Guide wheel device for flexible guide rail

A technology of flexible guide rails and guide wheels, which is applied in metal processing and other directions, can solve the problems of limited application occasions of flexible guide rail devices, short load contact line, limited load transmission capacity, etc., to achieve improved stress conditions, small impact on accuracy, and high applicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

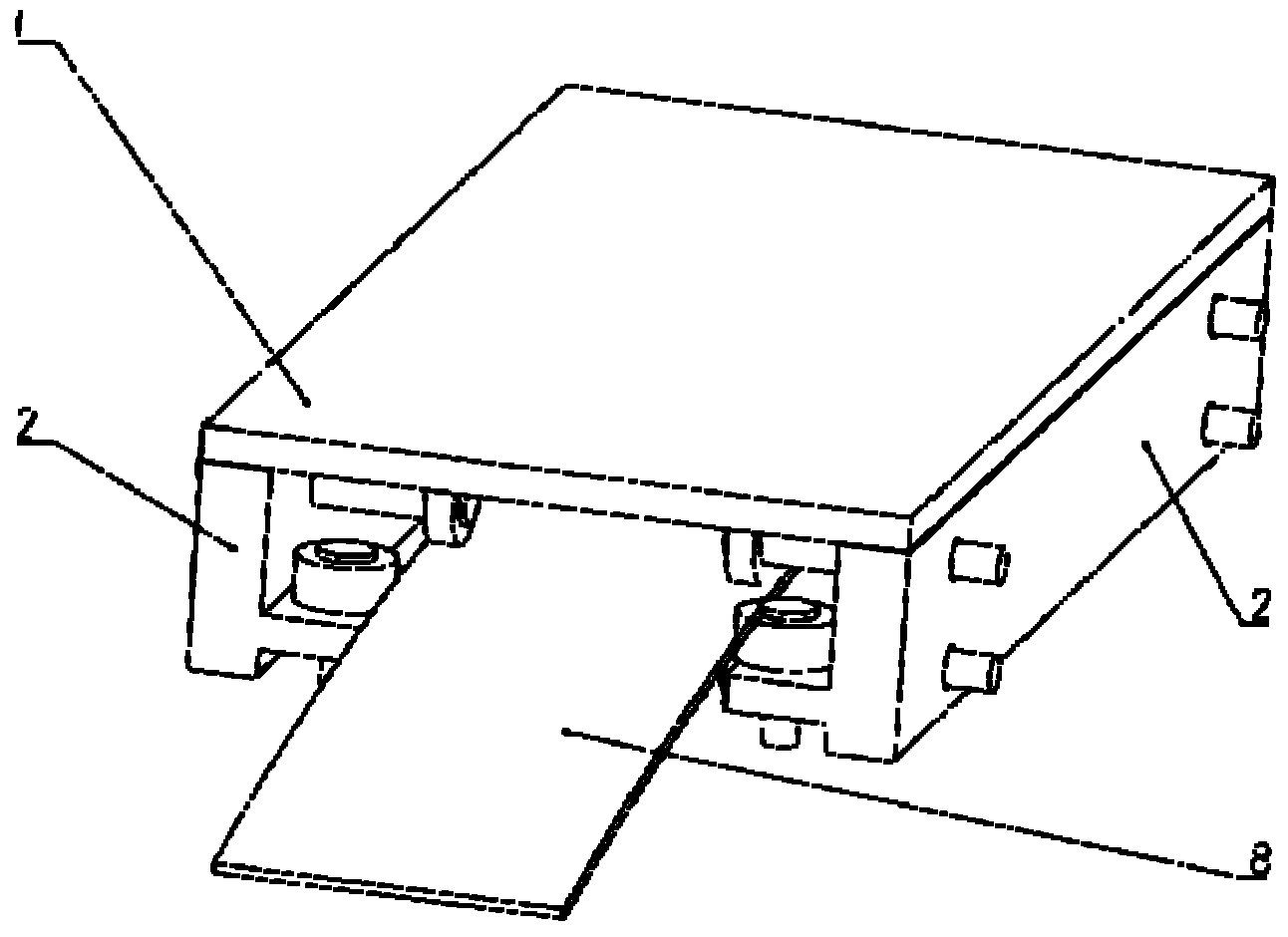

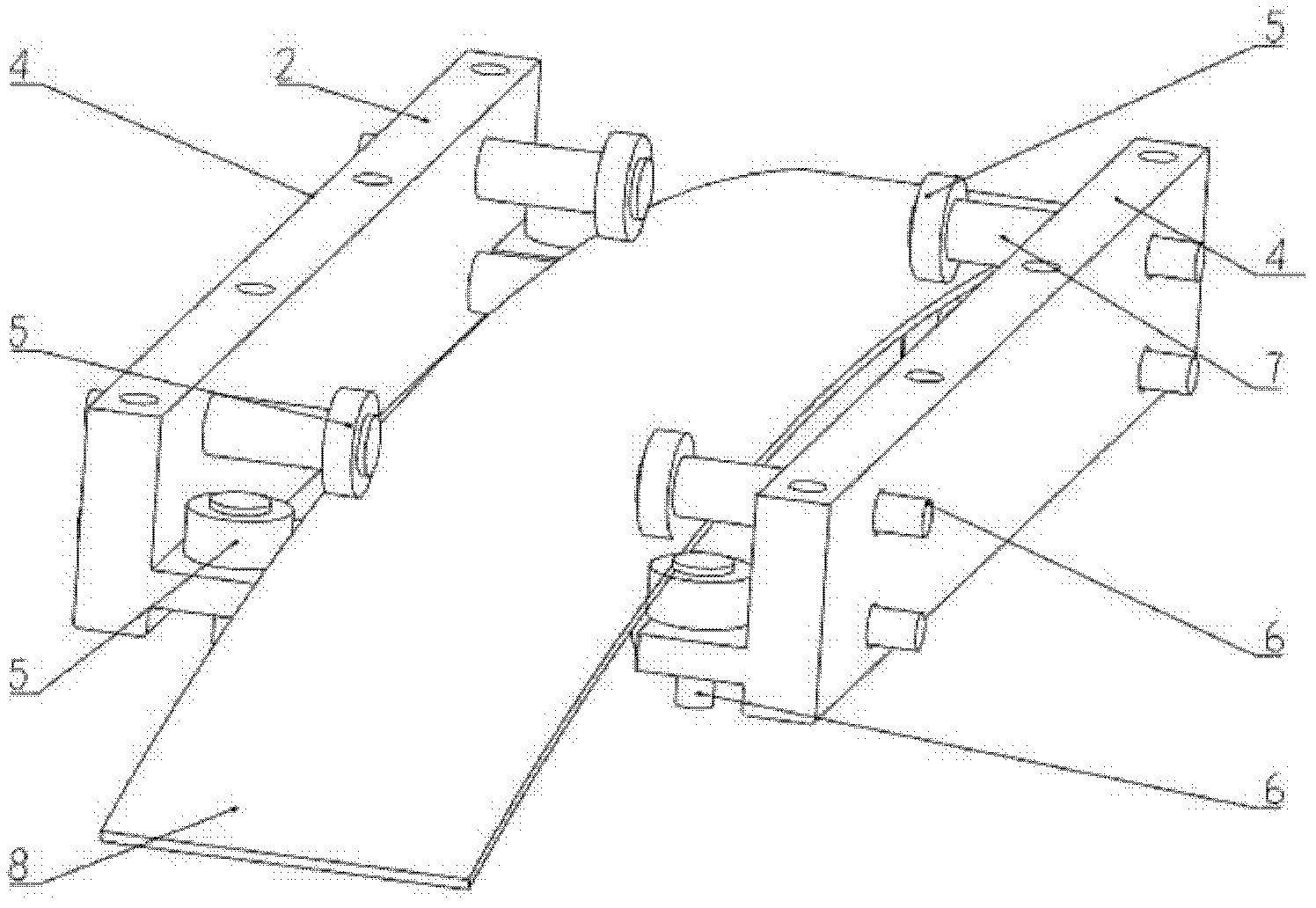

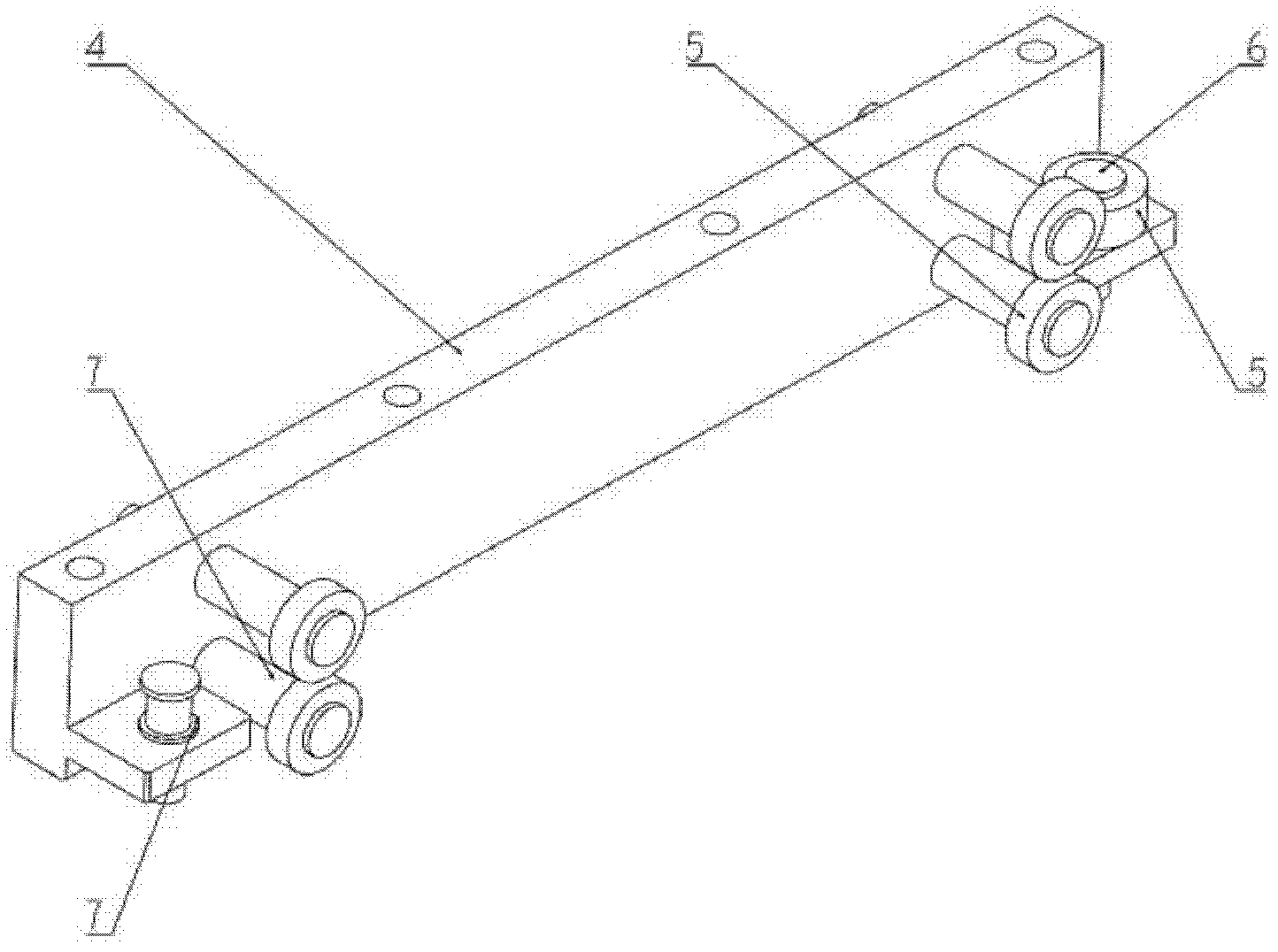

[0017] Such as figure 1 with figure 2 As shown, this embodiment is composed of two guide wheel mechanisms 2 arranged vertically and symmetrically below the guide rail span board 1. The guide wheel mechanism 2 includes: six sets of guide wheel modules 3 and guide wheel support plates 4, wherein: the guide wheel supports Three sets of guide wheel modules 3 are fixed at both ends of the plate 4 , and the guide wheel support plate 4 is vertically and fixedly connected with the guide rail spanning plate 1 .

[0018] The three sets of guide wheel modules 3 are respectively two sets of vertical arrangement and one set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com