Concentration technology of cyclohexanone saponification spent lye

A waste lye, cyclohexanone technology, applied in chemical instruments and methods, heating water/sewage treatment, natural water treatment, etc., can solve problems such as high energy consumption, foaming, blocked pipes, etc. Low power consumption and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

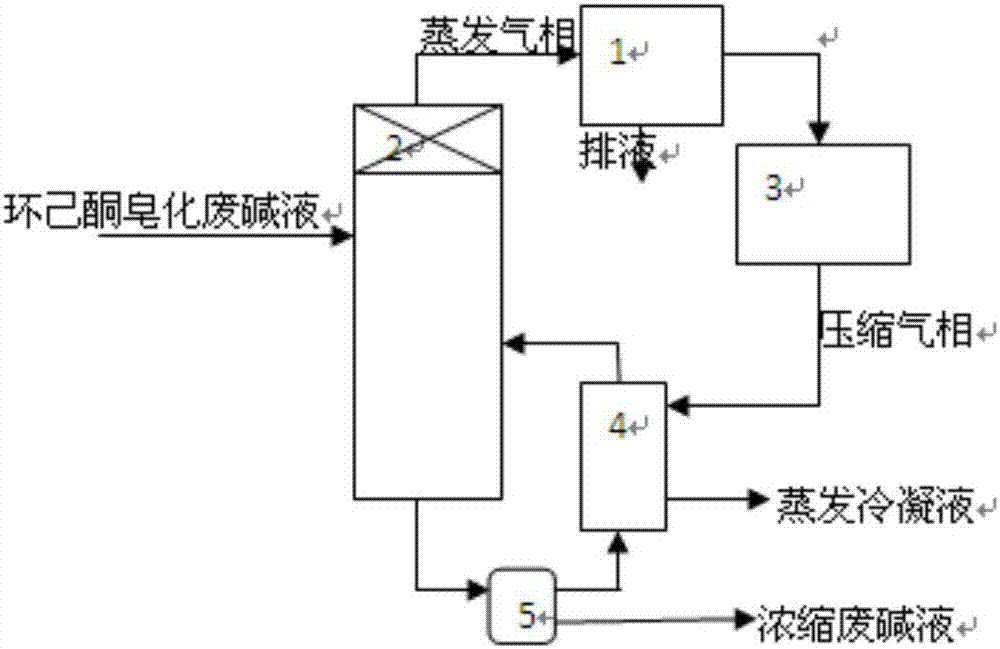

Image

Examples

Embodiment 1

[0028] 10t / h cyclohexanone saponification spent caustic liquor (solid substance content is 30%) enters the spent caustic evaporating tower 2 through pressure difference, evaporates in the spent caustic evaporating tower 2, and the evaporated gas phase at 95-100°C passes through the liquid cyclone separator 1. Cycling and liquid separation, and then the gas phase enters the Roots compressor 3 and then compressed. The temperature of the gas phase at the outlet of the Roots compressor 3 is 105-115 ° C. The compressed gas phase is used as a heat source to heat and evaporate the cyclohexanone saponification waste in the waste alkali evaporation tower 2. Alkali, compressed gas phase is condensed into liquid in circulation pump 4.

[0029] The amount of liquid discharged from the hydrocyclone 1 and the circulating pump 4 is 4t / h, the power consumption of the Roots compressor 3 is 350Kw / h, and the solid content of the concentrated cyclohexanone saponification waste lye is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com