Corner roller for ribbon conveyer bending device

A technology of belt conveyor and turning device, applied in the direction of conveyor, transportation and packaging, can solve the problems of friction damage of conveyor belt and large local stress of conveyor belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

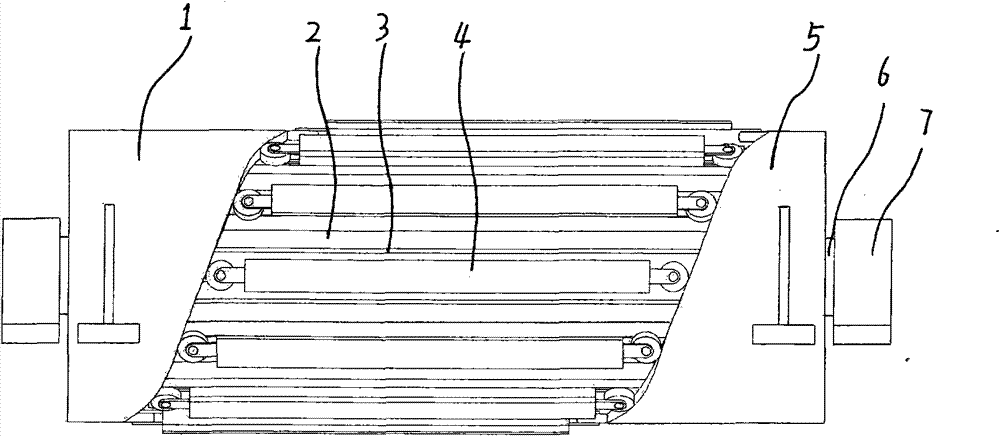

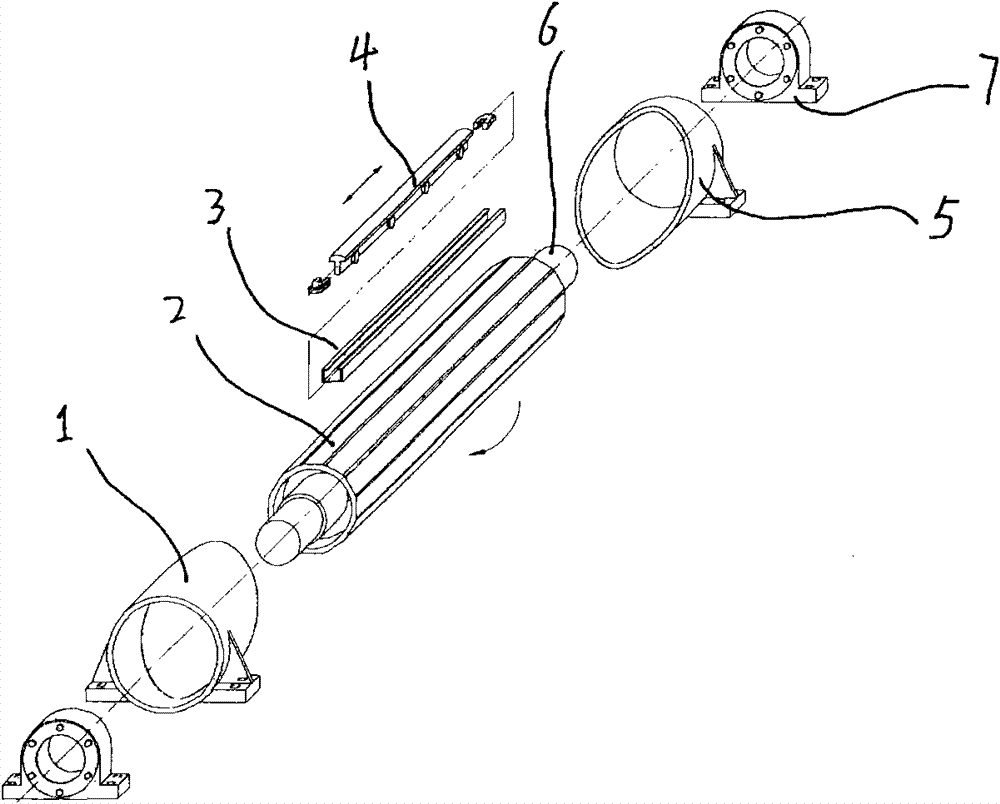

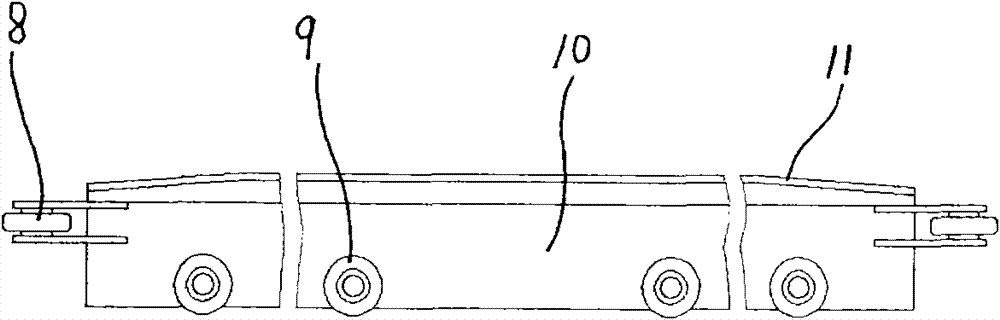

[0012] Depend on figure 1 , figure 2 , image 3 It can be seen that the present invention includes: left cylindrical cam 1, rotating drum 2, guide rail 3, conveyor belt support 4, right cylindrical cam 5, rotating shaft 6, shaft seat 7, rotating shaft 6 penetrates and is arranged in the shaft seat 7 at both ends, The rotating shaft can rotate in the shaft seat. A rotating drum 2 is fixedly arranged on the rotating shaft 6, and the rotating shaft rotates coaxially with the rotating drum. A number of guide rails 3 are evenly spaced in the axial direction around the surface of the rotating drum 2, and a conveyor belt support 4 is provided in the guide rail 3, and each guide rail 3 is fitted with a guide rail that can be parallel to the axis of the roller along the guide rail. Moving conveyor belt supports. The conveyor belt support is composed of guide rollers 8, support rollers 9, support body 10, and rubber layer 11. In order to ensure that the conveyor belt support 4 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com