Preposed external concurrent heating defrosting-preventing device

A front-mounted, heating device technology, applied in the direction of damage protection, condensate prevention, lighting and heating equipment, etc., can solve the problems of long defrosting time, insufficient defrosting, bad indoor environment, etc., achieve short defrosting time, Simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

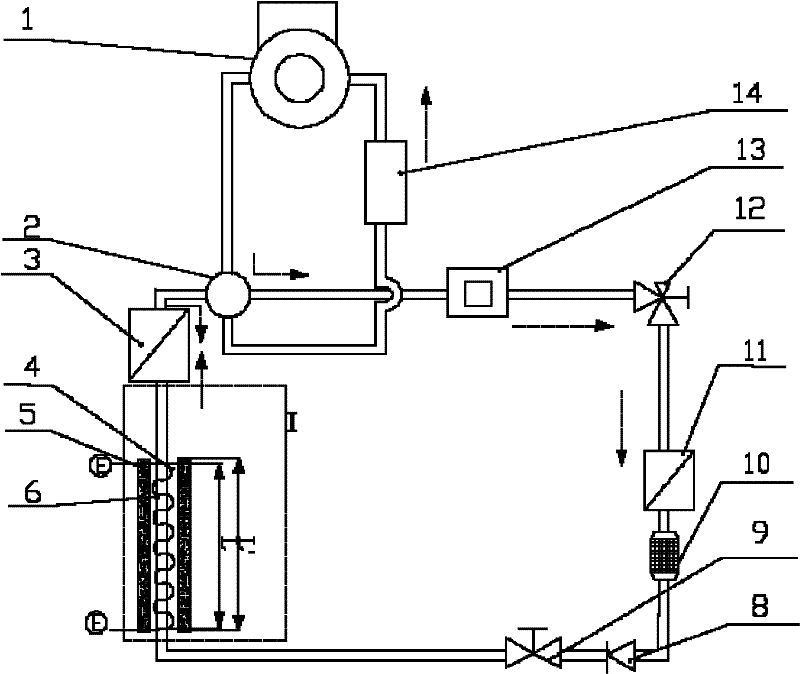

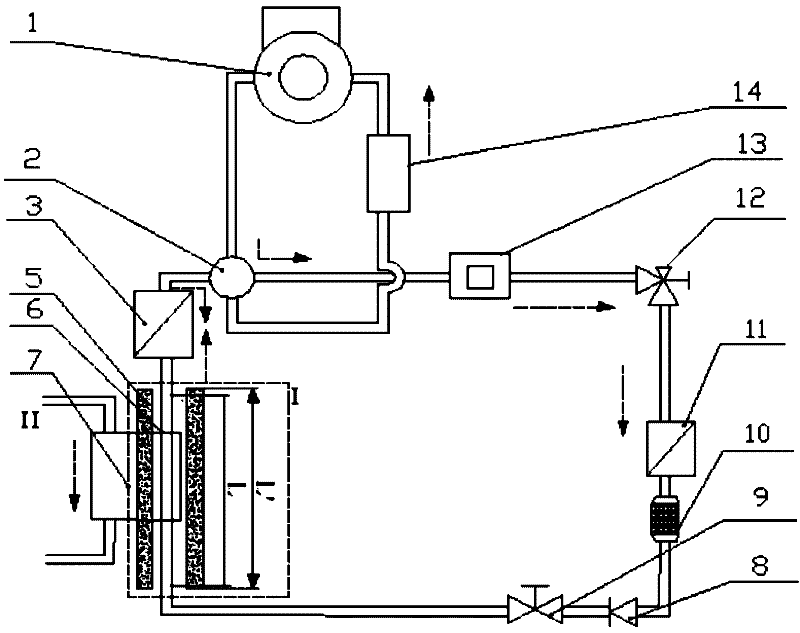

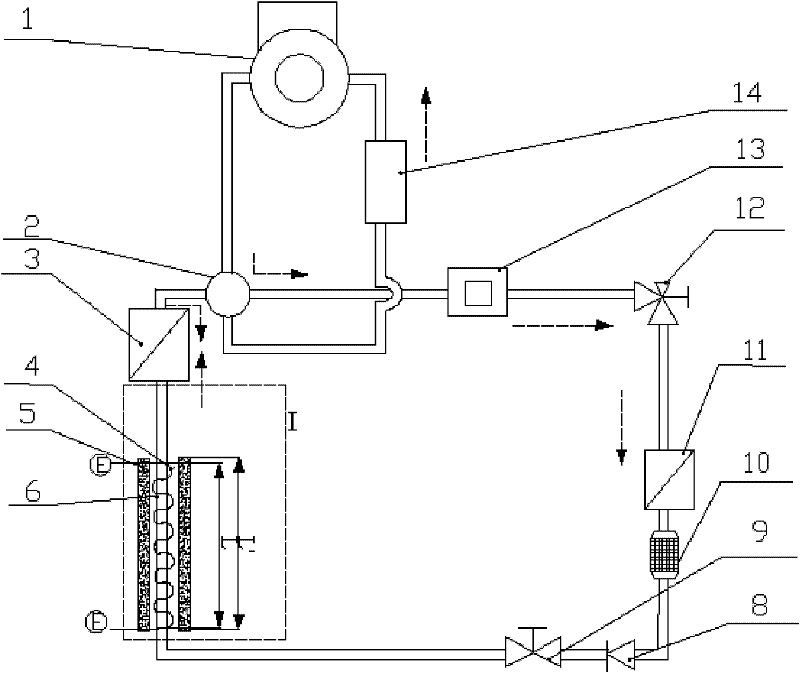

[0015] The first embodiment of the present invention is carried out on site according to figure 1 It can be completed, and the structure is simple and practical. It is a schematic diagram of an evaporator electric heating tube auxiliary heat defrosting air heat exchanger device based on the parameter frost growth law.

[0016] see figure 1 , one end of the compressor 1 outlet is connected to the high-temperature heat exchange side 11 through the four-way valve 2 and the muffler 13, and one end comes out of the compressor 1 outlet and passes through the four-way valve 2, and then returns to the compressor inlet through the liquid reservoir 14, and the high temperature One end of the heat exchange side 11 communicates with the outlet of the muffler 13 through the control solenoid valve 12, and the other end communicates with the dry filter 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com