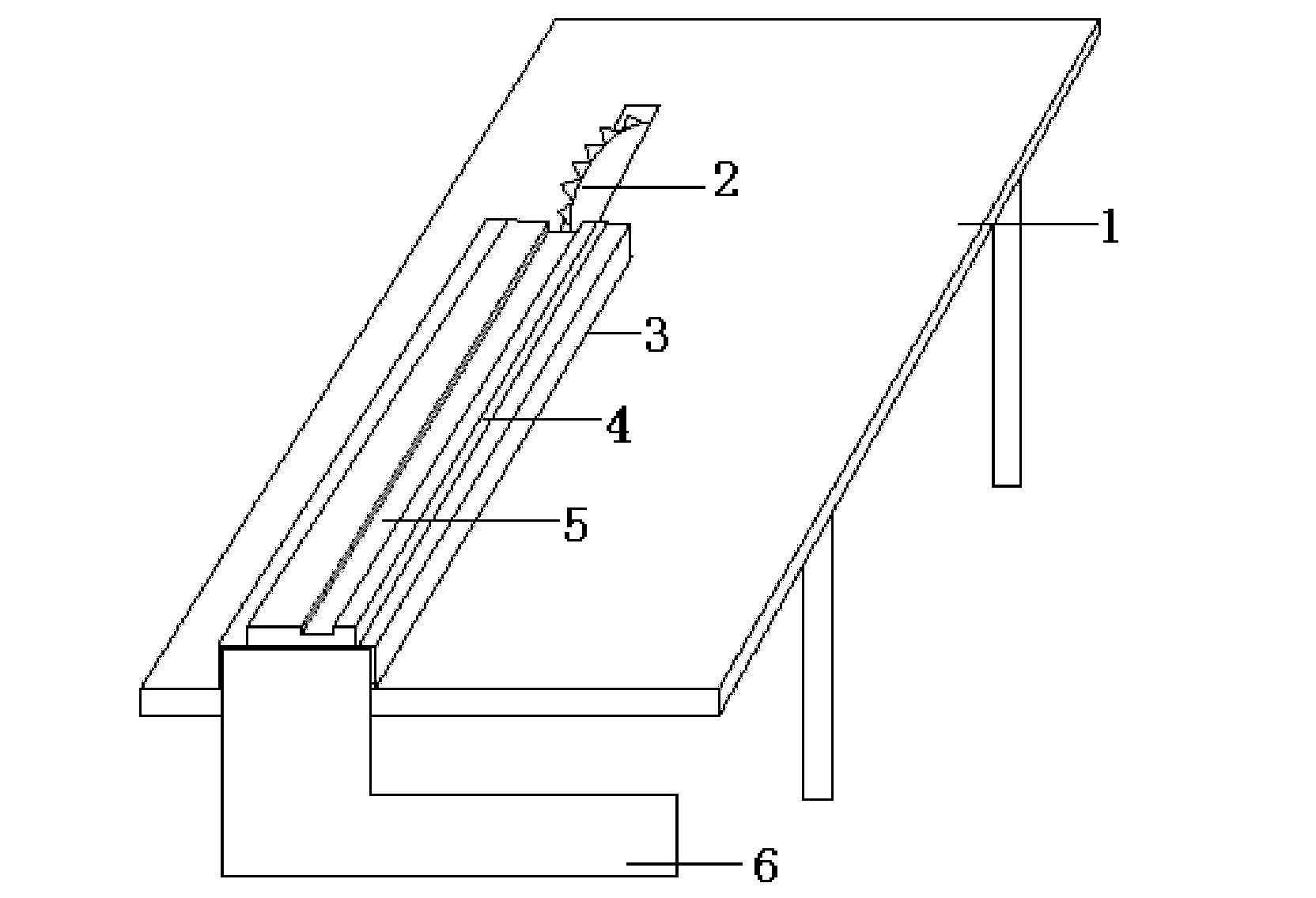

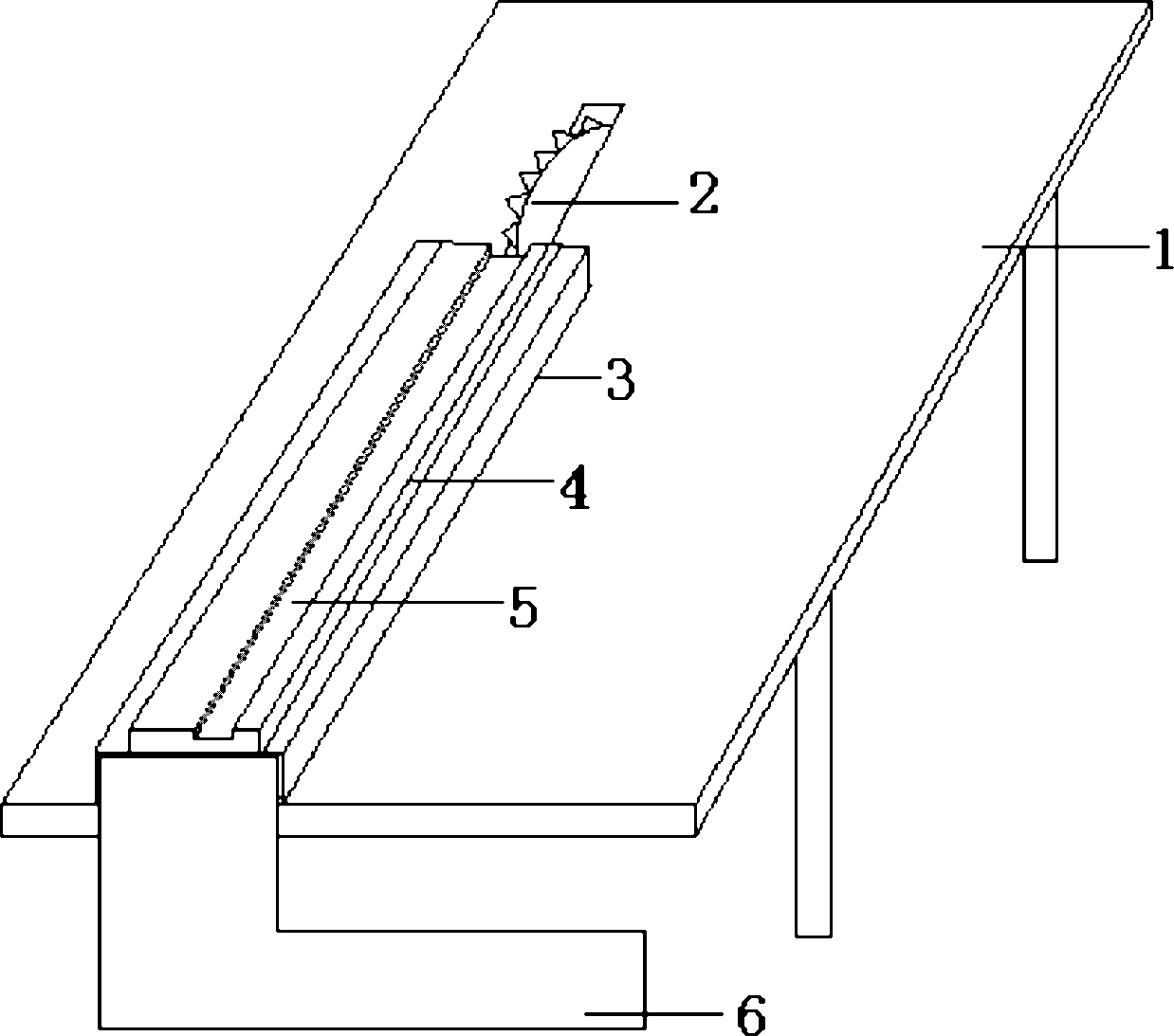

[0015] See attached picture.

[0016] An aluminum alloy frame arc surface cutting device includes a workbench 1, a disc saw 2 is installed under the workbench 1, and the disc saw 2 protrudes from a strip-shaped slot on the workbench 1, and on the workbench 1 A slag guide cylinder 3 is installed, and the slag guide cylinder 3 is located on one side of the disc saw 2, and a guide plate 4 is fixedly installed on the slag guide cylinder 3, and a guide groove 5 is provided in the middle of the guide plate 4, so that The guide groove 5 and the disc saw 2 are located on the same plane.

[0017] The height of the slag guide cylinder 3 is equal to the height at which the disc saw 2 protrudes from the workbench, and the rotation direction of the disc saw 2 is toward the slag guide cylinder 3 side.

[0018] The slag outlet end of the slag guide cylinder 3 is connected with an L-shaped slag guide pipe 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com