Low-concentration sampling nozzle binding apparatus

A sampling nozzle and low-concentration technology, applied in the field of hemming devices, can solve the problems of complicated operation process, uneven hemming, labor and time-consuming, etc., and achieve the effect of high hemming quality, high work efficiency and uniform hemming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

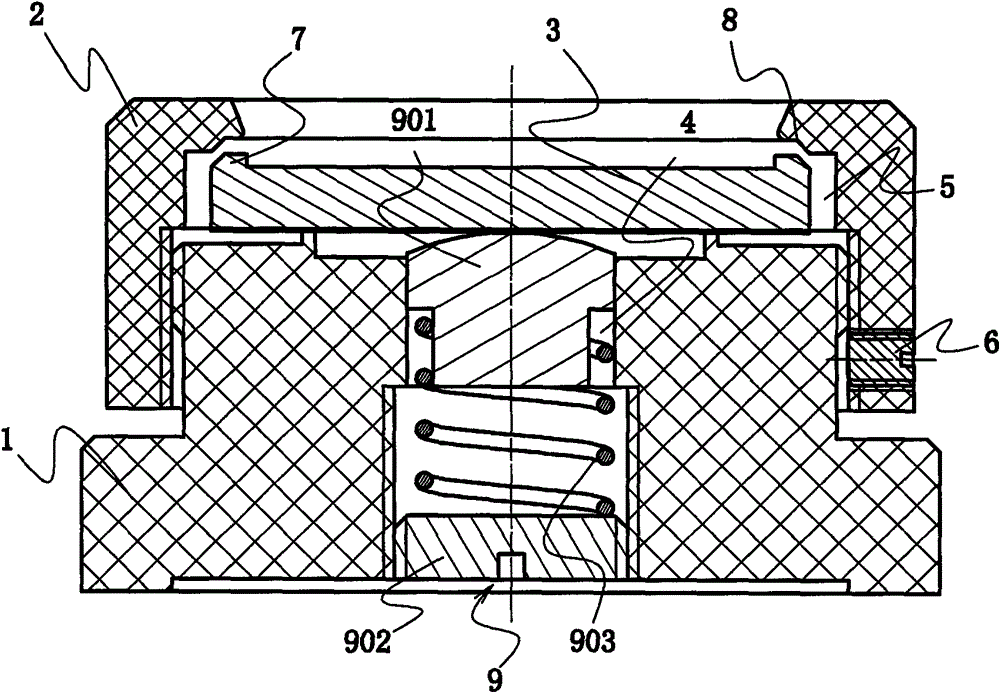

[0021] A low-concentration sampling nozzle roller, including a base 1 and a gland 2 fixed on the base 1, between the base 1 and the gland 2 is provided with a telescopic device 9 fixed in the base 1 to make vertical and horizontal Slider 3 with reciprocating motion.

[0022] The telescopic device 9 includes a plug 901, an adjustment nail 902, and a compression spring 903 arranged between the top 901 and the adjustment nail 902. One end of the compression spring 903 is set on the top 901, and the other end is in contact with the adjustment nail 902. The base 1 is provided with a placement groove 4 passing through the upper end surface and the lower end surface of the base 1 and communicating with the outside world. The telescopic device 9 is arranged in the placement groove 4 .

[0023] In the present invention, the gland 2 is an end cap with an L-shaped bottom end opening in section, the inner wall at one end of the gland 2 is provided with an internal thread, the outer wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com