Washing tower

A technology of washing tower and washing liquid, which is applied in the direction of using liquid separation agent, combined device, and separation of dispersed particles, which can solve the problems of turbulent air flow and strong air flow, and achieve the effects of prolonging service life, reducing pollution problems, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

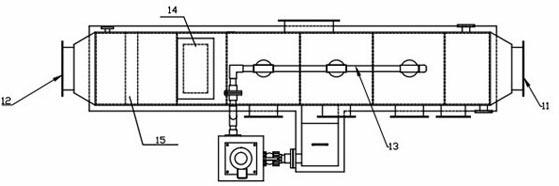

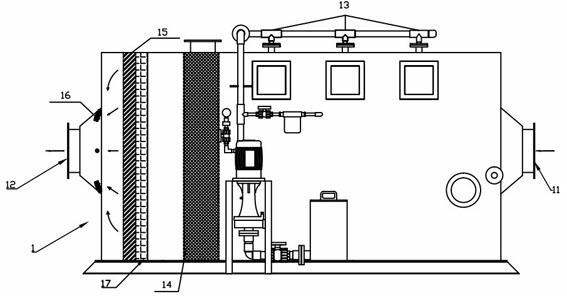

[0020] This example is aimed at figure 1 The horizontal scrubber shown is modified as figure 2 It can be seen from the schematic diagram of the structure that the main body of the washing tower is a hollow cavity 1, and the cavity 1 has an air inlet 11 and an exhaust port 12 following the airflow direction, and between the air inlet 11 and the exhaust port 12 The packing filter layer, the washing liquid spray group 13, the defogging layer 14 and the plate-and-frame filter structure are provided in sequence, wherein the filler filter layer, the defogging layer 14 and the plate-frame filter structure respectively fill the entire airflow channel of the cavity. In particular, the plate and frame filter structure is a composite structure of an aluminum honeycomb filter 17, an activated carbon filter 15, and a diversion atomization layer 16. The filter screen 15 is evenly arranged with diversion holes, and the surface is coated with an ozone catalyst. Its main function is to rect...

Embodiment 2

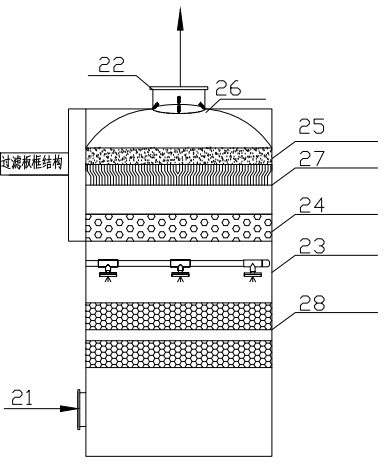

[0026] like image 3 Shown is a schematic structural view of another embodiment of the present invention. It is not difficult to find from the diagram that this embodiment is applied to vertical scrubbers, even multi-stage cascaded vertical scrubbers. From the perspective of the structure of a single vertical washing tower, it is roughly the same as the internal structure composition of Embodiment 1. The difference lies in the difference in the direction of the airflow caused by the different positions of the air inlet and the air outlet, and the difference in the relative direction of the airflow direction and the mutual impact of the washing liquid spray group. But judging from the results: the turbulent flow formed by the airflow in the inner cavity of the scrubber always exists, and the rectification effect of the aluminum honeycomb filter is also required.

[0027] From the specific implementation of this embodiment: the filter frame structure in this embodiment is a co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap