Separator and separation method thereof

A technology of separator and cyclone separator, which is applied in the direction of the device where the axial direction of the swirl can be reversed, the swirl device, etc., which can solve the problems of limited application range and inability to apply separation at the same time, and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

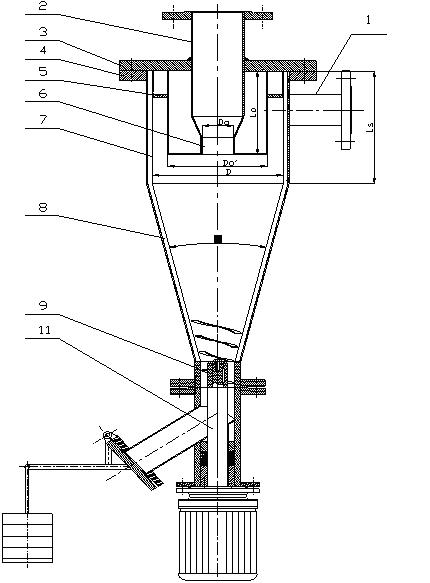

[0020] The separator of the present invention is divided into two categories: one is a separator for separating particles with a higher density than the medium, and the other is a separator for separating particles with a lower density than the medium. The first type of separator is a single inlet, which is composed of a cyclone separator, a collection tank and a screw unloader connected sequentially from top to bottom, and the collection tank may not be provided. The second type has two or more inlets that are symmetrical about the axis of the cyclone separator, which can be vertical or horizontal. The vertical type consists of a spiral unloader, a collection tank and a cyclone separator And the lower ones are connected successively, and the collecting tank can also be omitted. The specific instructions are as follows:

[0021] figure 1 and 2 It is a separator for separating particles with a higher density than the medium, with an unloader but without a collection tank, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com