Thread guiding device for a thread changing device

A thread adjusting device and yarn guide technology are used in textile and papermaking, weft knitting, knitting and other directions, which can solve the problems of reducing the knitting system and the inability to use the knitting time economically, and achieve the goal of increasing the number and the width of the small structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

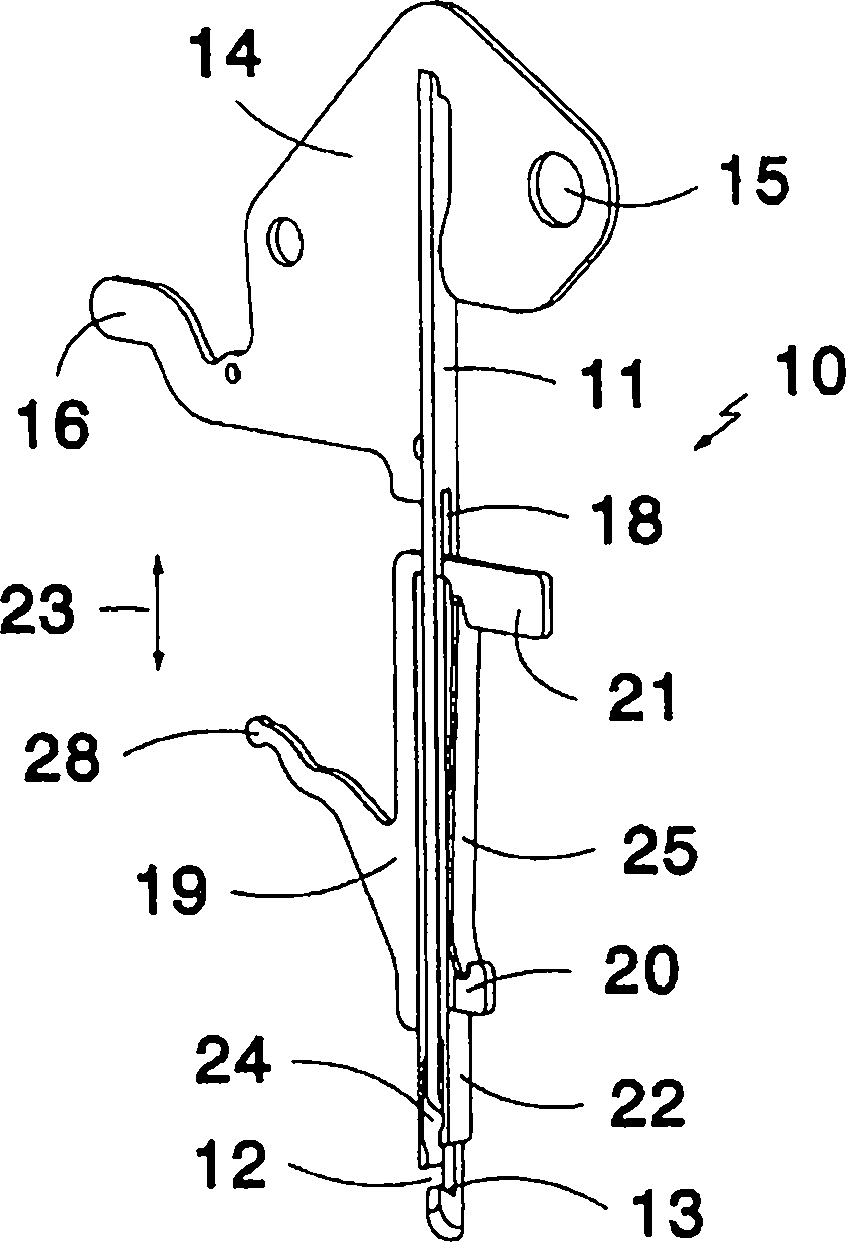

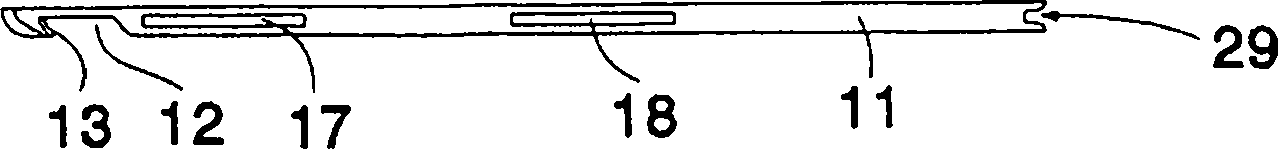

[0025] figure 1 The shown thread guide 10 has a finger 11 which has a thread receiving area 12 on its front end in the form of a substantially U-shaped recess, which is in particular composed of Figure 2b visible. The front boundary of the cutout 12 is formed as a cutting edge 13 . The rear end of the finger 11 is fastened to a pivot lever 14 which has a hole 15 for receiving a pivot axis of the thread adjustment device which is not described in detail here. Furthermore, it is provided with an actuating foot 16 for triggering the pivoting movement. In the finger body 11, two Figure 2b Visible longitudinal slits 17, 18, of which the longitudinal slit 18 is also figure 1 visible in . A guide element 19 is inserted in the longitudinal slot 17 , 18 and passes through the longitudinal slot 17 , 18 with two projections 20 , 21 . A clamping element 24 is arranged between the guide element 19 and the finger 11 . On the other side of the finger 11 opposite the clamping element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com