Eco-paint in which goldfish can survive

An original ecology, goldfish technology, applied in the field of wall paint, can solve the problems of antibacterial, air purification, etc., and achieve the effect of reducing the toxicity of the coating film and secondary pollution, good fullness, and reducing the toxicity of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

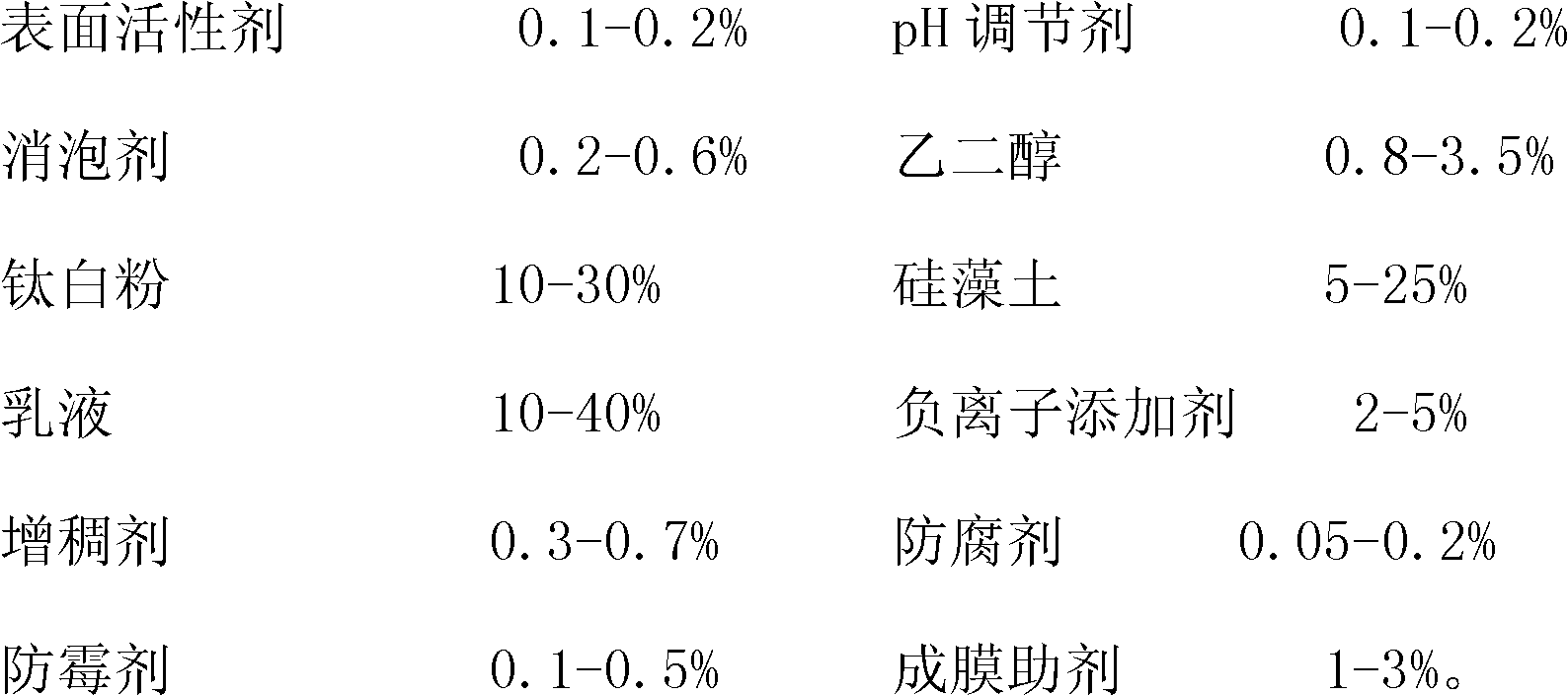

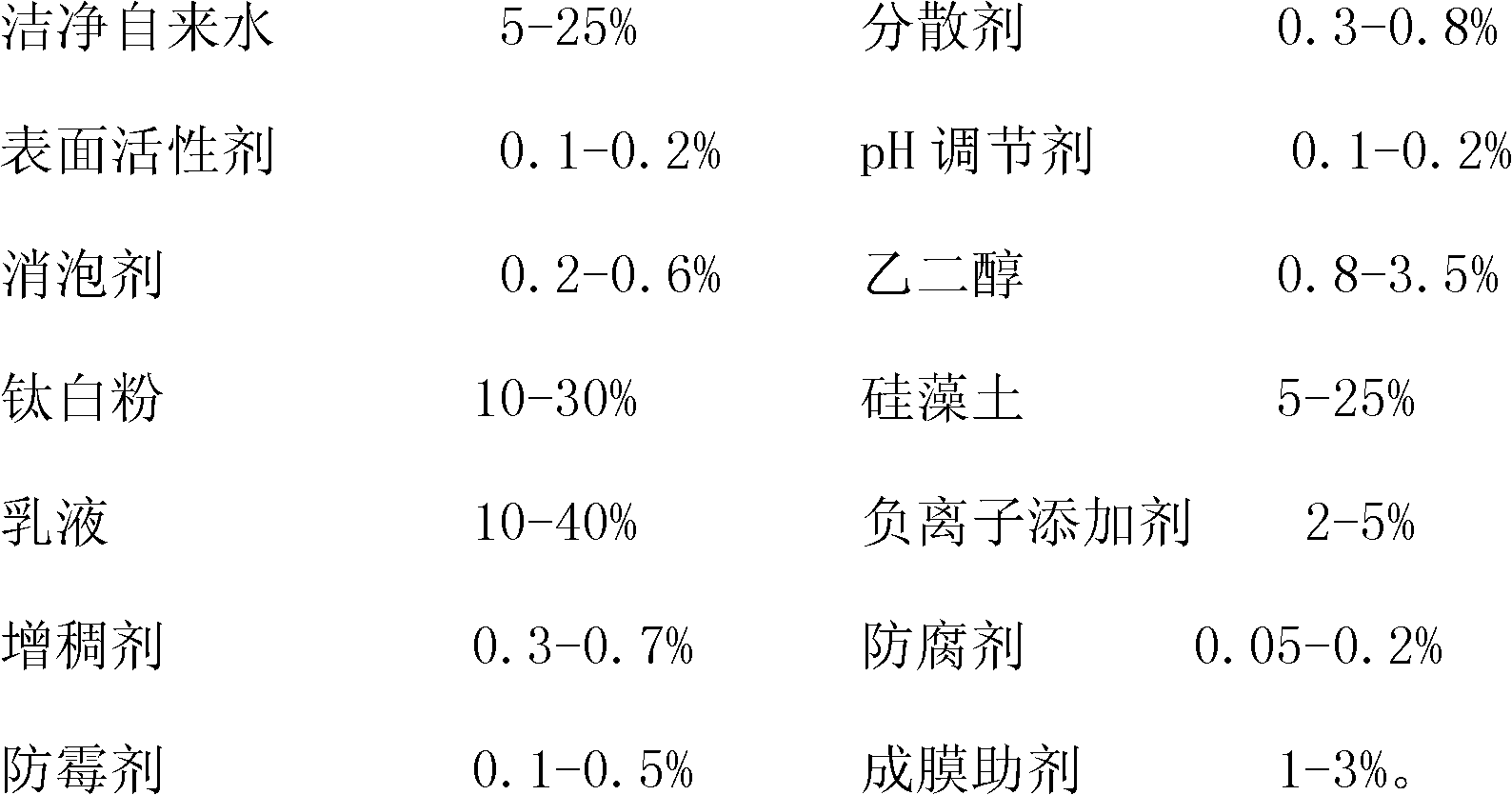

Embodiment 1

[0025] Weigh 5kg of clean tap water, 0.8kg of dispersant, 0.2kg of surfactant, 0.2kg of pH regulator, 0.2kg of defoamer, 0.8kg of ethylene glycol, 1kg of film-forming aid, and 30kg of titanium dioxide. Diatomite is 25kg, emulsion is 34kg, negative ion additive is 2kg, thickener is 0.3kg, preservative is 0.2kg, antifungal agent is 0.3kg, feed in order according to the conventional paint making process, each material is stirred evenly before Throw in a material, stir while feeding, and measure the viscosity after the material is uniformly dispersed to obtain the original ecological goldfish paint.

Embodiment 2

[0027] Weigh 25kg of clean tap water, 0.5kg of dispersant, 0.1kg of surfactant, 0.1kg of pH regulator, 0.6kg of defoamer, 3.5kg of ethylene glycol, 3kg of film-forming aid, and 16kg of titanium dioxide. Diatomite is 5kg, emulsion is 40kg, negative ion additive is 5kg, thickener is 0.7kg, preservative is 0.05kg, antifungal agent is 0.45kg, feed in order according to the conventional paint making process, each material is stirred evenly before Throw in a material, stir while feeding, and measure the viscosity after the material is uniformly dispersed to obtain the original ecological goldfish paint.

Embodiment 3

[0029] Weigh 20kg of clean tap water in proportion, 0.3kg of dispersant, 0.15kg of surfactant, 0.15kg of pH regulator, 0.5kg of defoamer, 2kg of ethylene glycol, 2kg of film-forming aid, 20kg of titanium dioxide, silicon 15kg of algae earth, 36kg of emulsion, 3kg of negative ion additive, 0.6kg of thickener, 0.1kg of preservative, and 0.2kg of antifungal agent, according to the order of conventional paint making process, each material is stirred evenly before casting A kind of material, stir while feeding, and measure the viscosity after the dispersion is uniform, and then the original ecological goldfish paint can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com