Device for measuring a capacitance variation in a variable capacity structure

A variable capacitance and capacitive technology, which is applied in the direction of transmitting sensing components, electronic switches, electrical components, etc. by using electric/magnetic devices, can solve problems such as detection being delayed for too long and sensor accuracy decreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

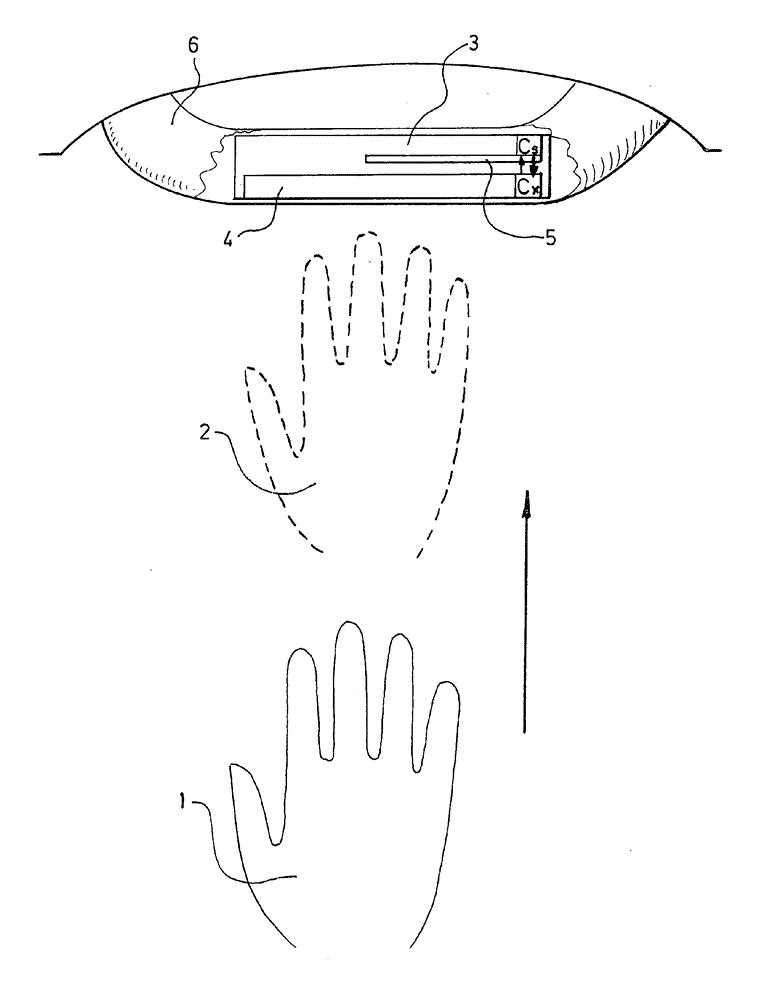

[0061] As shown in FIG. 2, the charge transfer capacitive sensor 3 incorporated into the vehicle door handle 6 includes a capacitor C x The changed electrode 4 and the reference capacitance C located on the printed circuit board 5 S , The latter is also incorporated into the handle 6. When the driver's hand approaches the door handle 6 from the far position 1 to the near position 2 (Figure 2), the capacitance of the electrode C X Increased amount ΔC X , Using the reference capacitor C located on the printed circuit board 5 connected to the electrode 4 S To measure this change ΔC X . If this capacitance exceeds the threshold, it means that the driver's hand is located at position 2 near the handle of the door, and the driver wants to open the door.

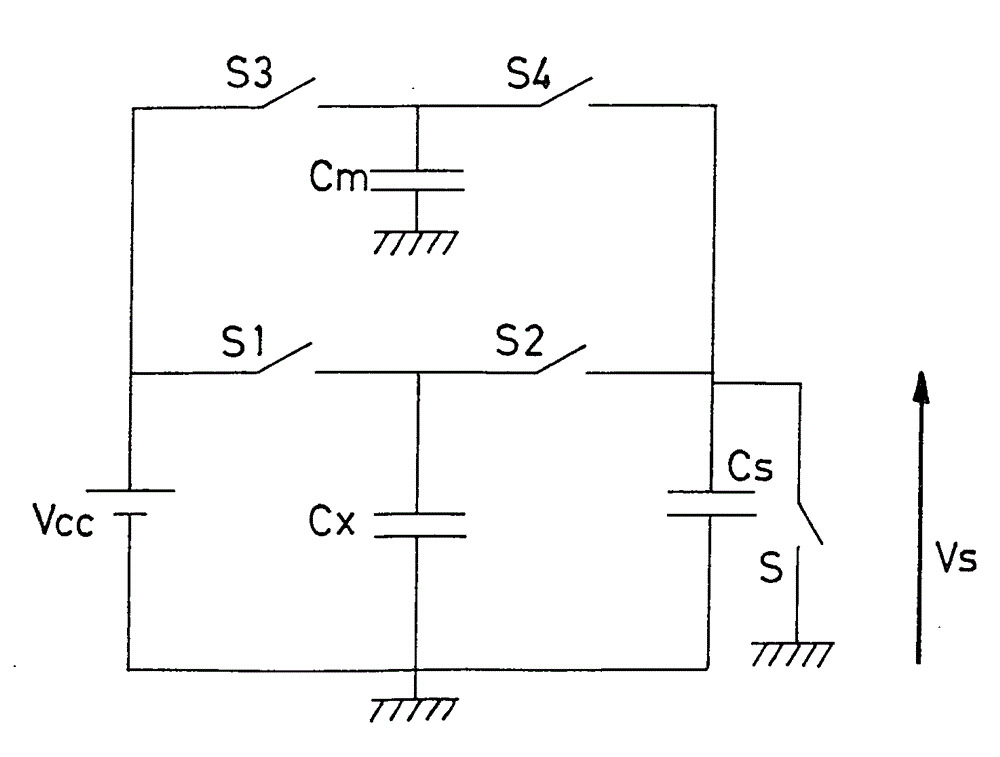

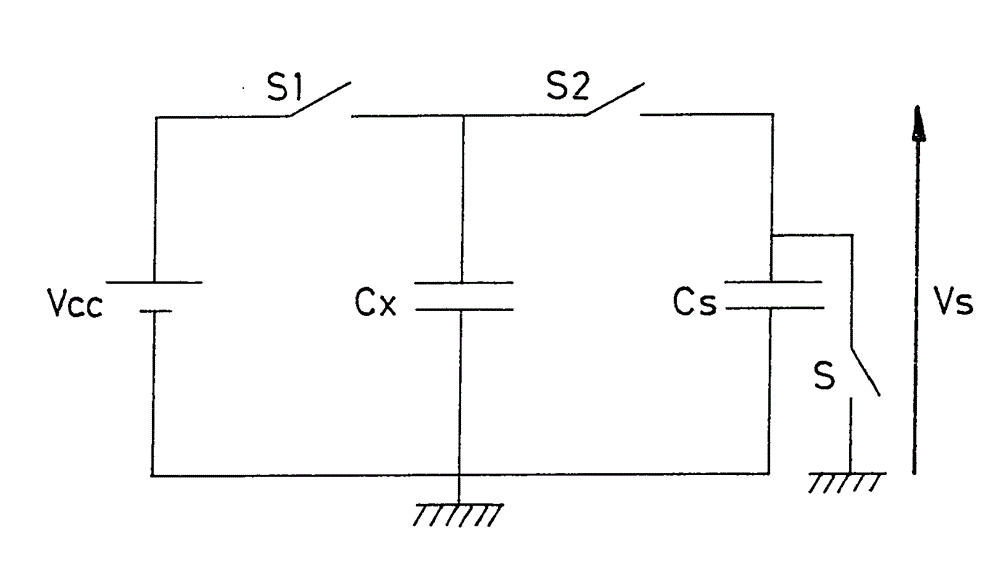

[0062] The prior art (shown in FIG. 1) describes a capacitive sensor that measures the change in capacitance of a variable capacitance, and is implemented by making the capacitance C of the electrode X Charge and discharge to reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com