Movable type rotary hot-pressing production line for brake block die

A mobile, production-line technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of difficult to realize automatic loading and unloading operations, high labor intensity, low production efficiency, etc., achieve automatic loading and unloading operations, and ensure product quality. Quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

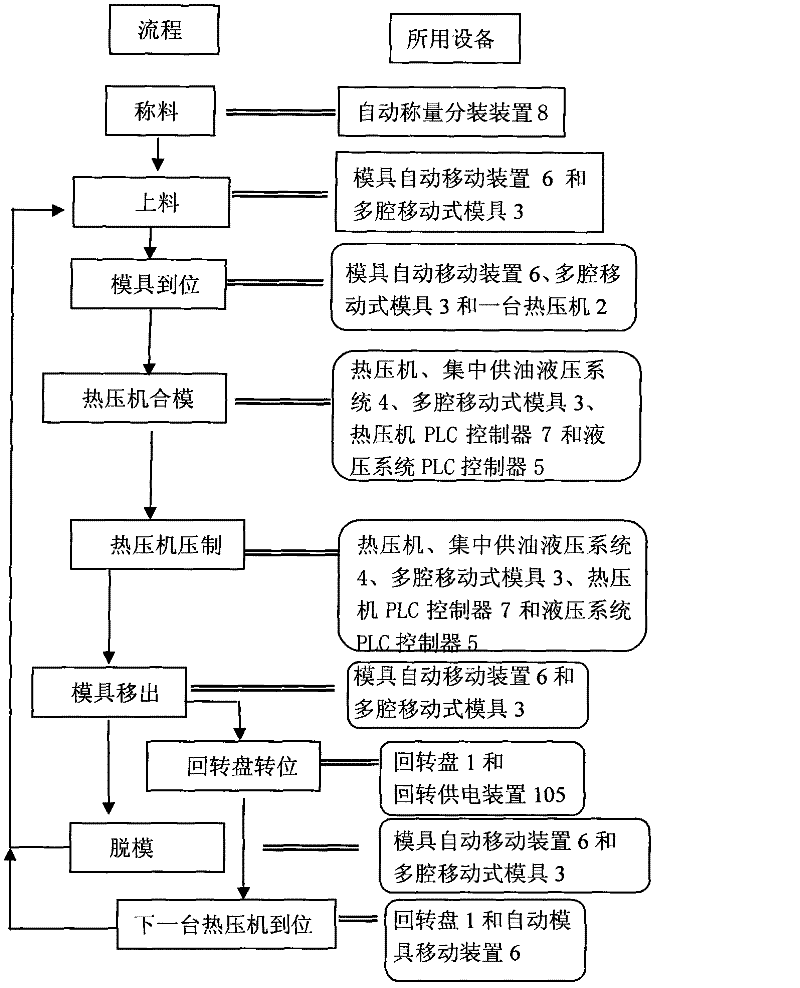

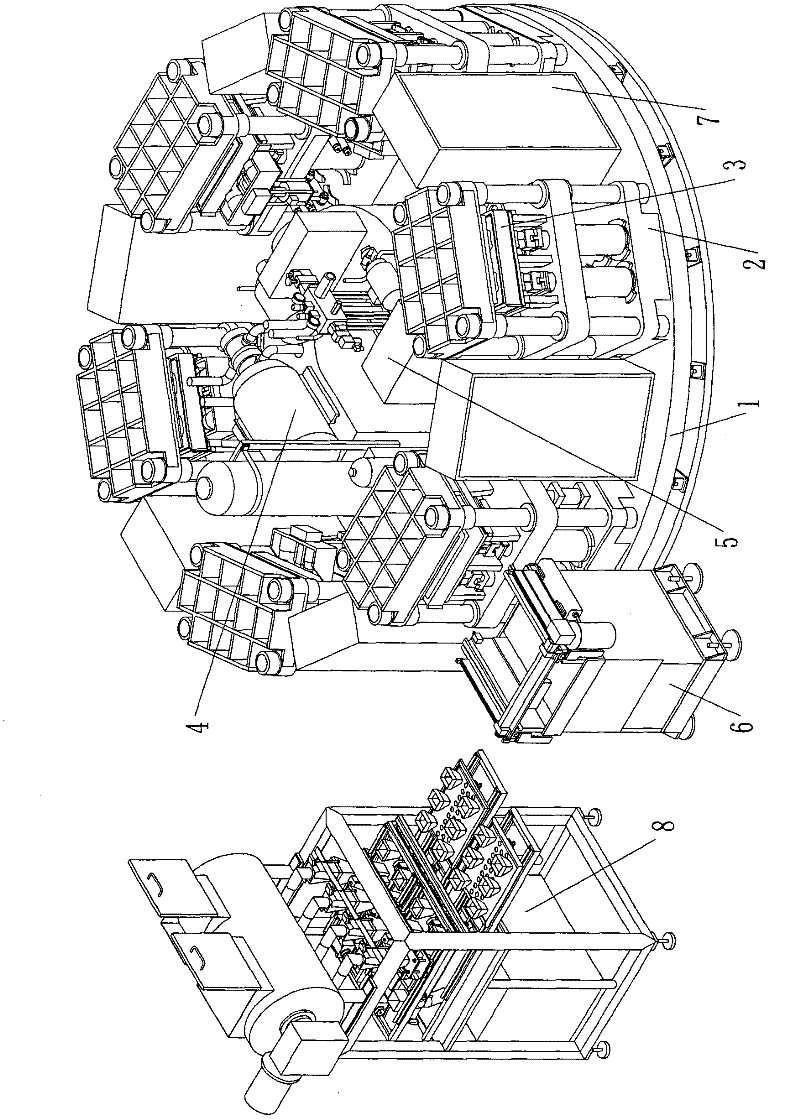

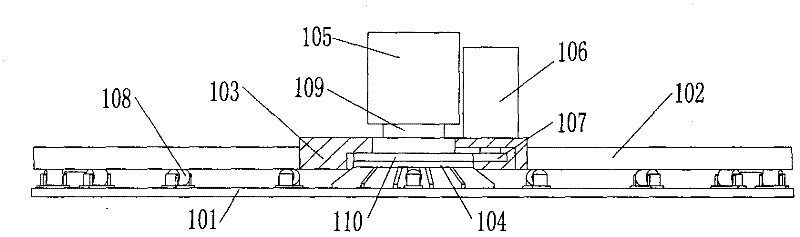

[0029] like figure 2 As shown, the brake pad mold mobile rotary hot pressing production line of the present invention mainly includes a rotary plate 1, a mobile mold hot press machine 2, a hot press PLC controller 3, a centralized oil supply hydraulic system 4, and a hydraulic system PLC controller 5 , mold automatic moving device 6 and premix automatic weighing subpackaging and feeding device 8. A group of multiple ( figure 2 There are six) equal-density mobile mold heat presses 2, and each equal-density multi-cavity mobile mold heat press 2 is equipped with a heat press PLC controller 7 correspondingly. The mold automatic moving device 6 and the premix automatic weighing subpackaging and feeding device 8 are outside the rotary table. The hot press PLC controller 7, the centralized oil supply hydraulic system 4 and the hydraulic system PLC controller 5 are all installed on the rotary table 1. The operation of each equal-density mobile mold hot press 2 is automatically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com