Catalyst components for olefin polymerization and preparation method thereof

An olefin polymerization and catalyst technology, which is applied in the field of catalyst components and their preparation, can solve the problems of large differences in microstructure, different distribution of active centers and active centers, and large differences in catalyst performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

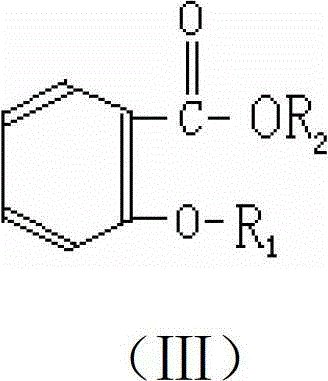

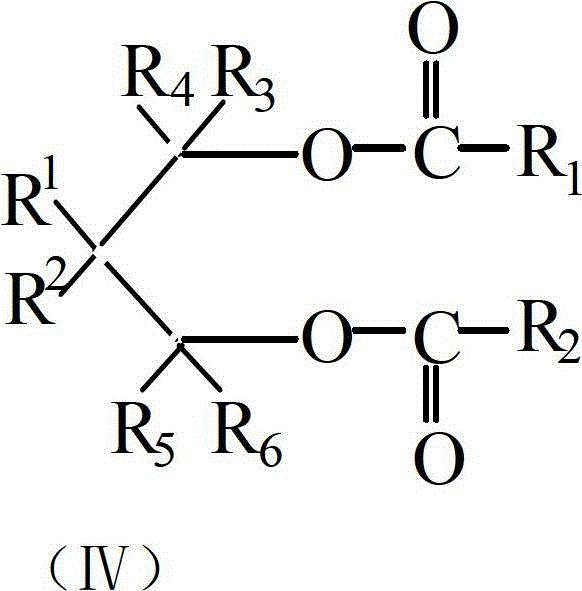

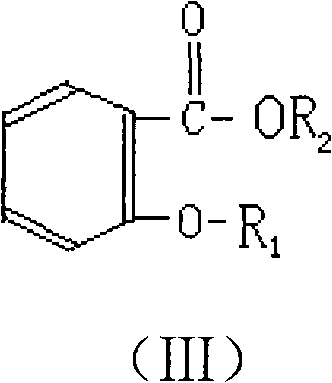

Method used

Image

Examples

Embodiment 1

[0069] Preparation of Spherical Catalyst Components

[0070] (A) In a 300ml stirred glass reaction bottle fully replaced by high-purity nitrogen, add 90ml of titanium tetrachloride and 10ml of hexane, cool to -20°C, add spherical magnesium chloride alcoholate carrier 8g (preparation method See Chinese patent CN1330086A),

[0071] (B) Under stirring, slowly raise the temperature step by step. When the temperature reaches 40°C, add 1.5ml of 2,4-pentanediol dibenzoate and 2-isopropyl-2-isoamyl-1,3 - Dimethoxypropane 1.5ml,

[0072] (C) Continue to heat up to 110°C, and after reaching the temperature, keep the temperature for 0.5h, remove the liquid by suction filtration,

[0073] (D) Add 100ml of titanium tetrachloride, raise the temperature to 110°C, keep the temperature for 1h after reaching the temperature, and remove the liquid by suction filtration. A total of three titanium treatments were added,

[0074] (E) Then wash five times with hexane, and obtain a spherical cata...

Embodiment 2

[0078] The preparation of spherical catalyst component: except 1.0ml of 2,4-pentanediol dibenzoate and 1.3ml of 2-isopropyl-2-isoamyl-1,3-dimethoxypropane are the same as the examples 1.

[0079] Propylene polymerization is with embodiment 1.

Embodiment 3

[0081] The preparation of spherical catalyst component: except 1.5ml of 2,4-pentanediol dibenzoate and 1.3ml of 2-isopropyl-2-isoamyl-1,3-dimethoxypropane are the same as in the example 1.

[0082] Propylene polymerization is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap