Linear guide rail locking device with protecting function

A linear guide, locking device technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of guide rail damage, small cylinder clamping force, inability to apply to medium and large machine tools, etc., to increase locking force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

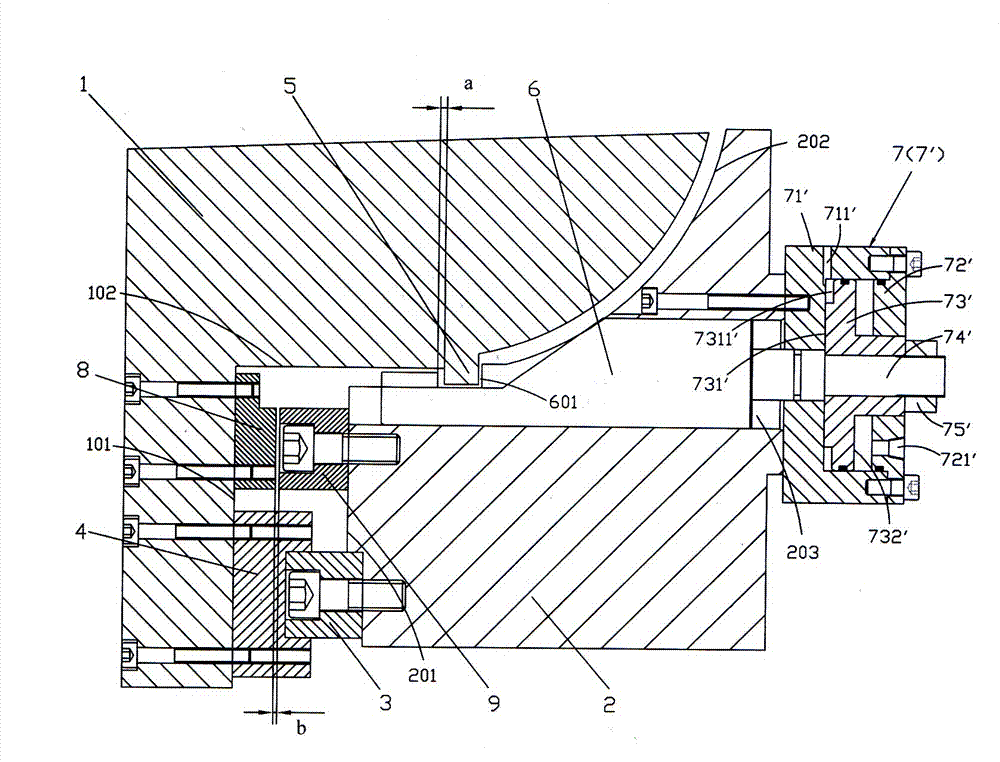

[0014] see figure 1 , a protective linear guide rail locking device of the present invention is arranged between the movable part 1 and the fixed part 2 of the machine tool, and the movable part 1 is slid on the linear guide rail 3 of the fixed part 2; wherein, the movable One side of the component 1 relative to the fixed component 2 is L-shaped, one side 101 is provided with a guide rail slider 4 that is fitted with the linear guide rail 3 of the fixed component 2, and the other side 102 is protruded along the length direction with a strip-shaped limit block or several limit blocks Block 5; the fixed part 2 is arranged on the side of the movable part 1 where the guide rail slider 4 is installed, and a side 201 corresponding to the guide rail slider 4 is provided with a linear guide rail 3 for the cooperation of the guide rail slider 4; the fixed part 2 is correspondingly movable A side 202 of the upper limit block 5 of the part 1 is provided with a plurality of through holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com