Method for protecting thread in process for treating inner surface of double-sealing surface tube used for oil exploitation

A treatment process and thread protection technology, applied in the field of pipe fittings protection, can solve problems affecting the normal operation of the production line, affecting economic benefits, increasing production costs, etc., and achieves the effects of convenient and fast processing, saving storage space, and occupying less space

Active Publication Date: 2011-11-09

SHANGHAI TUBE COTE PETROLEUM PIPE COATING

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The production of thread protection methods in the prior art is based on the nesting principle, that is, the way that ordinary rubber thread protection rings are embedded in iron barrels, which determines the need to include surveying and drawing→raw material procurement→outsourcing processing→new tooling acceptance→new tooling trial→ The production of the thread protection method can only be completed in seven steps such as repair and remodeling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

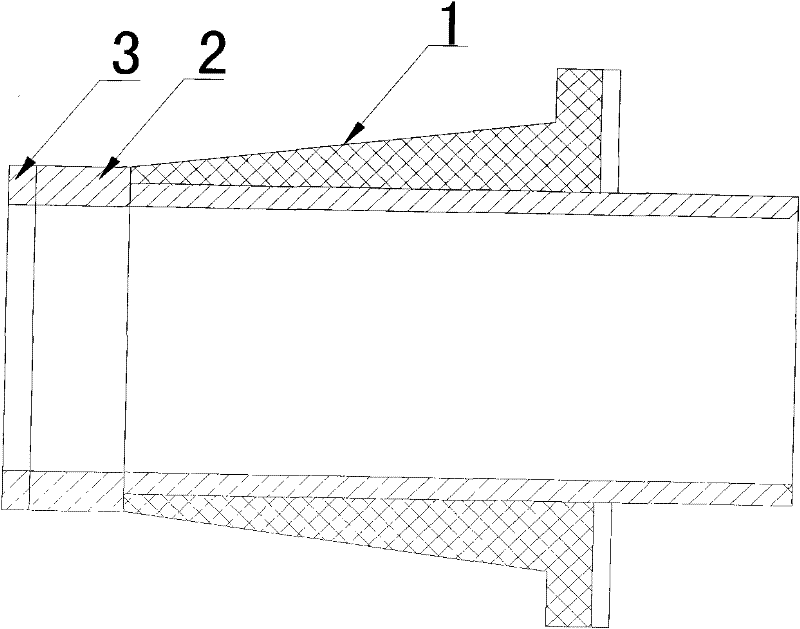

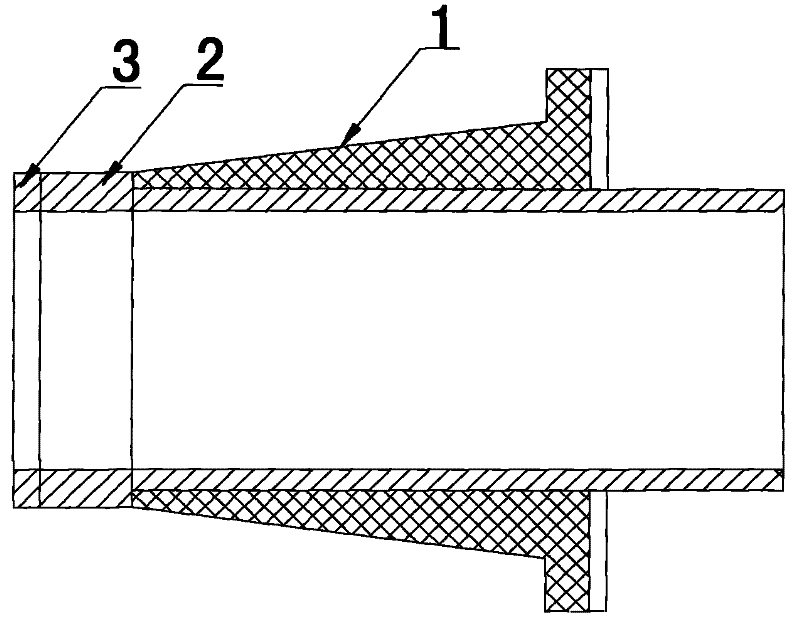

The invention provides a method for protecting a thread in a process for treating the inner surface of a double-sealing surface tube used for oil exploitation, comprising the following steps of: A, accurately measuring the effective thread length at a female terminal joint of the tube and the sectional area of an inner sealing surface; B, according to the measurement result, making a steel washerand a rubber washer which have the sectional areas consistent with the sectional area of the inner sealing surface; C, according to specification of the tube, selecting a shortened standard thread protector as a thread protection base; and D, sequentially placing the rubber washer, the steel washer and the thread protection base into the tube, and then treating the inner surface of the tube. By adopting the method provided by the invention, the processing cycle of a thread protector can be shortened, the production efficiency can be improved, the delivery time can be guaranteed, and the production cost can be reduced to the utmost extent. The thread in the process for treating the inner surface of the tube used for the oil exploitation can be protected by adopting an assembling and disassembling way.

Description

technical field [0001] The invention relates to a pipe fitting protection method, in particular to a thread protection method in the process of treating the inner surface of a pipe with double sealing surfaces for petroleum development. Background technique [0002] During the production and processing of the inner coating of pipes used in oil development with double sealing surfaces, it is necessary to protect the thread of the female end joint of the pipe and the inner sealing surface from damage when the inner surface of the pipe is treated, so a special thread protection method is required for protection. The production of thread protection methods in the prior art is based on the nesting principle, that is, the way that ordinary rubber thread protection rings are embedded in iron barrels, which determines the need to include surveying and drawing→raw material procurement→outsourcing processing→new tooling acceptance→new tooling trial→ The production of the thread protec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65D59/00

Inventor 曹育红肖九强徐晓旻李纯兵王建刚谢从振

Owner SHANGHAI TUBE COTE PETROLEUM PIPE COATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com