Automatic analysis device

An automatic analysis device, technology of noise components, applied in the direction of analysis of materials, measurement devices, biological material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

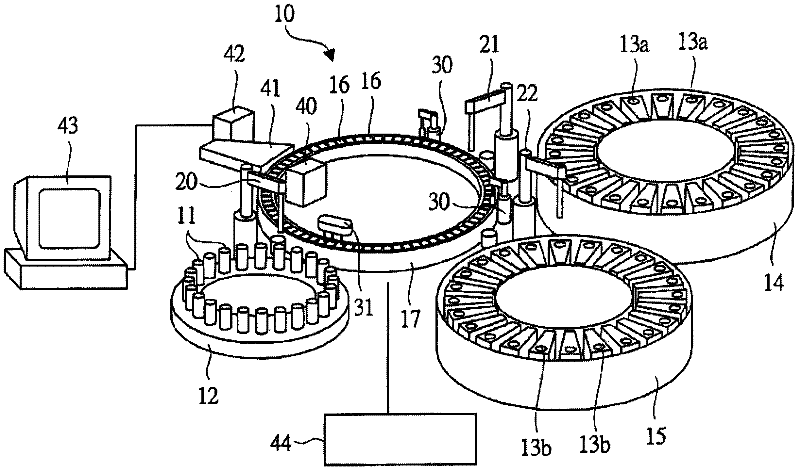

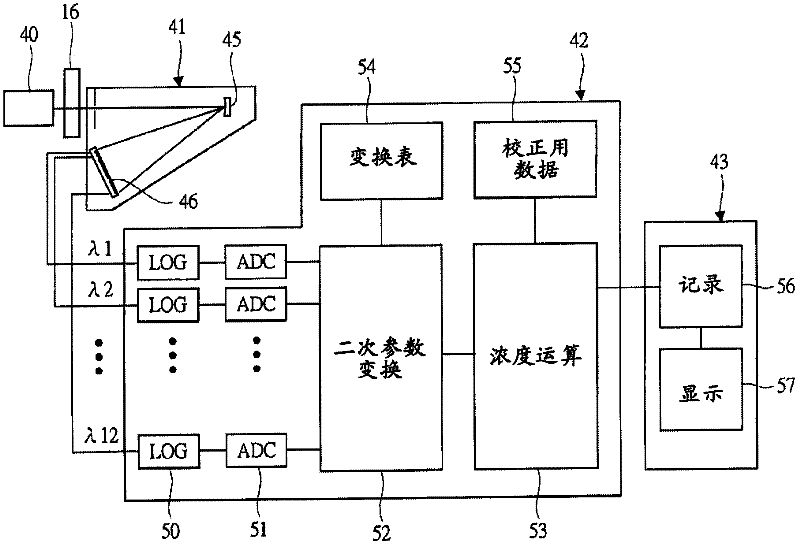

[0053] figure 1 It is a schematic perspective view showing the outline of one embodiment of the automatic analyzer of the present invention. figure 2 is description figure 1 The structure explanatory diagram of the structure of the signal processing part of the automatic analysis device.

[0054] Such as figure 1 As shown, the automatic analysis device 10 has a sample disk 12 that can be loaded with a plurality of sample containers 11 that hold samples; a first sample that can be loaded with a plurality of reagent containers 13a, 13b that respectively hold a first reagent or a second reagent. The drug disk 14 and the second reagent disk 15; and the reaction disk 17 in which a plurality of reaction containers 16 are arranged along the circumferential direction.

[0055] A sample probe (sample probe) 20 for dispensing (discharging) the sample sucked from the sample container 11 into the reaction container 16 is provided between the reaction disk 17 and the sample disk 12 . ...

Embodiment approach 2

[0089] Embodiment 2 of the present invention is the same as Embodiment 1 except for the calculation method in the variable conversion unit 52 , so description of the same matters will be omitted as much as possible.

[0090] In Embodiment 2, the variable conversion unit 52 uses a function D(λ, λ12) defined by the difference between the absorbance ABS(λ) at each wavelength λ and the absorbance ABS(λ12) at the longest wavelength λ12, and a weighting function W(λ), gain function G(λ), and the quadratic parameter Pa2 are calculated as follows.

[0091] Pa2=W(λ1)G(λ1)D(λ1,λ12)+W(λ2)G(λ2)D(λ2,λ12)+...+W(λ11)G(λ11)D(λ11,λ12)

[0092] In the formula, let

[0093] D(λi, λj)=ABS(λi)-ABS(λj)

[0094] W(λ1)+W(λ2)+...+W(λ11)=1

[0095] G(λ1)=C·exp(kλ). C is a constant.

[0096] The value of W(λ) also depends on the absorbance, and changes such that the absorbance decreases at relatively large wavelengths and small wavelengths, and becomes large at wavelengths between the large and sma...

Embodiment

[0111] The present invention will be further described below based on the examples. In addition, these Examples do not limit this invention.

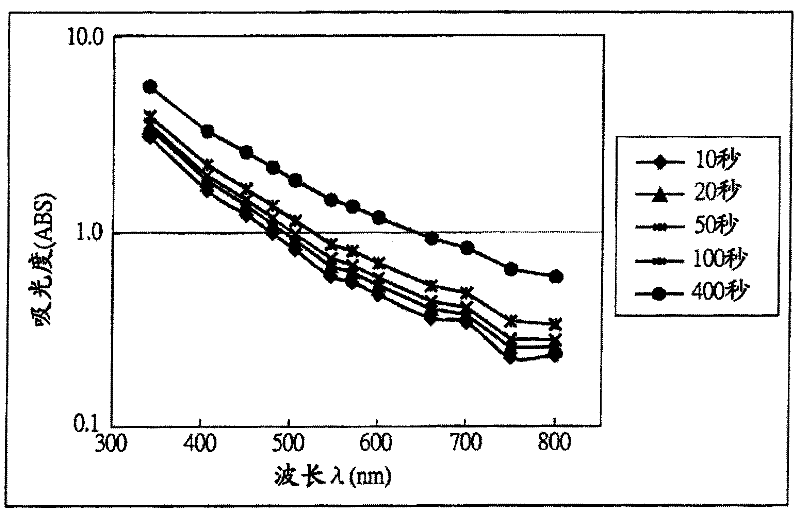

[0112] Figure 6 It is a graph plotting the analysis results of the conventional method and the method of Embodiment 1 by using Nanopia CRP of Sekisui Pharmaceutical Co., Ltd. as a reagent and administering a low concentration of CRP to the sample for control serum. The horizontal axis is the concentration of the sample, and the vertical axis is the analysis result. In the existing method, as the difference between the two wavelengths of the main wavelength of 570nm and the secondary wavelength of 800nm, the difference between the two measurements at 45 seconds and 300 seconds after the start of the reaction is used, and the known reagents with concentrations of 0mg / dL and 0.05mg / dL are used. The calibrated value of the sample was converted to the concentration.

[0113] In Embodiment 1, it is necessary to determine the value of k an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com