Power tool

A technology of power tools and transmission parts, applied in the field of power tools, can solve the problems of complex structure, easy occurrence of danger, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention takes an electric circular saw as a preferred embodiment to specifically illustrate the shaft locking structure of a power tool.

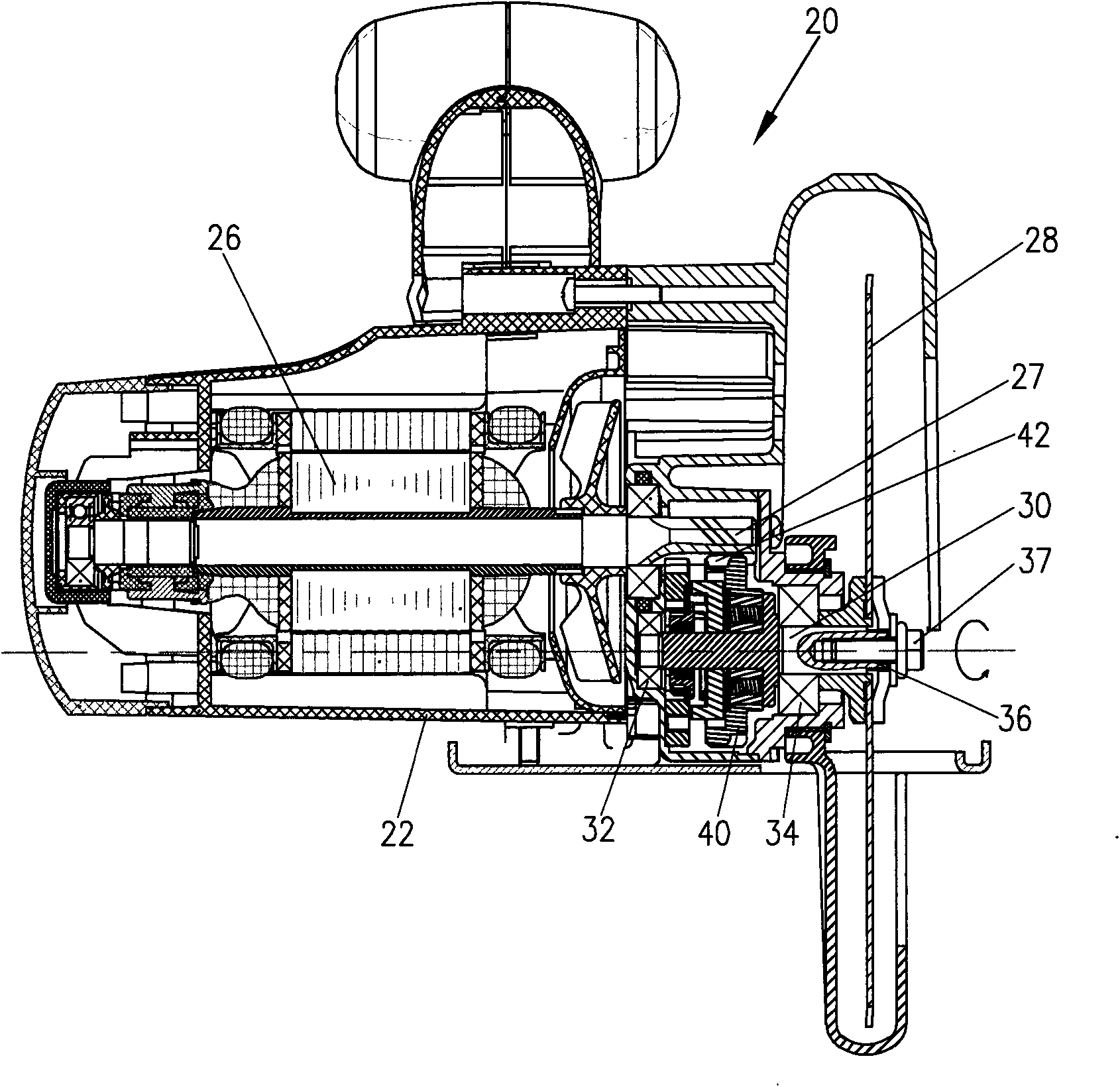

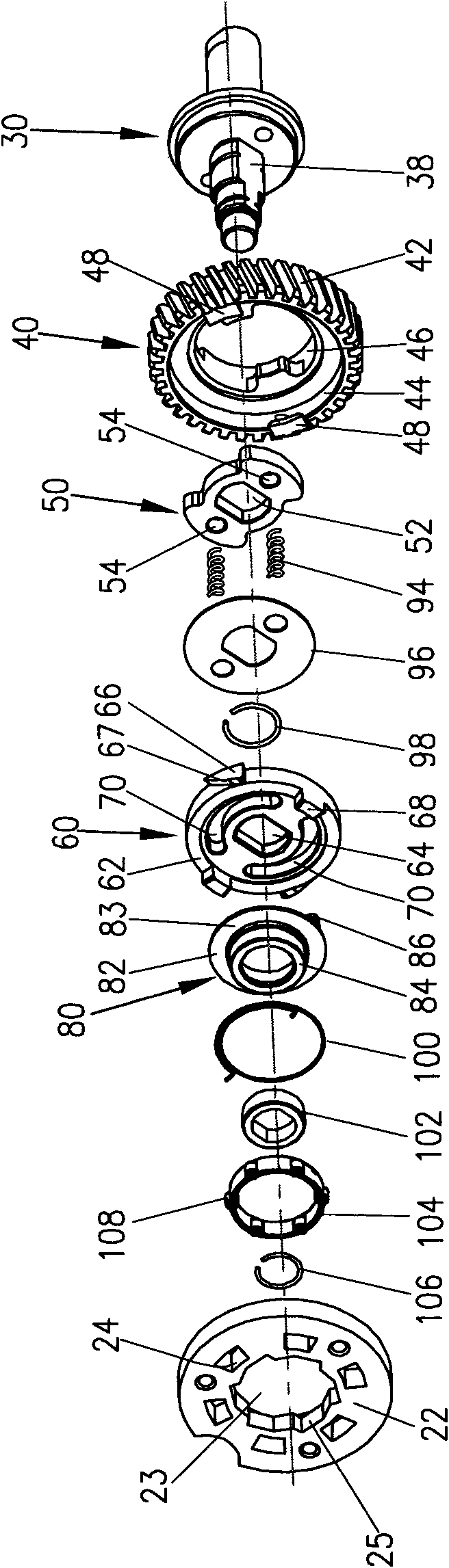

[0052] refer to figure 1As shown, the electric circular saw 20 in the first preferred embodiment of the present invention includes a casing 22, a motor 26 with a motor shaft 27 accommodated in the casing 22, an output shaft 30 connected to the saw blade 28, and the output shaft 30 The bearings 32, 34 are rotatably installed on the casing 22, and one end of the output shaft 30 is provided with a threaded hole 36 to be threadedly connected with the fastener 37 fixing the saw blade 28, and the other end is sleeved with a gear 40, and the outer end of the gear 40 The ring gear 42 meshes with the motor shaft 27 to transmit the rotational motion of the motor 26 to the output shaft 30 . In order to prevent the output shaft 30 from co-rotating when using tools such as a wrench to rotate the fastener 37 to disassemble the saw b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com