Method for detecting dispersing uniformity of lithium ion battery slurry

A lithium-ion battery, evenly dispersed technology, applied in the preparation of test samples, material resistance, etc., can solve the problems of particle agglomeration, conductive agent agglomeration, inaccurate test results, etc., and achieve the effect of accurate and objective evaluation process

Inactive Publication Date: 2011-10-05

SHENZHEN BAK BATTERY CO LTD

View PDF3 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

While improving the rate performance of lithium iron phosphate materials, these measures have brought another new problem: the dispersion of lithium iron phosphate slurry

Coating carbon, adding more conductive agents, and material particles with smaller particle sizes all make it difficult to disperse the lithium iron phosphate slurry evenly during the preparation process, and particle agglomeration and conductive agent agglomeration may occur.

The consistency of the pole piece coated with such a slurry is very poor, which causes the internal resistance of the battery to be inconsistent, which in turn affects the performance of the battery.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

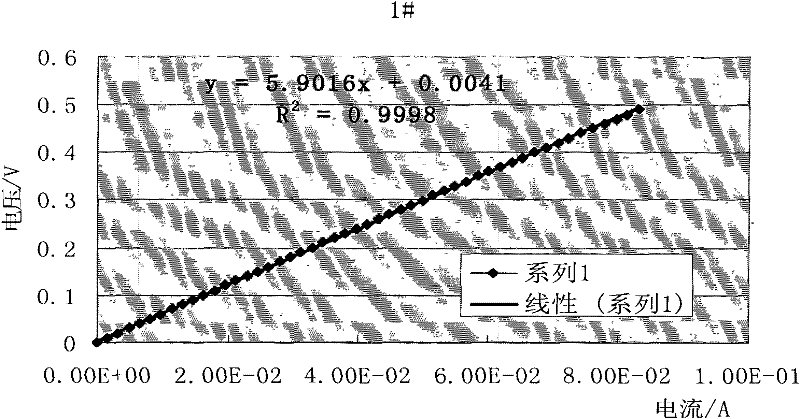

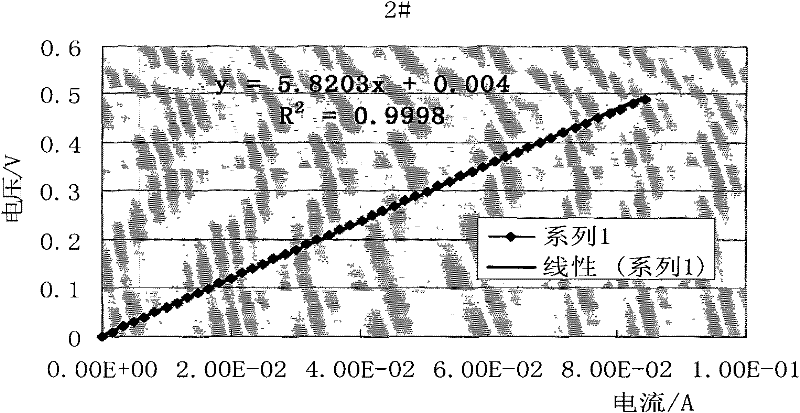

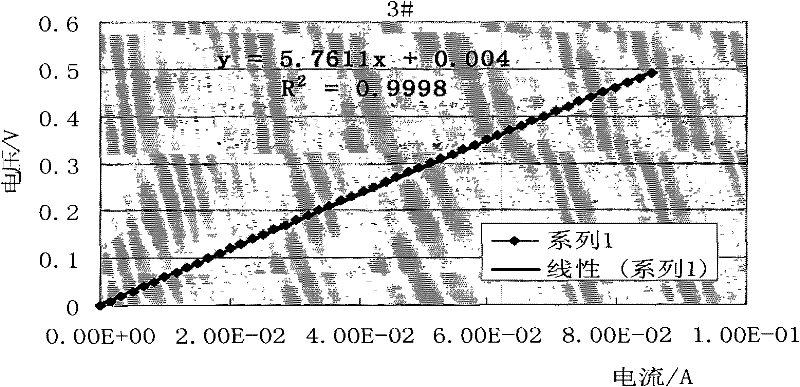

[0021] It is used to evaluate the dispersion uniformity of the positive electrode lithium iron phosphate slurry of a certain power type battery. Take slurry from the upper, middle and lower layers of the center of the slurry tank, and prepare samples according to steps 1 to 3 of the above method. The sample data are as follows:

[0022] Sample serial number

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for detecting dispersing uniformity of lithium ion battery slurry. The method comprises the following steps of: sampling different positions of the slurry; detecting electrical conductivity of the sample; and evaluating the dispersing uniformity of the slurry according to difference of the electrical conductivity of the sample. A novel method for evaluating the dispersing uniformity of the slurry is provided from a special angle. According to the method in the invention, the dispersing uniformity of the slurry is converted from the electrical conductivity to electric conductance with a balanced amount so that the process of evaluating the dispersity of the slurry is exacter and more objective.

Description

technical field [0001] The invention relates to the field of manufacturing lithium ion batteries, in particular to a method for detecting the dispersion uniformity of slurry of lithium ion batteries. Background technique [0002] The characteristics of high safety and long cycle life of lithium iron phosphate battery have made it a hot spot in the development of cathode materials for lithium-ion power batteries in recent years. However, the conductivity of the lithium iron phosphate material itself is very poor, and its conductivity is 6 to 7 orders of magnitude lower than that of traditional materials such as lithium cobalt oxide. In the development of power lithium-ion power batteries, it is required to have excellent rate charge and discharge performance. In response to this, current lithium iron phosphate materials generally improve their own conductivity by surface coating or metal ion doping, reducing the primary particle and secondary agglomeration particle size, or ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N27/04G01N1/28

Inventor 曹明元相江峰杨闯孔瑞张家玮刘家林谢彩霞

Owner SHENZHEN BAK BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com