Liquid ejecting head, liquid ejecting head unit, and liquid ejecting apparatus

一种液体喷射头、喷射装置的技术,应用在液体喷射装置,喷墨式记录装置领域,能够解决阻碍压电元件变位、间隔壁刚性下降、着墨位置偏移等问题,达到抑制着墨位置的偏移、提高打印质量、抑制电压下降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

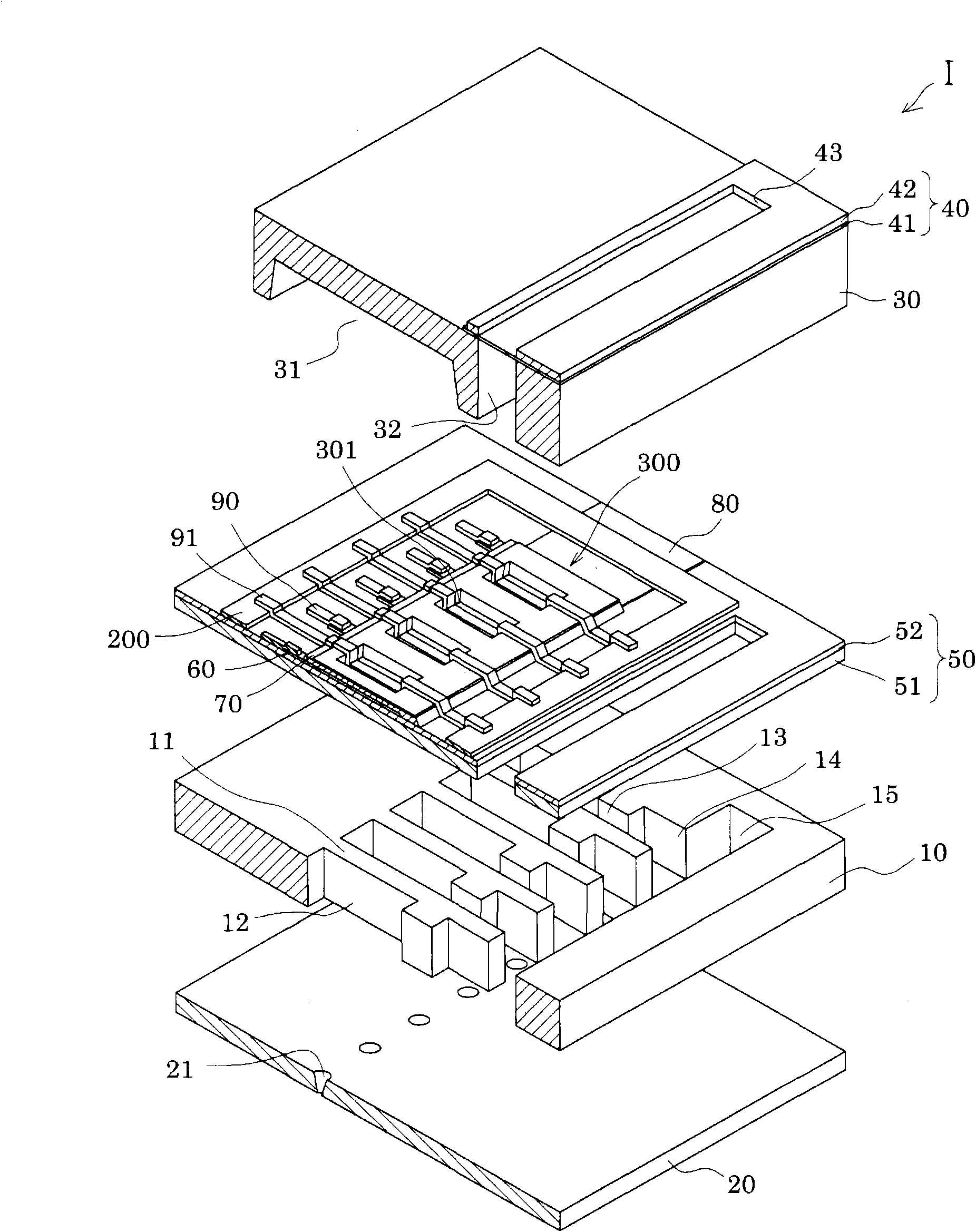

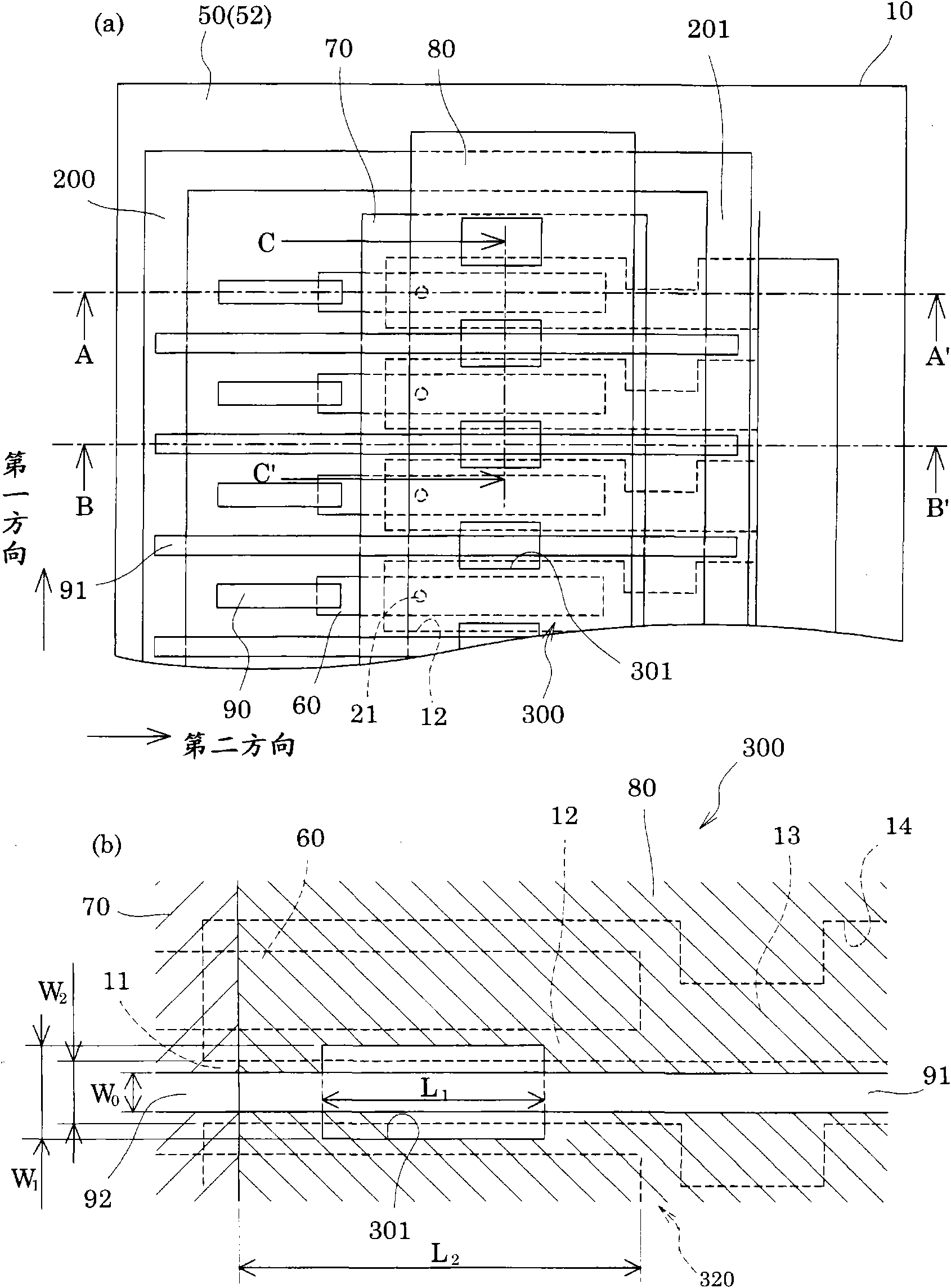

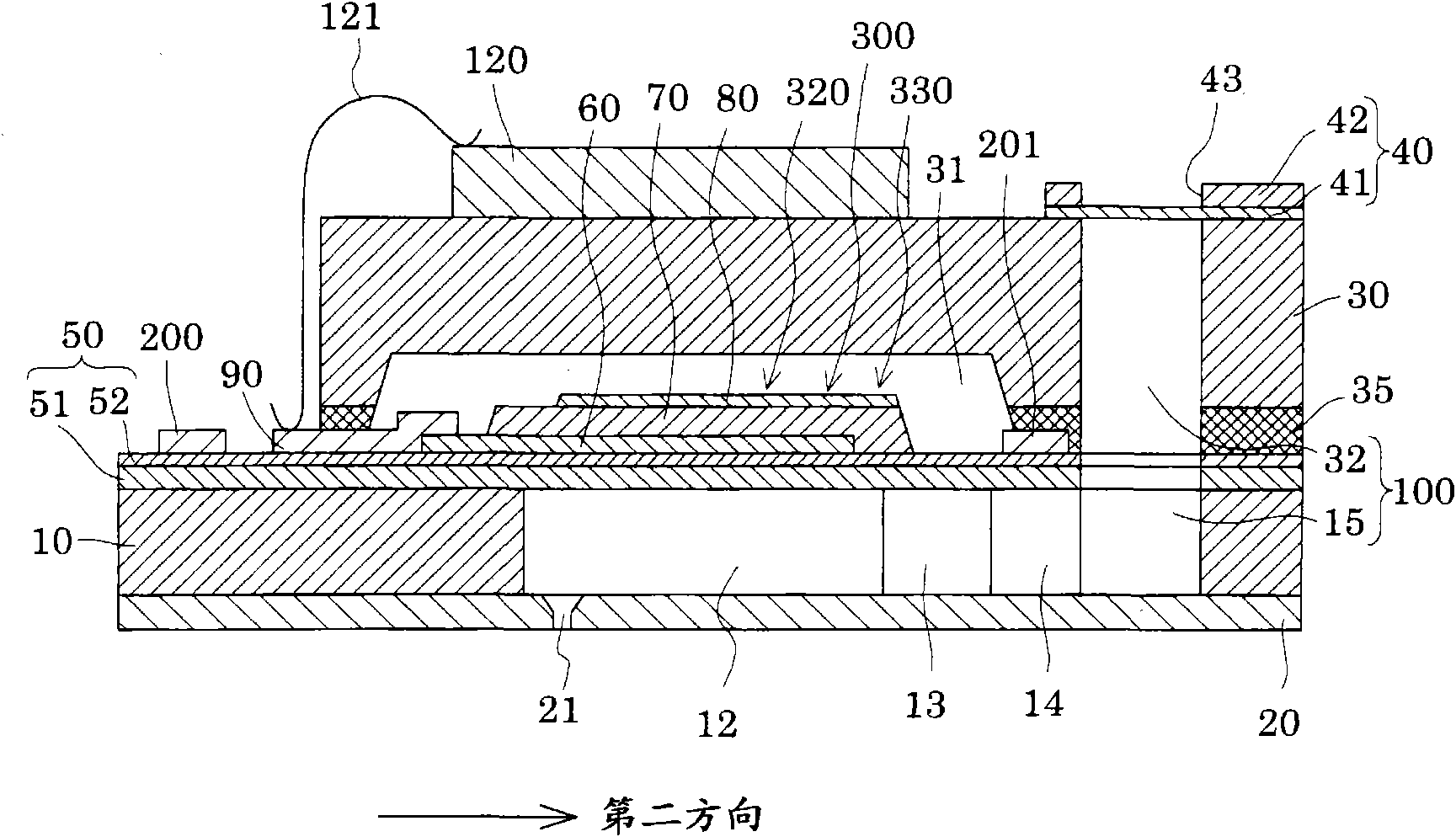

[0030] figure 1 It is an exploded perspective view of an ink jet recording head as an example of a liquid ejection head according to Embodiment 1 of the present invention, figure 2 It is a plan view and an enlarged view of main parts of the flow path forming substrate of the inkjet recording head, image 3 is along figure 2 A cross-sectional view of the line A-A', Figure 4 is along figure 2 The sectional view of the B-B' line, Figure 5 is along figure 2 The cross-sectional view of the line C-C'.

[0031] Such as figure 1 As shown, a plurality of pressure generating chambers 12 partitioned by partition walls 11 are arranged along the width direction (short side direction, the first direction in this embodiment) on the flow path forming substrate 10 constituting the inkjet recording head 1. In addition, ink supply channels 13 and communication channels 14 that communicate with the respective pressure generating chambers 12 are provided on the flow channel forming subs...

Embodiment approach 2

[0060] Figure 6 It is a plan view of main parts of an ink jet recording head as an example of a liquid ejecting head according to Embodiment 2 of the present invention. In addition, the same reference numerals are assigned to the same components as in the first embodiment described above, and overlapping descriptions will be omitted.

[0061] Such as Figure 6 As shown, in the present embodiment, the common lead electrode 91A includes a narrow portion 92 and a wide portion 93, the narrow portion 92 is provided in the opening 301 with a width narrower than the thickness of the partition wall 11, and the wide portion 93 is provided in the opening 301. The outer side of the opening 301 is provided with a width wider than the thickness of the partition wall 11 .

[0062] Thus, by providing the narrow portion 92 on the common lead electrode 91A, it is possible to prevent the common lead electrode 91A from obstructing the displacement of the piezoelectric body active part 320 (vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com