Automatic soft hood coverage system

A soft canopy and automatic technology, applied in the direction of load coverage, motor vehicles, vehicles used for freight, etc., can solve the problems of narrow application range, low degree of automation, leaking, etc., and achieve wide application range, simple structure, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

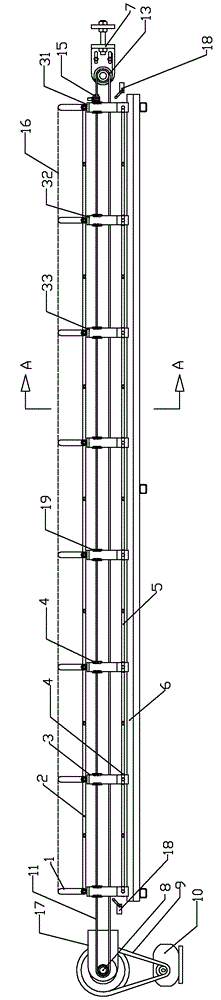

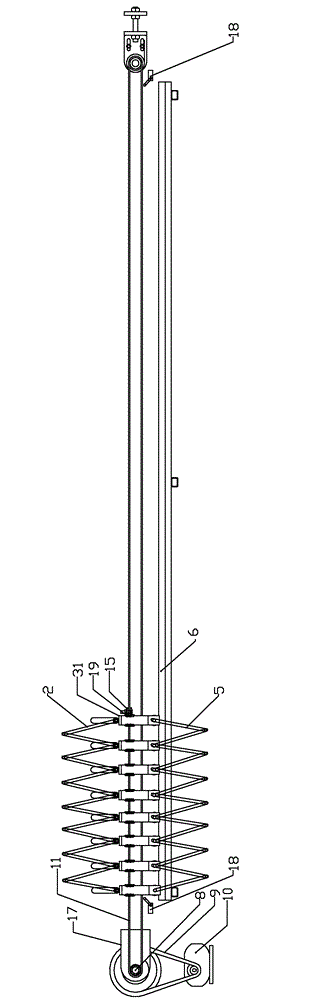

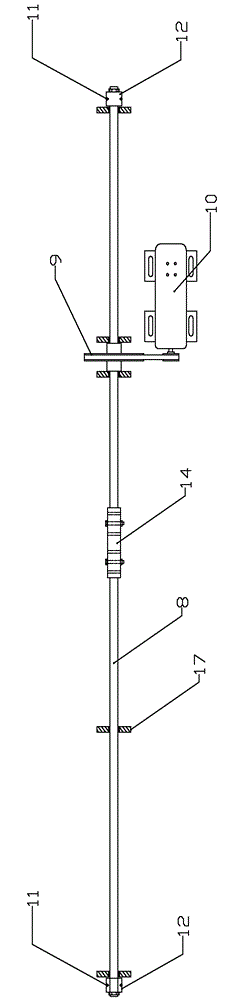

[0031] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an automatic soft tent covering system includes a guide rail 6, a motor 10 and a soft tent cover 16. There are two guide rails 6, and each guide rail 6 in this embodiment uses eight supporting frames 3 to support The frame 3 is connected with the guide rail 6 through the roller 4; the upper end between every two support frames 3 on the same guide rail 6 is connected with an upper movable link 2, and is located between every two support frames 3 on the same guide rail 6 The lower end of the lower end is connected with the lower movable link 5; the upper movable link 2 between the above-mentioned every two support frames 3 is divided into two sections, and the two sections are hinged; the lower movable link between the above-mentioned e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com